- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

NEWGOER

-

Model Number:

-

NG-ZYDP

-

Inside dimension:

-

450*1170*500mm

-

Materials:

-

SUS#304 stainless steel

-

Temperature range:

-

RT+10~70°C

-

Temperature uniformity:

-

±2°C

-

Temperature fluctuation:

-

±0.5°C

-

Temperature control:

-

PID SSR control

-

Standard Specimen Size:

-

48* 75*150mm

-

Product name:

-

UV Weather Aging Test Chamber

-

Function:

-

UVA UVB lamp aging test

-

Power supply:

-

220v 50/60HZ

Quick Details

-

Warranty:

-

1 year

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

NEWGOER

-

Model Number:

-

NG-ZYDP

-

Inside dimension:

-

450*1170*500mm

-

Materials:

-

SUS#304 stainless steel

-

Temperature range:

-

RT+10~70°C

-

Temperature uniformity:

-

±2°C

-

Temperature fluctuation:

-

±0.5°C

-

Temperature control:

-

PID SSR control

-

Standard Specimen Size:

-

48* 75*150mm

-

Product name:

-

UV Weather Aging Test Chamber

-

Function:

-

UVA UVB lamp aging test

-

Power supply:

-

220v 50/60HZ

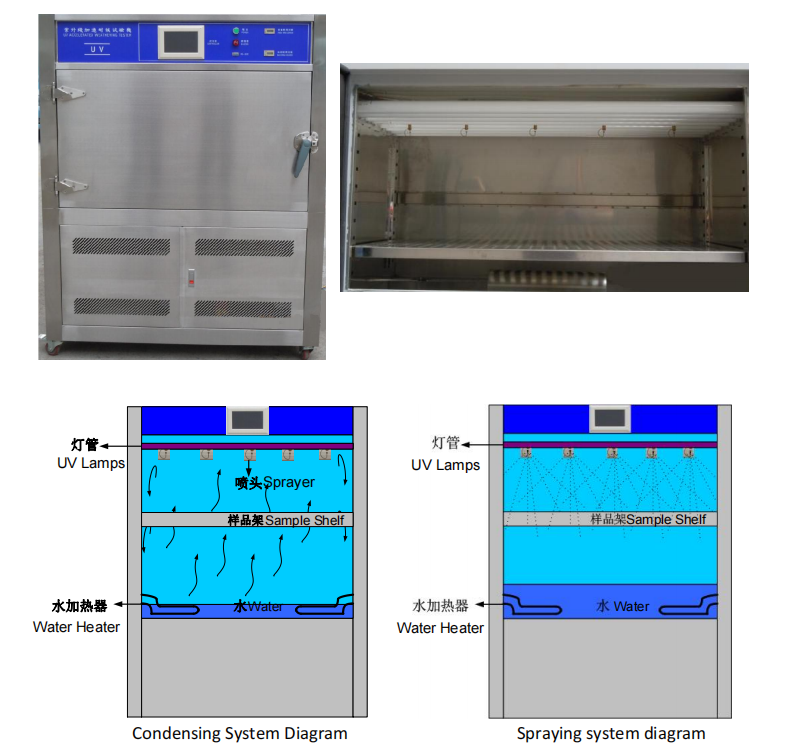

Customized Uv Accelerated Aging Test Chamber Uv Light Lamp Aging Chamber

Summary:

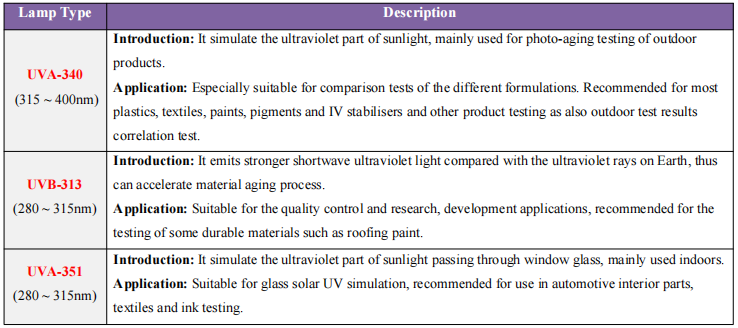

Standards:

EC61215, ASTM D4329: Standard Practice for Fluorescent UV Exposure of Plastics ;

Usages:

Features:

Speficiations:

|

Model |

NG-ZYD

|

NG-ZYDP

|

|

Inside dimension

|

500*1140*400mm

|

600*1140*500mm

|

|

Type

|

Tower Type

|

Box Type

|

|

Test specimen

|

Standard size: 75×150mm * 48pcs

|

Support Non-standard size

|

|

Materials

|

Inside and Outside SUS#304 stainless steel

|

|

|

Temperature range

|

RT+10~70°C

|

|

|

Temperature uniformity

|

±2°C

|

|

|

Temperature fluctuation

|

±0.5°C

|

|

|

Humidity range

|

≥75%RH

|

|

|

Controller

|

Touch screen programmable controller

|

|

|

Control mode

|

Balance temperature humidity control (BTHC)

|

|

|

Test cycle setting |

Illumination, condensation and water spray test cycle is programmable

|

|

|

UV Lamp

|

40W * 8 pcs

|

|

|

Wavelength ultraviolet light

|

UVA-340: 315-400nm Standard;

Or UVB-313: 280-315nm; UVA-351: 310-385nm for optional

|

|

|

Distance between the lamp

|

60~70mm

|

|

|

Distance from sample to lamp

|

50 mm

|

|

|

Irradiation intensity

|

0.3-1.2W/m 2

|

|

|

Water consumption

|

8L per day | |

|

Testing time |

0 ~ 999H, M, S continuously adjustable

|

|

|

Power

|

220V/50Hz /±10% 4.5KW

|

|

| Protection system |

Overload short circuit protection; Over temperature protection;

Electric leakage protection; Water lacking protection

|

|