- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

IP10 (4)

-

Material:

-

Acrylic (PMMA)

-

Color:

-

Transparent, Colored

-

Size:

-

9mm -- 200mm

-

Shape:

-

Round, Customized Shapes

-

Usage:

-

Home Decoration, Lamp Accessories etc

-

Name:

-

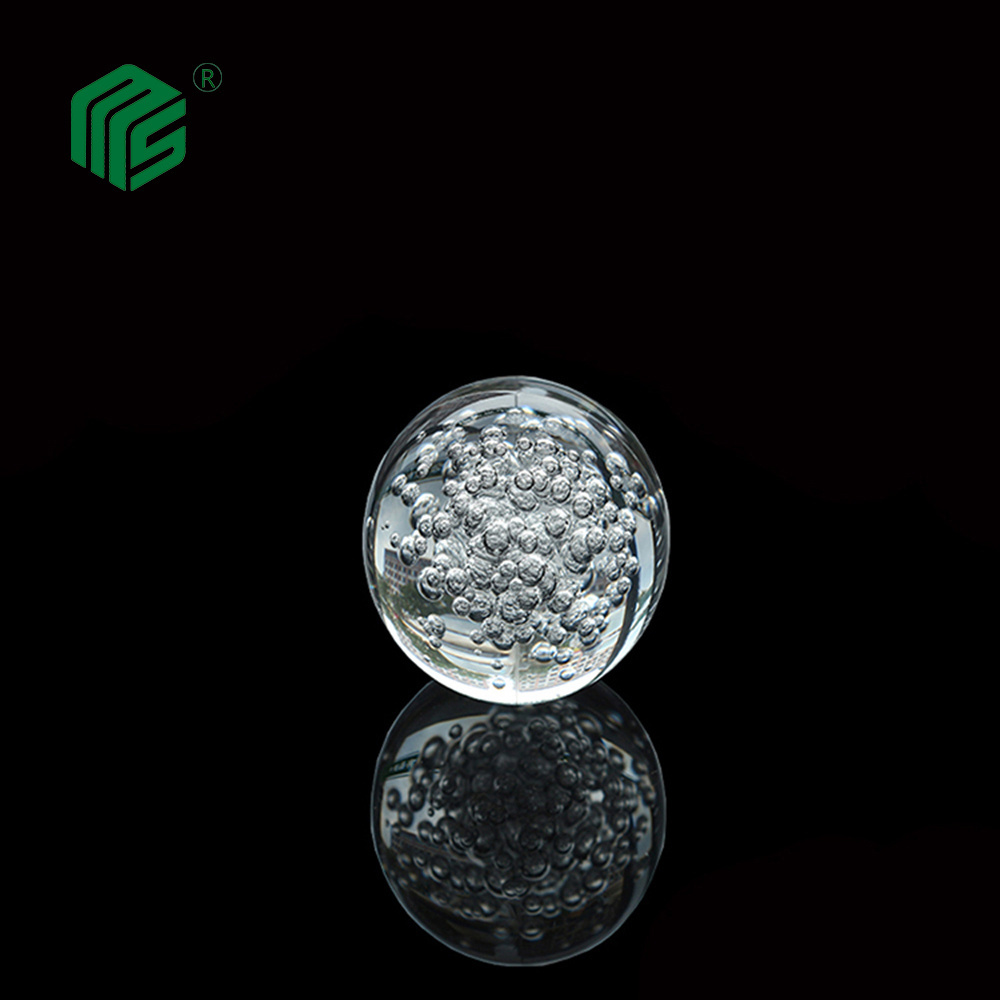

Transparent Large Diameter Acrylic Clear Colored Bubble Ball Sphere

-

Feature:

-

High Strength

-

Type:

-

Solid

Quick Details

-

Processing Service:

-

Moulding, Polishing, Sandblasting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Mingshi

-

Model Number:

-

IP10 (4)

-

Material:

-

Acrylic (PMMA)

-

Color:

-

Transparent, Colored

-

Size:

-

9mm -- 200mm

-

Shape:

-

Round, Customized Shapes

-

Usage:

-

Home Decoration, Lamp Accessories etc

-

Name:

-

Transparent Large Diameter Acrylic Clear Colored Bubble Ball Sphere

-

Feature:

-

High Strength

-

Type:

-

Solid

Product Description

Injection Molding is a manufacturing process for producing parts in large volume. It is most typically used in mass-production processes where the same part is being created thousands or even millions of times in succession.

The principal advantage of injection molding is the ability to scale production en masse. Once the initial costs have been paid the price per unit during injection molded manufacturing is extremely low. The price also tends to drop drastically as more parts are produced.

Detailed Images

Product details

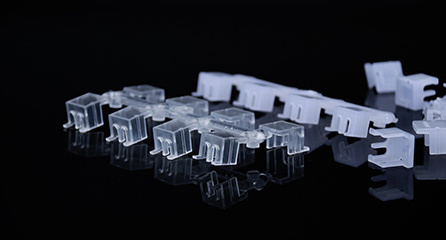

End cap for diffuser

Lampshade

Lighting lenses

Handles

Stair handrail

Lampshade

Certificate

All of our products are ROHS

approved.

Related Products

Company Introduction

Guangdong Mingshi Plastic Technology Co.,Ltd was founded in 2004, which is located in Henglan town, Zhongshan city, Guangdong province, China. Mingshi is a high and new technological enterprise of various types of acrylic and polycarbonate with R&D, manufacturing and sales integrated.

Mingshi specializes in extrusion and injection including profiles, lenses, tubes, rods, balls, handles, etc. And also specializes in related deep processing including CNC engraving, CNC lath, polish, roasted bending forming, bonding, gong side, chamfer, sand blasting and other post-processing. Our products are widely used in the industry of lighting, furniture, advisement medical equipment, building, decoration, bathroom, gift etc.

Mingshi Plastic has advanced production equipment and a number of experienced professionals engaging in core technology development, production management and quality control. Over the 15 years, our company focuses on strict management, upholds the belief of ‘existence with quality, development with credit standing’ and is marching steadily toward the development direction of specialization, large scale and internationalization.

Packing&Shipping

FAQ

Q1: Are you a manufacturer or trading company?

A: We are a professional extrusion, injection molding and processing manufacturer with more than 10 years of experience.

Q2: Can you work with customers to develop new products?

A: We would love to share professional experience with you.

Q3: How can you ensure the mass production is consist with signed sample?

A: All the process parameters are filed by our engineer department and the signed sample will be regarded as the quality standard.

Q4: What is your MOQ?

A: For some standard plastic products, MOQ is not required. For more details, please contact us.

Q5: What is delivery time?

A: 15 days.

A: We are a professional extrusion, injection molding and processing manufacturer with more than 10 years of experience.

Q2: Can you work with customers to develop new products?

A: We would love to share professional experience with you.

Q3: How can you ensure the mass production is consist with signed sample?

A: All the process parameters are filed by our engineer department and the signed sample will be regarded as the quality standard.

Q4: What is your MOQ?

A: For some standard plastic products, MOQ is not required. For more details, please contact us.

Q5: What is delivery time?

A: 15 days.

Hot Searches