Sealing knives, according to customer requirements, can adjust the sealing edge and tightness of the sealing can make customers more satisfied.

Machine characteristics:

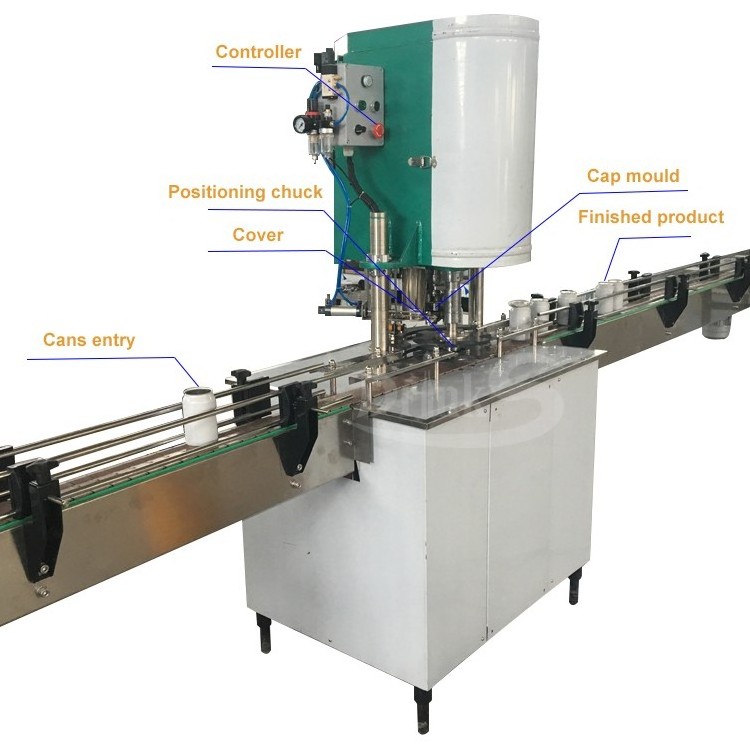

Technical features of cans and cans: The cans are mainly used for the sealing of tin cans, aluminum alloys, plastics and other cans. It has the automatic stop device with cans without cover, no cans without cover, in and out cans and other faults. It is the ideal equipment for canned food factory, beverage factory and winery sealing. The cover portion seals the lid to the jar that has been filled with the product and is transported by the conveyor chain to the subsequent process. The sealing roller is quenched with high hardness alloy (hrc>62), and the sealing curve is precision machined by optical curve grinding to ensure the quality of the sealing and ensure the normal operation of the machine. This machine has a can bottom cover, no cans and no cover control system to ensure the normal operation of the machine and reduce the cover loss rate. The aluminum cover is manually placed in the chute by the cover gravity and the thruster for the lower cover, and the detection switch is installed in the chute to ensure that the cover can be stopped when the cover is missing. According to the tank type of different heights, the capping machine can be manually raised and lowered to meet the requirements.

Q1:What are the characteristics of the machine?

A1:

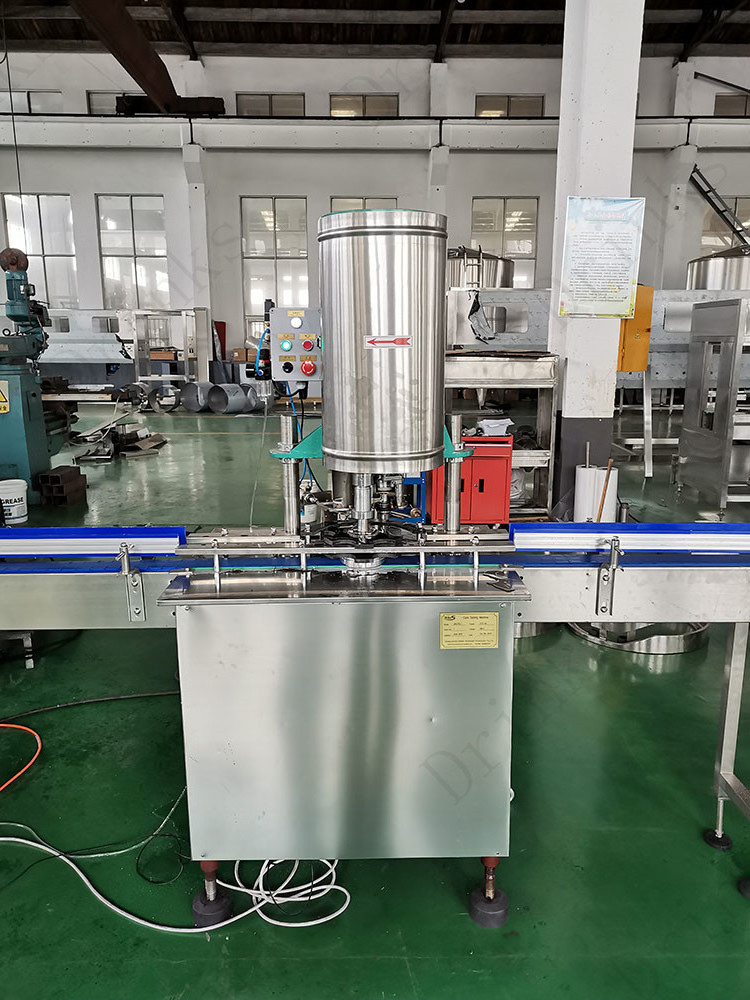

1. The main body of this product is made of stainless steel, which is beautiful in appearance and meets the design requirements of most standard production workshops.

2. It adopts single motor operation, precision machining of various parts, production technology and technology, etc. After long-term precipitation and continuous improvement by the company, it has the advantages of low noise and low failure rate.

Sealing knives, according to customer requirements, can adjust the sealing edge and tightness of the sealing can make customers more satisfied.

The automatic lower cover is customized according to the customer's cover size, and the pneumatic lower cover system makes the work efficiency higher and more stable.

Positioning the conveyor belt, better connected to other production equipment, production efficiency is higher.

This machine is designed with adjustment parts for a variety of cans of different heights.

Q2: What is the range of output I can choose?

A2:

We have a variety of models available for customers to choose from, different capacity, we have different models recommended to customers.

|

Model

|

FKJ-1

|

FKJ-4

|

|

Production capacity (BPH)

|

1000-2000

|

4000-5000

|

|

Number of sealing possitions

|

1

|

4

|

|

Can height (mm)

|

50-133

|

50-133

|

|

Can diameter (mm)

|

52-100

|

52-100

|

|

Power (kw)

|

1.1

|

4

|

|

Overall dimensions (mm)

|

930*700*1850

|

1530*1680*1980

|

|

Weight (kg)

|

380

|

1500

|

Q3:Which products can you seal this machine?

A3:

In the figure below, we show a detailed introduction of some physical products, you can choose according to your needs.

If you have any questions, you can click "Send" to send us an inquiry, we will solve the problem online for you 24 hours a day.

Milk

Beer

Gas-containing beverage

Canned tuna

Food

Health care products

1. Q: Are you a factory or a trading company?

A:

We are a factory that produces a complete set of raw water treatment equipment and juice filling production lines. Our company has 5 years of production experience. The factory area is approximately 5,000 square feet. Customers in nearly 20 countries have used our equipment.

2. Q: Where is your factory? How do I get there?

A:

The address of our company is Leyu Town, Zhangjiagang City, Jiangsu Province. It is about one and a half hours drive from Shanghai Hongqiao Airport and 40 minutes from Wuxi High Speed Rail. Welcome Chinese and foreign customers to visit our company.

3. Q: How long is the warranty period of your machine?

A:

After the device is accepted, it provides a 12-month warranty, the control system provides a 12-month warranty, free accessories and timely and effective service. After the warranty period, provide extensive technical support and lifetime after-sales service.

4. Q: What are the characteristics of your company?

A:

We provide turnkey projects for our customers, including pre-sales and after-sales services, providing complete production lines, designing bottle samples, providing layout drawings free of charge, providing auxiliary material supply information, machine installation and commissioning, and employee training.

|

Size

|

980 (L) * 820(W) * 2000 (H)mm

|

|

Weight

|

400kg

|

|

|

The normal packaging is a wooden box (size: L*W*H). If exported to European countries, the wooden box will be fumigated. If the container is too tight, we will use PE film packaging or packaging according to customer's special requirements.

|