- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1400mmX800MMX1600MM

-

Weight:

-

1500kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

PP/PE

-

Application:

-

agglomerating pp pe.HDPE, LDPE film

-

Color:

-

Blue or customized

-

Raw material:

-

pp pe film

-

Output:

-

200-300kg

-

Motor brand:

-

Jiangsu

-

Temperature controller:

-

Japan OMRON

-

warranty:

-

1 year

-

package:

-

by standard wooden box

-

shipment:

-

by LCL

-

Max. Capacity:

-

200-300kg/h

-

Certification:

-

CE certificate

-

Power:

-

55KW

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Friend Plastic Agglomerator/Plastic Densifier Machine

-

Model Number:

-

TLJ300 Plastic Agglomerator/Plastic Densifier Machine

-

Voltage:

-

380V or customized

-

Dimension(L*W*H):

-

1400mmX800MMX1600MM

-

Weight:

-

1500kg

-

Warranty:

-

1 Year

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Material:

-

PP/PE

-

Application:

-

agglomerating pp pe.HDPE, LDPE film

-

Color:

-

Blue or customized

-

Raw material:

-

pp pe film

-

Output:

-

200-300kg

-

Motor brand:

-

Jiangsu

-

Temperature controller:

-

Japan OMRON

-

warranty:

-

1 year

-

package:

-

by standard wooden box

-

shipment:

-

by LCL

-

Max. Capacity:

-

200-300kg/h

-

Certification:

-

CE certificate

-

Power:

-

55KW

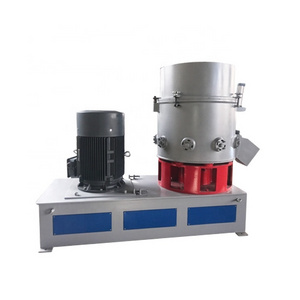

Plastic Agglomerator/Plastic Densifier Machine

1. Features of Plastic Agglomerator/Plastic Densifier Machine

The Plastic Agglomerator/Plastic Densifier Machine is used to granulate the thermal plastic films, PET fibers, whose thickness is less than 2 mm into small granules & pellets directly. The soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fibers and other thermoplastics are suitable for it.

2. Working Principle of Plastic Agglomerator/Plastic Densifier Machine

When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. The water will be evaporated off quickly and the surface temperature of material being crushed drop down quickly also. So the material being crushed will become small particles or granules.

Features of Plastic Agglomerator/Plastic Densifier Machine:

Plastic Agglomerator/Plastic Densifier Machine blade base and blade can be disassembly It is easy to clean and

maintenance.

² P ot is welded of high quality stainless steel and blade with special alloy tool stee

² Lower noise and high capacity. Strong design of double-bearing for holding the main shaft

Applicable material of Plastic Agglomerator/Plastic Densifier Machine: Soft PVC, LDPE, HDPE, PS, PP, foam PS, PET fib er s and other thermoplastics,etc.

Technical parameters of Plastic Agglomerator/Plastic Densifier Machine :

( TLJ series is mainly used to produce PE, PP and other plastic film etc.)

|

Model |

TLJ-100 |

TLJ-200 |

TLJ-300 |

TLJ-500 |

TLJ-600 |

TLJ-800 |

|

Volume (L) |

100 |

200 |

300 |

500 |

600 |

800 |

|

Effective Volume (L) |

75 |

150 |

225 |

375 |

450 |

600 |

|

Main Motor (kw) |

37 |

55 |

75 |

90 |

90-110 |

110 |

|

Rotation Blade |

2 |

2 |

4 |

4 |

4 |

4 |

|

Fixed Blade |

6 |

6 |

8 |

8 |

8 |

8 |

|

Capacity (kg/h) |

100 |

150 |

200 |

300 |

400 |

550 |

|

Weight (kg) |

1000 |

1200 |

1800 |

2500 |

2700 |

3000 |

|

Dimension (m) |

1.7*0.75*1.5 |

1.7*0.85*1.5 |

2*0.85*1.6 |

2.3*0.95*1.7 |

2.3*1.1*1.75 |

2.5*1.25*1.8 |

|

Pot Material |

Stainless steel |

|||||

|

Blade material |

SKD-11 |

|||||