- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Weight (KG):

-

17500 kg

-

Power (kW):

-

132

-

MACHINE:

-

TIRE RECYCLING MACHINE

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mixer

-

Model Number:

-

xkp610

-

Voltage:

-

380v

-

Weight (KG):

-

17500 kg

-

Power (kW):

-

132

-

MACHINE:

-

TIRE RECYCLING MACHINE

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

After Warranty Service:

-

Video technical support

-

Certification:

-

CE ISO

Product Description

Description:

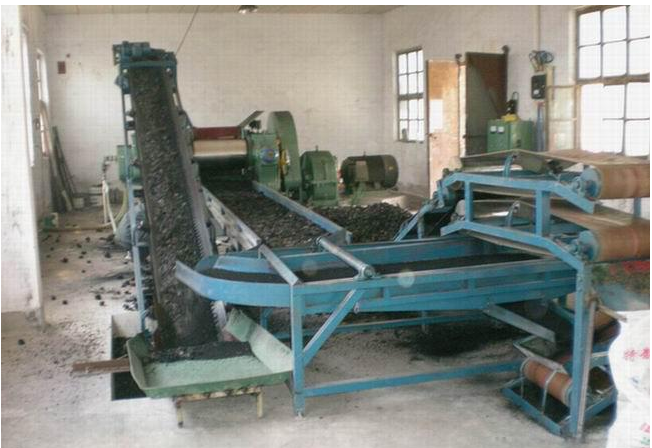

Waste tire recycling machine: This line mainly consists of mainframe (rubber crusher), powder screener, and magnetic separator.

Step1: Through the decomposition of waste tire by Waste tire breaking down machines set, the tire processed into about 3.5 cm square pieces first;

Step2: By the rubber crusher shredding process to get rubber powder or particles with wire and fiber mixed inside.

Step3: Using the powder vibrating screener, magnetic separator to completely separate wire and fiber and tire rubber powder or granules.

Through the conveyor belt with two sieve beds filter out the fine material and then by magnetic roller, magnetic separation of steel wire and fiber, finally, getting the pure rubber powder.

Specification

These machines set mainly consists the following equipment:

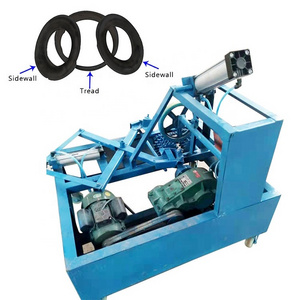

1. Tire ring cutter XQK-800

This machine is used to cut steel tire sidewall in order to do separation of the next step. Tire placed Disc platform, rotate the middle of hand-wheel, three-jaw card holder will be jammed solid inner tire, start power, work platform rotation, cutting tools as needed into the knife, slowly cut into the tires, step by step, until cut sidewall of the tire. This is first step of recycling waste tire.

|

motor

|

Range of process

|

Capacity /hour

|

Dimension

|

weight

|

|

2.2KW

|

750-1200mm dia tire

|

25-30 tires /hour

|

1300*900*1480 mm

|

0.6 ton

|

2. Rubber bar cutter

This machine is utilized to cut radial tire which has been removed one side-wall into a certain sized of rubber strip.

2 disc cutters are of special materials, hard and durable, can be used repeatedly grinding for no more than 1200mm dia wire tires.

|

Motor power

|

capacity

|

Process tire dia

|

Material processed size

|

dimension

|

weight

|

|

5.5KW

|

20 tires/hour

|

Less than 1200mm

|

35-55mm

|

1230*650*1580

|

0.8 ton

|

Rubber block cutter can cut the tire strip cut by bar cutter into lump type. The cutter is of alloy, capacity is 9-11 tons per day. The knife is not shaper, can be repeated grinding.

|

Motor

|

capacity

|

Size of processed materials

|

Dimension of the machine

|

weight

|

|

7.5KW

|

0.8-1ton/hour

|

35*35mm

|

780*550*1210mm

|

0.6ton

|

Ⅱ. Main machine group

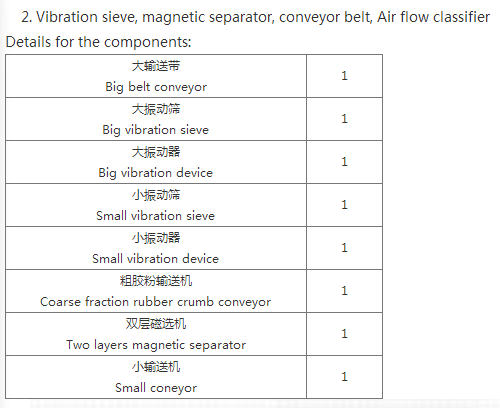

The machines set consist of rubber crusher and auxiliary machine. The auxiliary machines mainly consist of vibration sieve, rubber block conveyor, rubber powder filter screener, powder materials conveyor; steel wire magnetic separator. These auxiliary machines works together to achieve the production process flow.

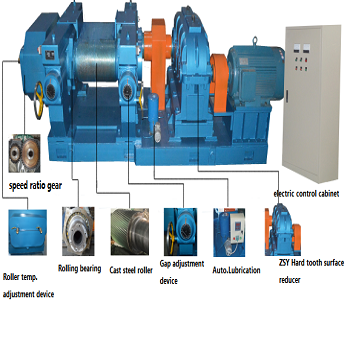

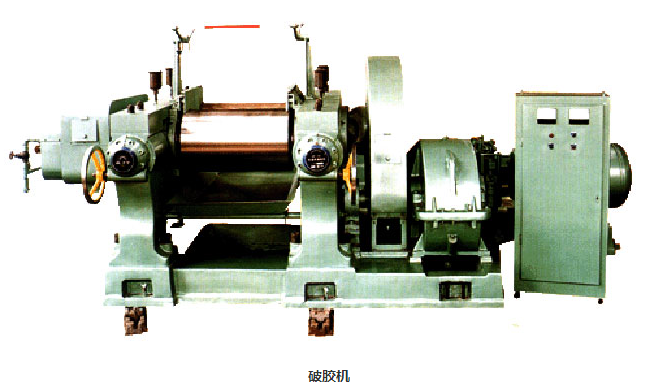

1. The rubber crushing mill: It is mainly used to crush the rubber lump, soles and rubber leftover materials to get the rubber powder or rubber granules.. The machine uses alloy chilled cast iron roller, the surface of hard wear-resistant, roll after roll of groove, cavity processing, so that the roll surface temperature uniformity; with overload protection and emergency braking device, safe and reliable; using hand-wheel adjustable rollers tube spacing, easy to operate.

Hot Searches