- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

QIANGDI

-

Application:

-

PLASTIC BOTTLE WASHING

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

850*850*1300MM

-

Power (kW):

-

0.55

-

Weight (T):

-

0.5

-

suitable bottle height:

-

can be adjusted

-

suitable bottle diameter:

-

can be adjusted

-

Conveyor belt height:

-

1300mm

-

Water consumption:

-

1 ton/h

-

pressure:

-

0.3Mpa

-

Washing heads:

-

32heads

-

Machine Material:

-

SUS304

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO

Quick Details

-

Machine Type:

-

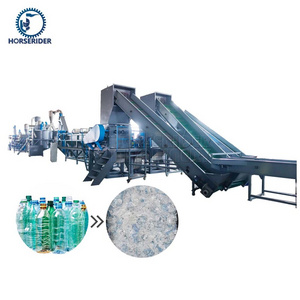

PP PE Bottle Washing Line

-

Max.Production Capacity (kg/h):

-

300

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

QIANGDI

-

Application:

-

PLASTIC BOTTLE WASHING

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

850*850*1300MM

-

Power (kW):

-

0.55

-

Weight (T):

-

0.5

-

suitable bottle height:

-

can be adjusted

-

suitable bottle diameter:

-

can be adjusted

-

Conveyor belt height:

-

1300mm

-

Water consumption:

-

1 ton/h

-

pressure:

-

0.3Mpa

-

Washing heads:

-

32heads

-

Machine Material:

-

SUS304

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support

-

After Warranty Service:

-

Spare parts

-

Local Service Location:

-

Egypt, Canada, Turkey, United Kingdom, United States, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Japan, Malaysia, Australia, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, Romania, South Africa, Kazakhstan, Ukraine, Kyrgyzstan, Nigeria, Uzbekistan, Tajikistan

-

Certification:

-

ISO

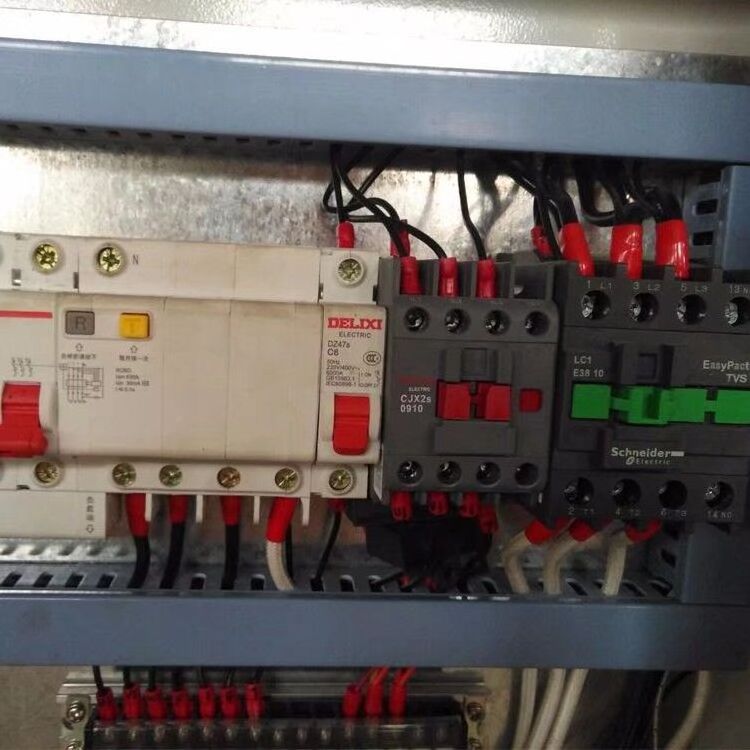

Plastic Glass Bottle Washing Machine/Wine Bottle Washer

The QD-32 bottle-punching machine produced by our factory is a newly designed one which combines the structural principle of domestic and foreign bottle-punching machines and according to the actual requirements of users. This machine is a necessary equipment before liquid filling. The water dividing valve is made of non-polluting material, which meets the requirements of food equipment.

This machine features:

<1>.the outer wall of the bottle is sprayed, the inner wall is washed, and the flushing bottle is clean and sanitary.

<2>.Use low-pressure pump boosting cycle to flush bottles with low water consumption.

<3>.The structure is simple and the maintenance is convenient.

<4>.Labor-saving, high production efficiency and wide application of bottle type (replacement of different bottle holders can be used for wide-mouth bottles and fine-mouth bottles).

Principle of bottle-punching.

1. The outer wall of the bottle is sprayed by a sprinkler, and the spray pressure can be adjusted by a spray switch. (The external water pressure of this machine should be higher than 0.1 Mpa. If it is lower than this pressure, it should have its own pressure pump. )

2. When the inner wall is flushed, the lower valve body is stationary and fixed on the bracket, and the upper valve body rotates simultaneously through the nozzle and the upper plate of the flushing bottle. When the water intake hole of the lower valve body is connected, the water is pressurized by the nozzle to flush the inside of the bottle.

The machine is suitable for cleaning bottles of various materials and shapes.

| Product name | QD-24 type manual bottle washer | QD-32 type manual bottle washer |

| Washing heads | 24 | 32 |

| Work efficiency | 1800-2400 BPH | 2500-3000 BPH |

| Motor power | 0.55KW/220V | 0.75KW/220V |

| Suitable bottle height | 120-350mm | 120-350mm |

| Suitable bottle diameter | 40-90mm | 40-90mm |

| Working pressure | 0.2-0.3Mpa | 0.2-0.3Mpa |

| Dimension(L*W*H) | D850×1300mm | D980×1300mm |

| Machine Weight | 180kg | 240kg |

Our factory is a manufacturer that designs, manufactures and installs a complete set of liquid packaging production lines. Our employees will recommend machines according to your budget. Our technicians will set up and arrange machines according to the area of your factory, make full use of and save space, improve production efficiency and reduce costs. Our factory has passed ISO and CE certification to ensure that it meets the industry's highest standards.

We provide a variety of semi-automatic bottle blowing machines, washing machines, filling machines, including single punch capping machine, piston filling machine, corrosive filling machine, gravity filling machine, single plug capping machine, semi-automatic capping machine. Natural gas mill, fully automatic in-line shaft capping mill, rotary capping mill, induction capping mill, vacuum capping mill. The labeling machine includes shrink sleeve labeling machine and self-adhesive labeling machine, PET blow moulding machine, shrink packaging machine, water treatment and reverse osmosis system. We provide design, manufacture, installation and training of one-stop filling and packaging equipment.

Our machines are widely used in beverages, food, household products, personal care products, chemical products and so on. How to choose the right equipment is a huge challenge for start-ups or some customers who want to expand their business. It depends on many factors, including liquid characteristics, container shape and size, cover geometry and size, speed and so on. Single-punch filler is specially designed for water, carbonated soft drinks, juices, drinks, tea, milk and yogurt. Gravity filling machine is suitable for free flow. In liquid, piston filling machine is most suitable for concentrated liquid with or without particles. Corrosive liquid filling machine is specially designed for corrosive liquid filling. Single filling machine is an ideal solution for small bottles and bottles. You can click on any link that best describes your industry.

We are committed to providing quality and complete one-stop service, we hope to provide you with the best performance machines at the most favorable prices and the shortest delivery time. Customer first is our goal. Whether you are a start-up company or a large company, we are willing to grow and develop with our customers and always be with you.

We will design accurate factory layout design according to customers' The measure of factory area; if the customer needed, we could make workshop design with electric power, water supply, gas power, material storage, final storages, workers’ restroom, etc.

If customer require, Our engineer will go to customers' factory for the commissioning service. 1-2 of our engineer will go to your factory to install and adjust the processing line to realize normal production at shortest time.

Our engineers have responsibility to train and teach the workers how to operate, clean, maintain the repair all the machine, until the worker could well operate the production line.

It normally costs 10 days for the commissioning service, and we supply 1 year guarantee from the date of completion of commissioning service.

The engineer’ s round-trip flight tickets, accommodation and daily salary $100 are on client ’ s account.

C: Are you a manufacturer or trade company?

F: We are a manufacturer in beverage machine field more than 10 years,Welcome to visit our website and factory.

C: What's your product ranges ?

F: 1.Drink water/juice/carbonated drink filling line.

2.PET small bottle or big barrel like 5 gallon water / can beverage / glass bottle beverage filling line,

3.Water, beverage and carbonated drinking treatment line.Performs blowing machine and caps injecting moulding machine .

4.After packing system(label machine, PE film shrink packing machine, carton machine etc.

C: Does your factory have any certification?

F: We are certified by CE and ISO.

C: Before sending a quotation, What information shall be provided?

F: 1. What kind of beverage do you want to produce?

2. How about bottle volume? 250ml, 330ml, 500ml, 750ml, or else?

3. Production capacity requirement, how many bottles per hour?

4. Raw water analysis report if you have.

5. How about your electric power system for 3 phase, it is 3 pahse, 380V, 50Hz.in China

C: If bottle size changes, is it possible just do some adjustment on machine according to new bottle size?

F: Yes, just need to change some relevant parts. We have a video for teaching how to operate.