- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

500

-

Voltage:

-

220V/380V

-

Rated Capacity:

-

40-200KVA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

Customized

-

Use:

-

Copper Wire Welding Machine

-

Product Name:

-

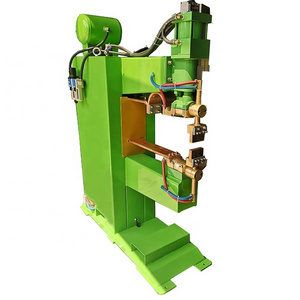

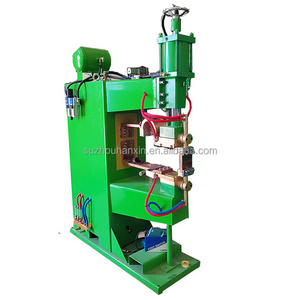

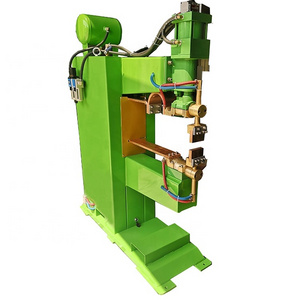

Point Welding Multi Head Spot Welding Wire Mesh Welding Machine

-

Machine type:

-

Automatic Multi Spot Welding Machine

-

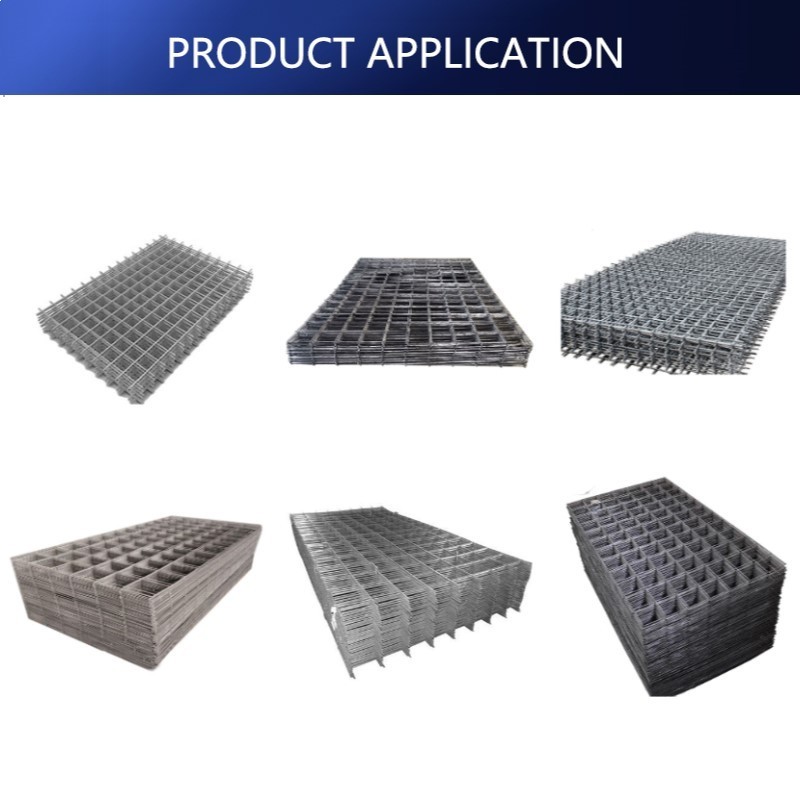

Application:

-

Automation Equipment

-

Function:

-

Spot Weldinng

-

Keyword:

-

Resistance Spot Welding Equipment

-

Welding material:

-

Steel Copper Aluminum

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support, Online support and Spare parts

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training

-

Certification:

-

ISO,CE

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

XinWeiHan

-

Weight (KG):

-

500

-

Voltage:

-

220V/380V

-

Rated Capacity:

-

40-200KVA

-

Rated Duty Cycle:

-

50%

-

Dimensions:

-

Customized

-

Use:

-

Copper Wire Welding Machine

-

Product Name:

-

Point Welding Multi Head Spot Welding Wire Mesh Welding Machine

-

Machine type:

-

Automatic Multi Spot Welding Machine

-

Application:

-

Automation Equipment

-

Function:

-

Spot Weldinng

-

Keyword:

-

Resistance Spot Welding Equipment

-

Welding material:

-

Steel Copper Aluminum

-

MOQ:

-

1 Set

-

After Warranty Service:

-

Video technical support, Online support and Spare parts

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training

-

Certification:

-

ISO,CE

ChengDu Xinweihan is one of the leading welding equipment manufacturer in china,

Specialized in manufacturing and provide customers with a complete set of welding solutions.

A R&D team of more than 20 engineers., and a 20000 sq.m manufacturer, which guarantees that we can offer customers the most professional welding advice and after-sales service.

And we have our own overseas technical service teams in many countries in Southeast Asia and South America to provide customers with on-site installation and maintenance services.

(Please contact us to ask if there is a technical team in your country)

Product Description

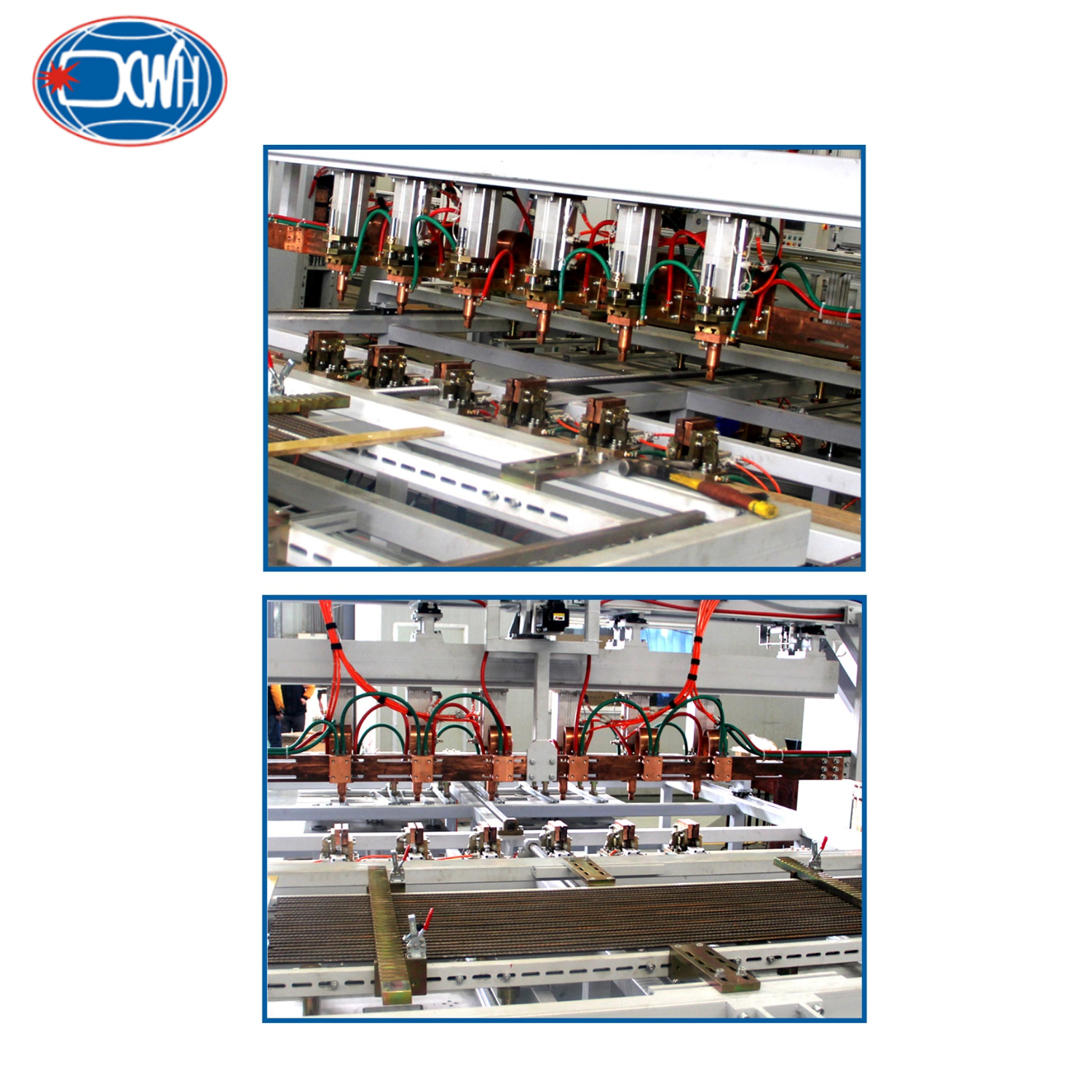

The steel bar/ wire mesh spot welding machine is equipped with a semi-automatic welding equipment suitable for steel bars and wire mesh, with simple operation and high productivity.

The multi head spot welding machine adopts the advanced structure of foreign equipment and fully combines with a semi-automatic welding equipment developed in the Chinese market that is completely different from the currently used semi-automatic welding equipment by various manufacturers. It completely overcomes the shortcomings of high labor intensity, low production efficiency, complex operation, large spatter, weak welding, high failure rate, and low automation of the original welding machine (electrode replacement is sufficient).

Technical Parameters

|

Item/Model

|

DN-40

|

DN-63

|

D(T)N-80

|

D(T)N-100

|

D(T)N-125

|

D(T)N-160

|

D(T)N-200

|

|

Rated power At 50%(KVA)

|

40

|

63

|

80

|

100

|

125

|

160

|

200

|

|

Rated primary power(V)

|

380

|

380

|

380

|

380

|

380

|

380

|

380

|

|

Secondary Voltage(V)

|

5.2

|

6.7

|

7.9

|

8.3

|

8.6

|

9.1

|

10.6

|

|

Rated frequency(HZ)

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

50/60

|

|

Max.Short Circuit Current(KA)

|

14

|

15

|

16

|

18

|

20

|

28

|

34

|

|

Max. weld power(KVA)

|

62

|

86

|

170

|

280

|

300

|

330

|

410

|

|

Throat(MM)

|

400

|

400

|

400

|

450

|

450

|

450

|

450

|

|

Max.Froce at electrodes(N)

|

6000

|

6000

|

10000

|

10000

|

10000

|

12000

|

12000

|

|

Working stroke(MM)

|

20

|

20

|

30

|

40

|

40

|

50

|

50

|

|

Cooling Water Consumpion 2.5bar(L/min)

|

6

|

6

|

8

|

8

|

8

|

10

|

10

|

|

Electrodes tip(MM

)

|

Φ13*45

|

Φ13*45

|

Φ16*45

|

Φ16*45

|

Φ16*45

|

Φ20*45

|

Φ20*45

|

|

Arms(MM)

|

Φ50*150

|

Φ50*150

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

Φ80*220

|

|

Projection Clamping Plate(MM)

|

125*125

|

125*125

|

200*200

|

200*200

|

200*200

|

200*200

|

200*200

|

|

Max.Welding

Capaciry A3 steel(MM) |

2.5+2.5

|

3+3

|

4+4

|

4.5+4.5

|

5+5

|

5+5

|

6+6

|

Main Features

1.The cnc rebar wire mech welding machine can weld more wlding points with more welding headseach time, and then automatically advances to the next row of welding points until all welding points are completed. The entire process is fully automatic controlled by PLC, equipped with monitoring and alarm.

2.The multi head spot welding machine uses direct power supply from a welding transformer to the workpiece, and regularly replaces the welding head, while also having energy-saving effects.

3. The rebar mesh welding machine adopts a pneumatic electrode that automatically adjusts the pre tightening force, with a relatively constant pre pressure. Compared to spring pre pressing, it has the characteristics of less electrode impact, less electrode wear, and more secure welding points. The spatter during the welding process is further reduced, and the electrode life is further extended.

4. The key electrical components of this product are controlled by PLC, and intelligent management is implemented for equipment operation. The touch screen operation makes the operation more convenient and concise.

Detail Images

More details,

please contact!

Hot Searches