- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Dming

-

Voltage:

-

3 phase 380V50Hz

-

Power:

-

8Kw

-

Weight (KG):

-

10000

Quick Details

-

Place of Origin:

-

China

-

Machine Type:

-

Casting machine

-

Marketing Type:

-

Hot Product 2023

-

Brand Name:

-

Dming

-

Voltage:

-

3 phase 380V50Hz

-

Power:

-

8Kw

-

Weight (KG):

-

10000

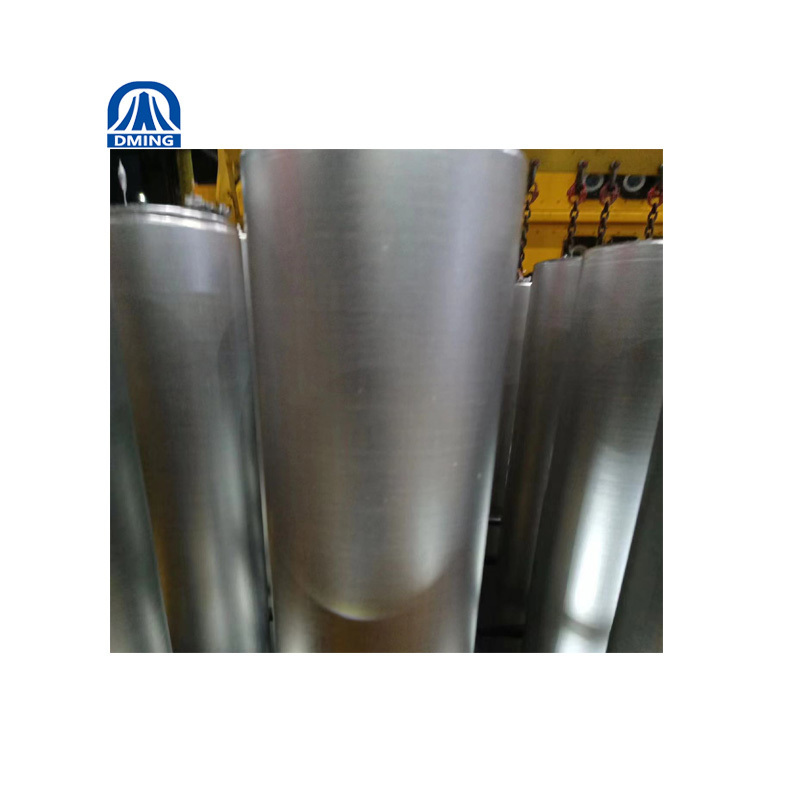

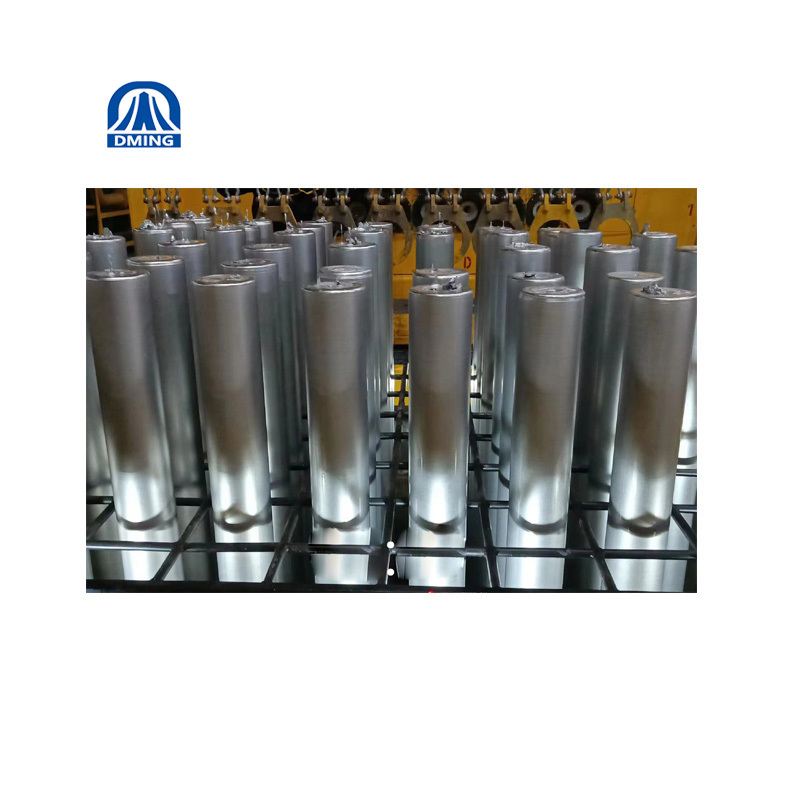

6 inch 7 inch 8 inch 9 inch 10 inch Dming 6 meters hot top casting machine Aluminum billet casting machine

The melted molten aluminum is cast into suitable high, medium and low-grade aluminum alloy ingots according to the type of alloy, shape and specification of the ingot, and appropriate process parameters.

The wire rope type casting winch system is a wire rope type without guide rails; the lowering and lifting of the casting platform adopts the winch to drive the wire rope operation, and the weight of the casting platform and the pouring aluminum liquid is used to lower; the lowering and lifting of the casting machine adopts the motor-driven worm gear reducer, worm gear The combination of the reducer drives the reducer and the reducer drives the reel; the speed regulation adopts frequency conversion speed regulation, and the casting speed regulation range is 30~250mm/min; the digital display of the up and down walking speed of the dummy platform, the casting length (the casting length adopts the rotary encoder pulse Induction signal, can accurately ensure the error), the cooling water inlet temperature, after the empty car rises to the limit, it automatically makes a safety stop, and can only be moved to the casting height by jogging; using a single drum with four wire ropes, the wire rope diameter is Φ1 6 mm, casting The maximum force that the machine can withstand is ≥18 tons (when the water level is high); the hoist is equipped with a manual lowering device; the control electrical appliances of the hoist and the hydraulic system are concentrated in an electric cabinet; the lifting platform is welded into a rectangle by a rectangular tube. For placing the dummy platform, two sets of pulleys are installed on the platform near the middle of the four guide rails. The lifting action can be realized by wire ropes. Four guiding devices are fixed at the four corners of the platform to ensure the vertical and parallelism between the top of the platform and the dummy head. . The steel structure and important parts in contact with water are treated with special anti-corrosion treatment to ensure the normal service life of the casting system for more than 10 years.

The wellhead frame is installed on the casting well, and the material of the wellhead frame is composed of rectangular pipes; the four main pulleys of the winch are installed in the wellhead frame; the tilting seat and the tilting arm are installed on the wellhead frame; the water inlet interface is installed beside the tilting arm, and the size of the water inlet interface is It is 6 inches; the tilting mechanism is operated by the hydraulic system, using 68# anti-wear hydraulic oil, and the hydraulic oil is provided by the buyer; the hydraulic cylinder is the product of the company, the oil pump is the product of the HCHC company, and the main hydraulic valve is the product of the YUKEN company.

|

Name |

Parametrer |

|

Winch Loading Capacity |

≥ 6 tons (I ngot/ L ifting P latform/ D ummy S eat) |

|

Tipping Loading Capacity |

≤5 tons |

|

Tilt angle of T ilting P latform |

≤90° |

|

Derrick B earing C apacity |

≥ 6 tons |

|

Hoist S troke |

≥8500mm |

|

Casting S peed |

30-250mm/min ( A djustable) |

|

Casting S peed A ccuracy |

±1% |

|

Casting L ength C ontrol A ccuracy |

≤±5% |

|

Lifting P latform D eviation |

±5mm |

|

Lifting P latform R eset A ccuracy |

≤±5.0mm |

|

Lifting P latform L ifting S peed |

≥520mm/min(with L oad) |

|

Lifting P latform S teel S tructure |

Machining / Spindle Holder Positioning Device |

|

Ingot B ending |

N ational S tandard |

|

H ydraulic M edium W orking T emperature |

10-50℃ |

|

Hydraulic S tation M edium |

68# A nti- W ear H ydraulic O il |

|

Total E quipment P ower |

8K w |