- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

L *W *H = 1800 *800 *1200;

-

Weight:

-

1500 KG

-

product name:

-

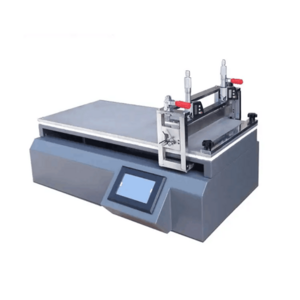

lab coating machine

-

transfering Speed::

-

1m/min continuously adjustable;

-

Furnace temperature::

-

room temperature ~ 150℃adjustable;

-

Electrode width::

-

≤ 300mm;

-

Coated precision::

-

≤ ±0.003mm

-

Retractable tension::

-

Adjustable

-

Current collector::

-

copper foil, aluminum foil, etc.

-

Power supply voltage::

-

380V/50HZ three-phase power supply;

-

Power consumption::

-

6.5KW;

-

Dimensions::

-

L *W *H = 1800 *800 *1200;

Quick Details

-

Voltage:

-

220V/110V

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

AME small automatic film coater

-

Dimension(L*W*H):

-

L *W *H = 1800 *800 *1200;

-

Weight:

-

1500 KG

-

product name:

-

lab coating machine

-

transfering Speed::

-

1m/min continuously adjustable;

-

Furnace temperature::

-

room temperature ~ 150℃adjustable;

-

Electrode width::

-

≤ 300mm;

-

Coated precision::

-

≤ ±0.003mm

-

Retractable tension::

-

Adjustable

-

Current collector::

-

copper foil, aluminum foil, etc.

-

Power supply voltage::

-

380V/50HZ three-phase power supply;

-

Power consumption::

-

6.5KW;

-

Dimensions::

-

L *W *H = 1800 *800 *1200;

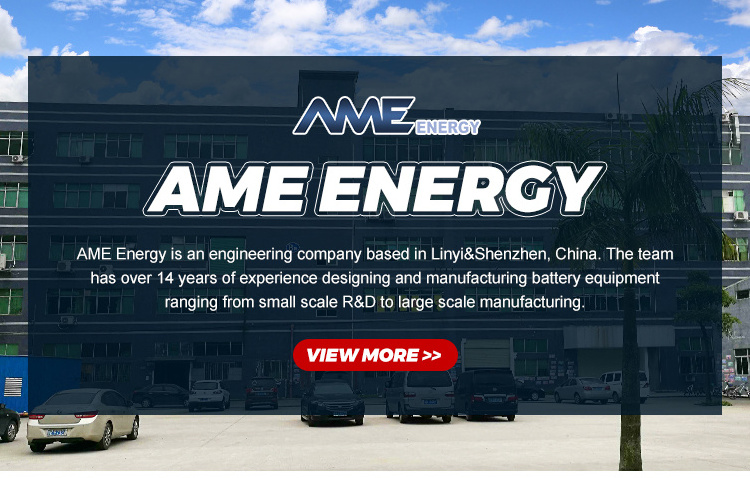

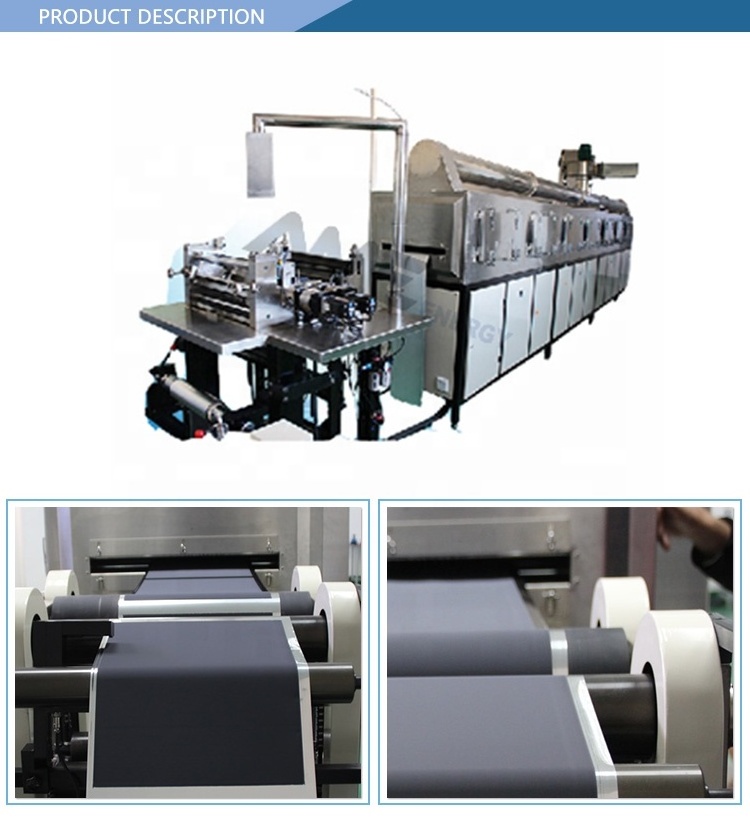

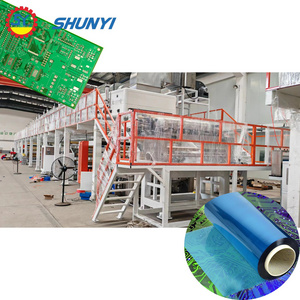

Automatic Film Coating Machine Extrusion For Film Roll Coating Machine For Lithium Battery Lab Research

|

Coating Method |

transferring intermittent/continuous coating |

|

Transfering Speed |

5~10m/min continuously adjustable |

|

Furnace Temperature |

150 degrees |

|

Electrode Width Coated |

≤500mm(Customized) |

|

Coated Precision |

≤±0.003mm |

|

Retractable Tension |

Adjustable |

|

Current Collector |

copper foil, aluminum foil, etc. |

|

Power Supply Voltage |

380V/50HZ three-phase power supply |

|

Power Consumption |

6.5KW |

|

Dimensions |

L *W *H = 1800 *800 *1200mm |

|

Total Machine Length |

≤25m |

|

Baking Oven Length |

18m(Customized) |

Automatic Roller Coating Li Polymer Battery Material Electrode Coating Machine With Drying Oven

Product Feature:

The coating machine is a compact Roll to Roll continuous coater is mainly used for lithium battery lab research and pilot scale production line.

Fast roll to roll coating system(0.5~5m/min) with

Drying Oven

for battery Electrode. It is integrated with the functions/features of metallic foil roll unwinding(reeling out),slurry feeder,coating blade,baking oven,and final electrode winding (reeling in) together

with touch screen operation

for customer's utmost convenience.

This lab coating machine is mainly used for

LFP, LCO, LMO and NCM

system battery cathode and anode electrode continuous coating.

We can also provide:

1.) A full set of lithium battery materials, including:

LiMn2O4, LTO, LiNiMnCoO2 (NMC), LiCoO2, graphite (MCMB) and other positive and negative battery materials; aluminum foil, copper foil, battery separator

, etc.

2.) A full set of lithium battery equipment, such as:

Mixer--coating machine--oven--rolling machine--welding machine--slitting/cutting machine--winding machine--sealing machine

, etc.