- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

like

-

Product item:

-

Flexible 36W Led Heatsink,Led Lamp Radiator Led 30W

-

Material:

-

AL1070

-

Process:

-

Cold Forging

-

Power:

-

30-45w,can be custom

-

Diameter:

-

102mm

-

Temper:

-

T3-T8

-

Thickness:

-

5-10mm

-

Color:

-

black,can be custom the color you want

-

Application:

-

Led Lighting Heat Sink

-

Keywords:

-

Large Aluminum Heat Sink For Power Amplifier

Quick Details

-

Shape:

-

Round

-

Body Material:

-

Aluminum

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

like

-

Product item:

-

Flexible 36W Led Heatsink,Led Lamp Radiator Led 30W

-

Material:

-

AL1070

-

Process:

-

Cold Forging

-

Power:

-

30-45w,can be custom

-

Diameter:

-

102mm

-

Temper:

-

T3-T8

-

Thickness:

-

5-10mm

-

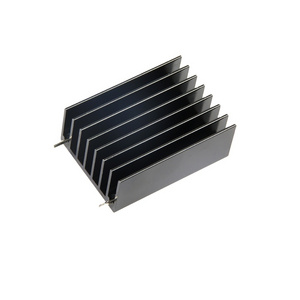

Color:

-

black,can be custom the color you want

-

Application:

-

Led Lighting Heat Sink

-

Keywords:

-

Large Aluminum Heat Sink For Power Amplifier

Hot Products

Product Details

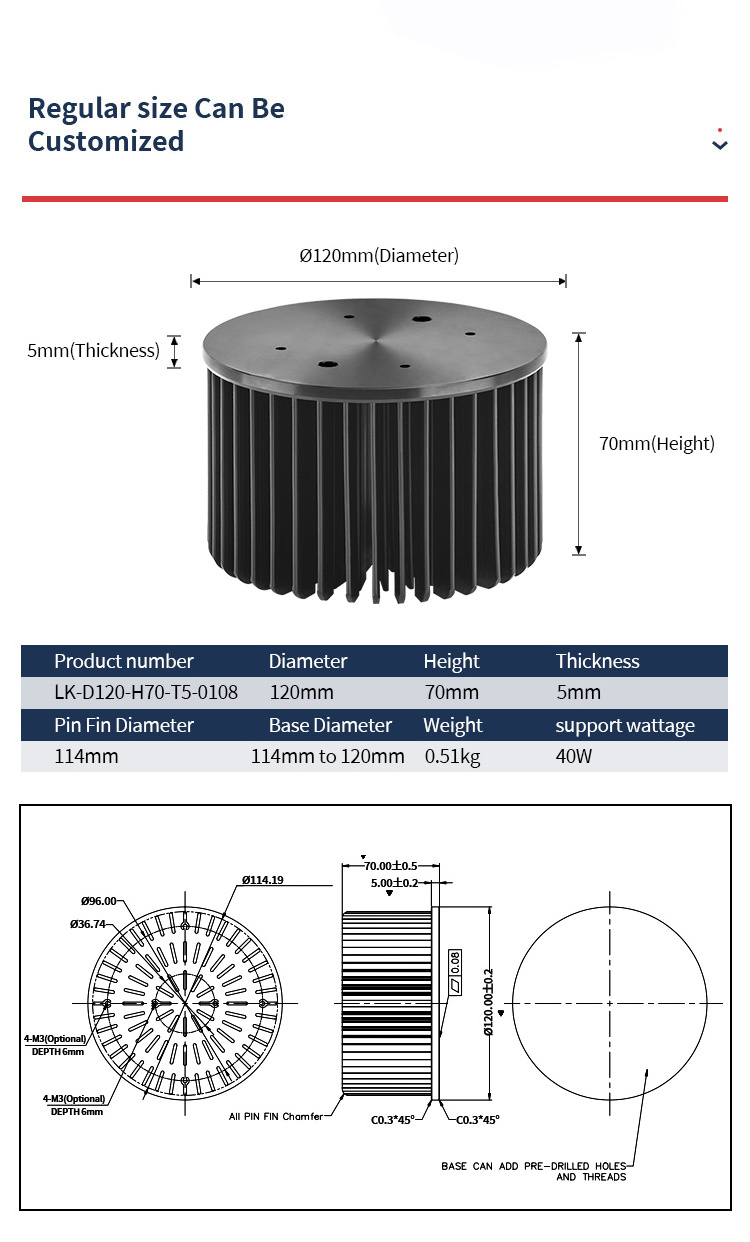

Shenzhen LIKE 30W Diameter 120mm Height 70mm Custom Heavy Duty Predrilled Cylindrical Aluminium Heatsink Heat Sink

Features:

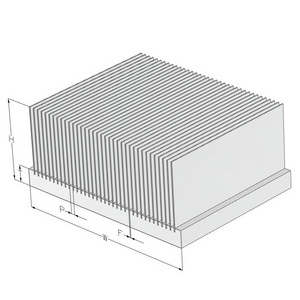

• Solid one-piece forged aluminum construction for maximum thermal conductivity.

• Pin fin design maximizes surface area and provides omni-directional cooling to eliminate concerns about orientation of the heat sink (unlike a linear extrusion).

•Precision-machined flat base ensures consistent contact between the heat sink, interface and LED substrate to maximize heat transfer.

• Standard 5mm base thickness allows for full recommended depth for mounting holes

•Precision-machined flat base ensures consistent contact between the heat sink, interface and LED substrate to maximize heat transfer.

• Standard 5mm base thickness allows for full recommended depth for mounting holes

Specification

|

product number

|

LK-D120-H40-T5-108

|

|

Diameter

|

120mm(7.724inch)

|

|

Height

|

70mm

|

|

Thickness

|

5mm(0.196inch)

|

|

Weigh

|

0.50kg

|

|

Power

|

30W

|

|

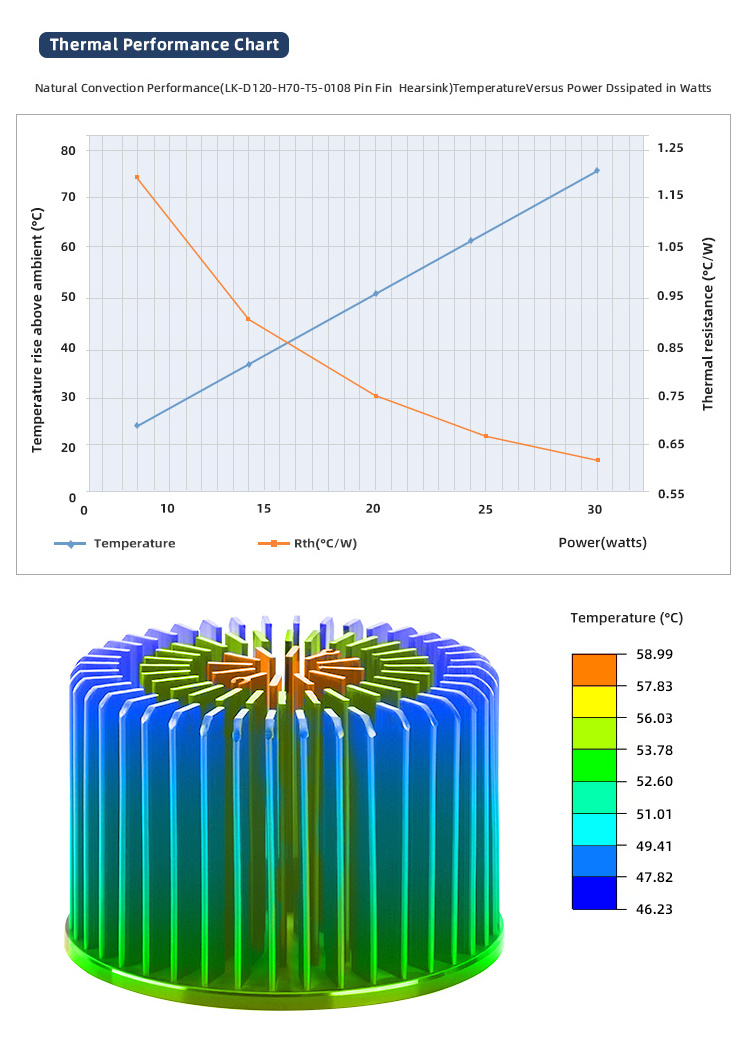

Thermal Resistance

|

0.59℃/W

|

|

Material

|

AL1070,AL1050

|

|

processing

|

Cold forging, CNC,Drilled, Threaded

|

|

Finish

|

Anodizing,electrophoresis

|

|

Color

|

Black,Silver,Any color, multi-color

|

|

Application

|

LED light,Track Lighting,high pole lights,high bay light

|

Details Images

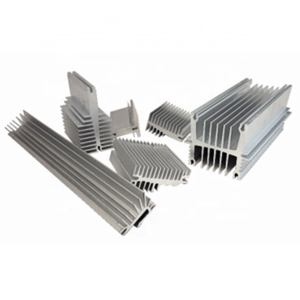

Why choose cold forging process:

Generally, heatsink has three processing processes: die casting, extrusion and cold forging. Because the material is different,the heat dissipation coefficient obtained is also different. Under the same size conditions, the power supported by cold forging heatsink is 2.35 times that of die casting and 1.45 times that of extruded profiles.

That is to say, when the user wants to get the same power, the cold forged heatsink will be smaller and lighter. The risk of hoisting is also reduced. Shipping costs are also lower.

Applications

Packing & Delivery

Hot Searches