- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

0.79 T

-

Power (kW):

-

400

-

Application:

-

Melting Aluminum

-

Product Name:

-

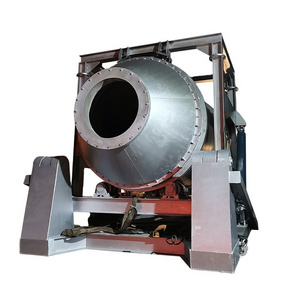

Induction Metal Melting Furnace

-

Melting Material:

-

Non-ferrous Metal

-

Max temperature:

-

1200.C

-

Final product:

-

Metal Ingot

-

Feature:

-

Energy-saving 30%

-

Melting Time:

-

90 Min

-

Input Voltage:

-

380V-3P

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Hong Teng

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

890*920*900mm

-

Weight (T):

-

0.79 T

-

Power (kW):

-

400

-

Application:

-

Melting Aluminum

-

Product Name:

-

Induction Metal Melting Furnace

-

Melting Material:

-

Non-ferrous Metal

-

Max temperature:

-

1200.C

-

Final product:

-

Metal Ingot

-

Feature:

-

Energy-saving 30%

-

Melting Time:

-

90 Min

-

Input Voltage:

-

380V-3P

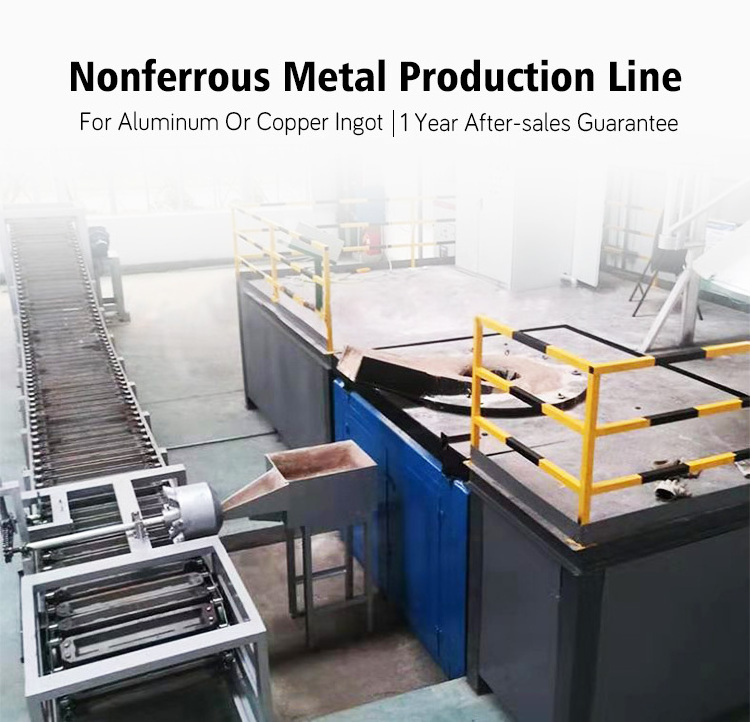

Oven to melt aluminum air fresheners for 200 kg aluminum making molds scrap electric cooking stove casting machine

Production details:

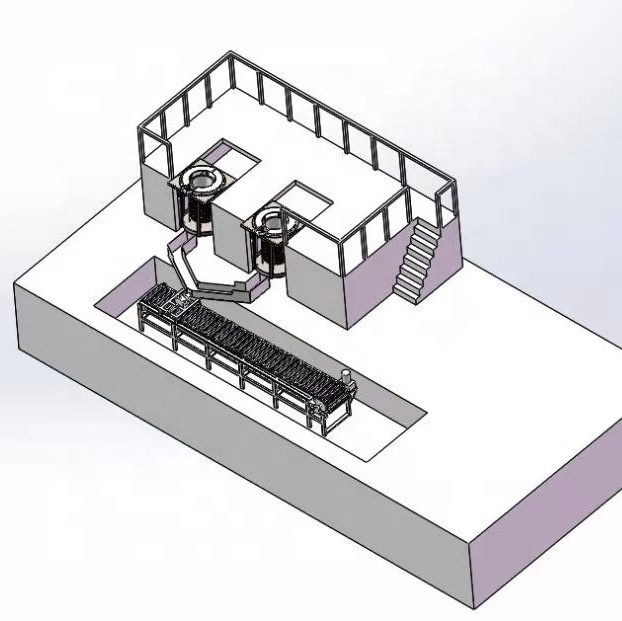

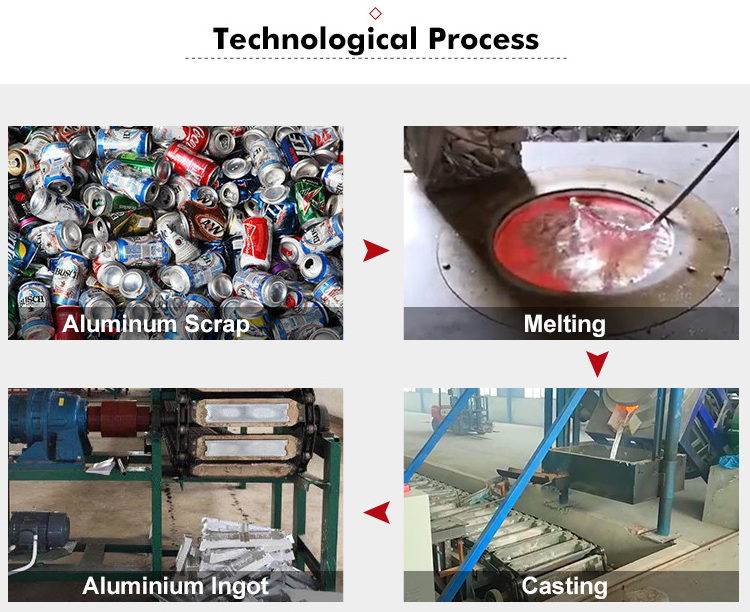

1).We supply turnkey project of aluminum ingots plant for customers.

2)Most raw material are waste aluminum cans for recycling to produce ingots.

3)Final products aluminum Ingots size: 10.0kg(ingots size can designed by customer)

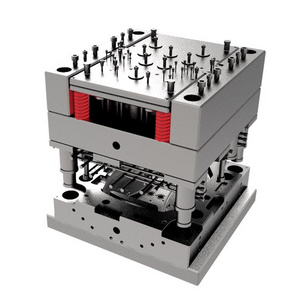

4)casting machine production capacity:Can produce 20pcs ingots per minute

5)casting machine main structure:

A.Using U-steel channel welded steel as casting machine body

B.Casting machine conveyor including speed-adjust motor, reducer, big & small chain wheel & chains, power distribution systems, ingots model weight 26-30kgs

2)Most raw material are waste aluminum cans for recycling to produce ingots.

3)Final products aluminum Ingots size: 10.0kg(ingots size can designed by customer)

4)casting machine production capacity:Can produce 20pcs ingots per minute

5)casting machine main structure:

A.Using U-steel channel welded steel as casting machine body

B.Casting machine conveyor including speed-adjust motor, reducer, big & small chain wheel & chains, power distribution systems, ingots model weight 26-30kgs

6).Reducer parameters:Ratio 473:1, spindle speed 0-2rev/min

7).Loading capacity 4KW-5.5KW

8).Aluminum ingots production line total length :18-24 meters

9).We will carefully confirm with customer’s requirement first, design machines under customer’s workshop size.Design drawing for customers to check.

10)We will send our engineers to customer’s factory to supply Installation & debugging service until machine start to normal production. We also supply training workers to operate machine and daily maintenance & repair service.

7).Loading capacity 4KW-5.5KW

8).Aluminum ingots production line total length :18-24 meters

9).We will carefully confirm with customer’s requirement first, design machines under customer’s workshop size.Design drawing for customers to check.

10)We will send our engineers to customer’s factory to supply Installation & debugging service until machine start to normal production. We also supply training workers to operate machine and daily maintenance & repair service.

Product Description

1, This equipment is aluminum ingot casting machine with high production efficiency. It can reach 10 Ton per hour

2, Ingots size: 6-30kg (ingots size can designed by customer)

3, The running speed of the equipment is 0-6 m/min adjustable

5, Aluminum ingots production line total length: 5-24 meters

2, Ingots size: 6-30kg (ingots size can designed by customer)

3, The running speed of the equipment is 0-6 m/min adjustable

5, Aluminum ingots production line total length: 5-24 meters

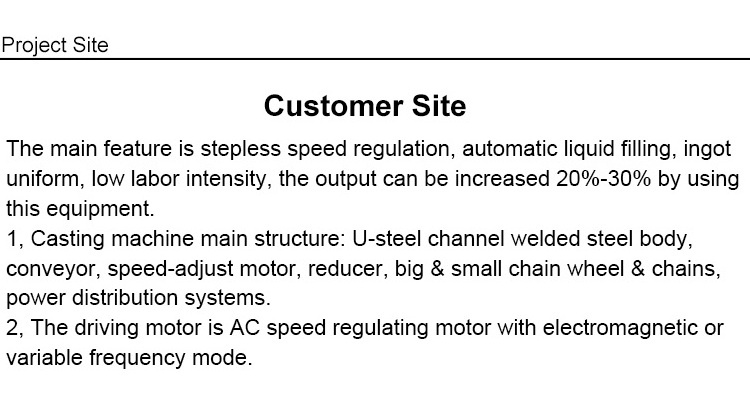

The main feature is stepless speed regulation, automatic liquid filling, ingot uniform, low labor intensity, the output can be increased 20%-30% by using this equipment

1, Casting machine main structure: U-steel channel welded steel body, conveyor, speed-adjust motor, reducer, big & small chain wheel & chains, power distribution systems

2, The driving motor is AC speed regulating motor with electromagnetic or variable frequency mode.

1, Casting machine main structure: U-steel channel welded steel body, conveyor, speed-adjust motor, reducer, big & small chain wheel & chains, power distribution systems

2, The driving motor is AC speed regulating motor with electromagnetic or variable frequency mode.

1, Provide overall solution and after-sales guarantee

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide overall equipment layout, aluminum ingots production line process design, electrical circuit layout.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

2, Provide plant design, proposal, manufacturing, shipping, installation and commissioning services

3, Provide overall equipment layout, aluminum ingots production line process design, electrical circuit layout.

4, Dispatch technicians to provide installation services after the machine arrives until the customer is satisfied

5, Long-term technical support, long-term machine warranty

|

Technical Parameter of induction melting furnace

|

|

|

|

|

||||

|

Model

|

MF power

|

Input voltage

|

MF Voltage

|

Frequency

|

||||

|

0.1T

|

80kw

|

3ph,380V

|

750V

|

2500HZ

|

||||

|

0.25T

|

180kw

|

3ph,380V

|

750V

|

2000HZ

|

||||

|

0.35T

|

200kw

|

3ph,380V

|

750V

|

1500HZ

|

||||

|

0.5T

|

400kw

|

3ph,380V

|

1500V

|

1500HZ

|

||||

|

0.75T

|

600kw

|

3ph,380V

|

1500V

|

1000HZ

|

||||

|

1T

|

700kw

|

3ph,660V

|

2400V

|

800HZ

|

||||

|

1.5T

|

800kw

|

3ph,660V

|

2500V

|

600HZ

|

||||

|

2T

|

1000kw

|

3ph,660V

|

2500V

|

600HZ

|

||||

Recommend Products

Customer site

Why Choose Us

Certifications

Hot Searches