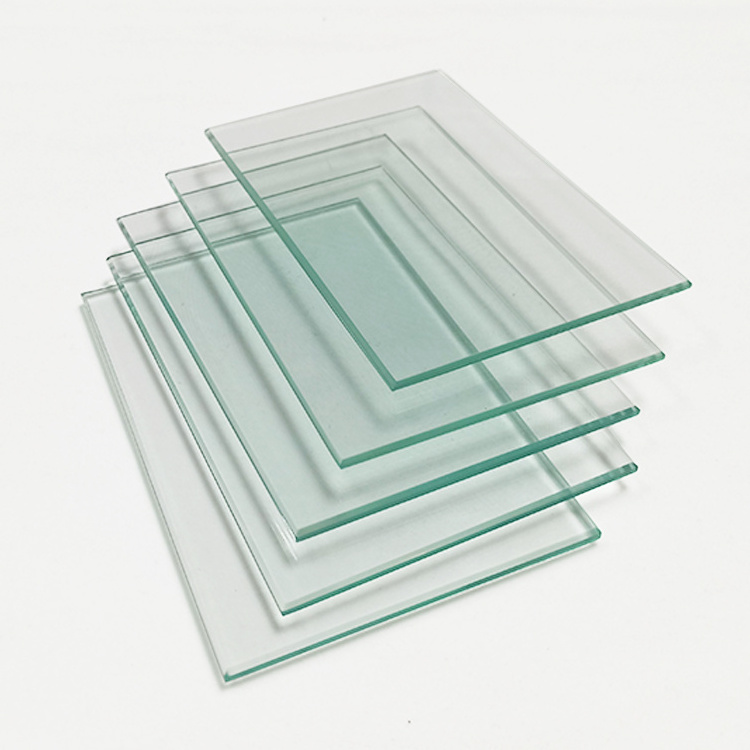

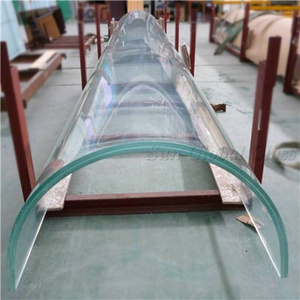

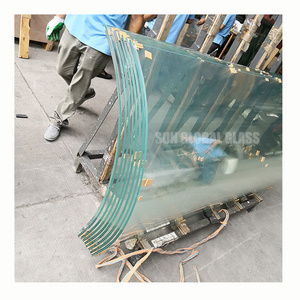

CE Certified flat curved safety custom tempered glass high quality construction toughened glass price per square foot

FOB Reference Price:

Get Latest Price

≥50 Square meters

US $29.9

≥1000 Square meters

US $19.9

≥5000 Square meters

US $10.9

≥10000 Square meters

US $5.5

Free Inquiry

Customized Request

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sun Global Glass

-

Model Number:

-

Custom tempered glass

-

Product name:

-

Tempered glass

-

color:

-

Clear, ultra clear, bronze, blue, green, grey, black, etc.

-

Processing:

-

Cut to size, polish edges, drill holes, safety corners etc.

-

Quality:

-

No bubble, no scratch, high precision flatness

-

Size:

-

Depends on your demand

-

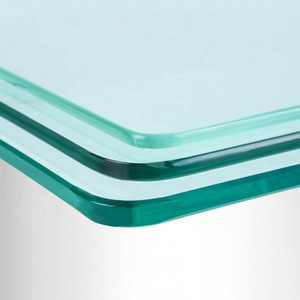

Edge:

-

Flat polished edge, pencil edge, beveled edge, ogee edge, matt edge,

-

Glass type:

-

Building float glass

-

Characteristic:

-

Up to five times stronger than annealed glass of the same thickness,

Quick Details

-

Application:

-

Hotel, Villa, Apartment, Office Building, Hospital, School, Mall, Sports Venues, Leisure Facilities, Supermarket, Warehouse, Workshop, Park, Farmhouse, Courtyard

-

Usage:

-

Industrial, Medical, Decoration, Solar, Greenhouse, Curtain Wall, Balustrades & Handrails, Image formation, Lighting, Bulletproof, Display screen, Instrument, Building

-

Thickness:

-

1mm-19mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sun Global Glass

-

Model Number:

-

Custom tempered glass

-

Product name:

-

Tempered glass

-

color:

-

Clear, ultra clear, bronze, blue, green, grey, black, etc.

-

Processing:

-

Cut to size, polish edges, drill holes, safety corners etc.

-

Quality:

-

No bubble, no scratch, high precision flatness

-

Size:

-

Depends on your demand

-

Edge:

-

Flat polished edge, pencil edge, beveled edge, ogee edge, matt edge,

-

Glass type:

-

Building float glass

-

Characteristic:

-

Up to five times stronger than annealed glass of the same thickness,

Product Description

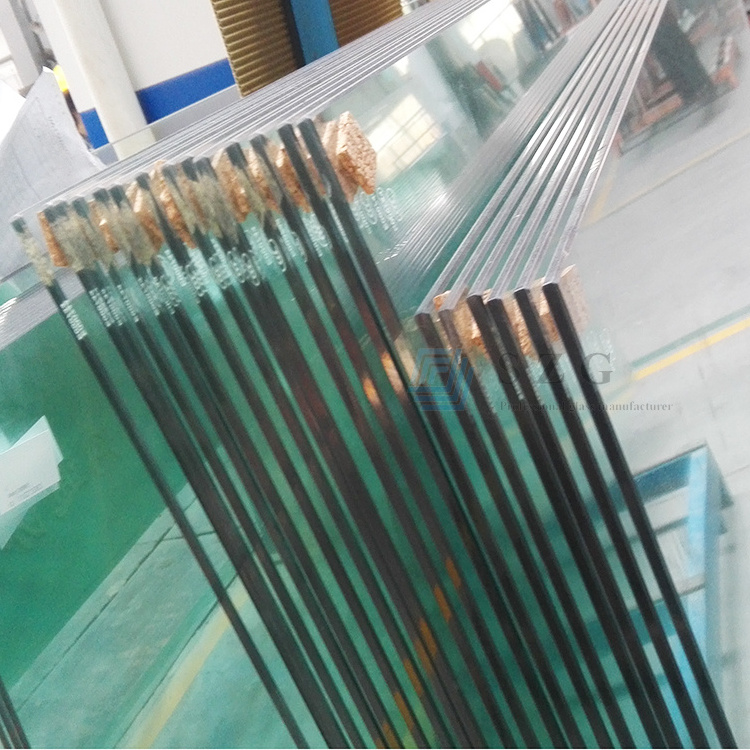

Clear tempered glass is fabricated by heating annealed glass to over 600°C and cooling it rapidly, which locks the outer surfaces of the glass in a state of high compression, and the core or center of the glass in compensating tension. It is a safety glass that has increased strength and will usually shatter in small cubical fragments when broken. It is used when strength, thermal resistance and safety are important considerations.

Types of tempered glass

Full tempered glass

Heat strengthened tempered glass

heat soaked tempered glass

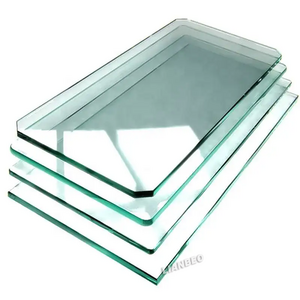

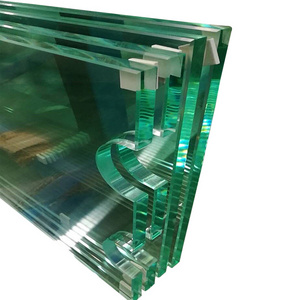

Specification of tempered glass

|

Thickness

|

3mm 4mm 5mm 6mm 8mm 10mm 12mm 15mm 19mm

(1/8'', 3/16'', 1/4'', 5/16'', 3/8'', 1/2'', 5/8'', 3/4'') |

|

|

|

|||

|

Available size

|

Flat shape max size is 3300*13000mm (over 15mm), Min size is 150*300mm

|

|

|

|

|||

|

Available color

|

Clear, ultra clear, blue, green, bronze, grey etc. Custom

|

|

|

|

|||

|

Quality

|

Grade A with CE certification and SGCC certification

|

|

|

|

|||

|

Characteristic

|

High safety, easy to clear and maintain, decorative

|

|

|

|

|||

|

Delivery time

|

Within 15 production time, shipping time should be confirm

|

|

|

|

|||

|

Glass type

|

Clear custom tempered glass, ultra clear custom tempered glass, frost custom tempered glass, patterned custom tempered glass, colored custom tempered glass, silk screen custom tempered glass etc.

|

|

|

|

|||

Characteristic of custom tempered glass

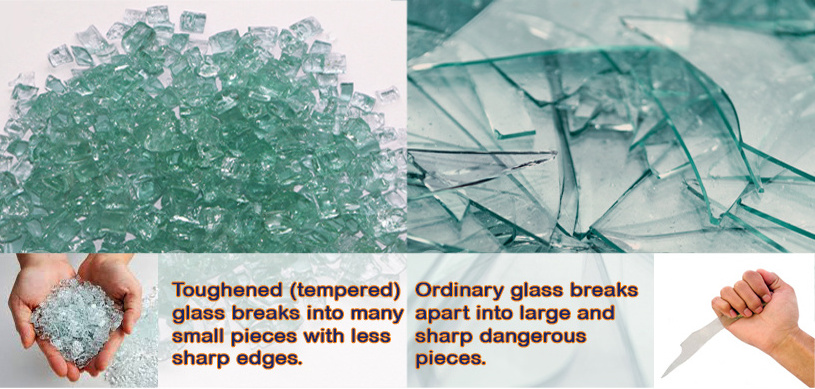

High stenghened: It's five times stronger than the non tempere glass of same thickness.

High safety: when toughened glass sheet is broken, it will become small particles and will not do harm for human being. Using toughened glass, it's more easy to clear and maintain.

High stenghened: It's five times stronger than the non tempere glass of same thickness.

High safety: when toughened glass sheet is broken, it will become small particles and will not do harm for human being. Using toughened glass, it's more easy to clear and maintain.

What is tempered glass self-explosion rate?

Automatic cracking of toughened glass under the action of no direct mechanical force is called the self explosion of toughened glass. According to industry experience, the self-explosion rate of ordinary toughened glass is about 1~3‰.Self - explosion is one of the inherent properties of toughened glass. There are several main factors

1. The influence of glass quality defect

2. Glass contains nickel sulfide crystals

3. The stress distribution in toughened glass is uneven and offset

How to deal with tempered glass self-explosion rate?

1. Reduced stress value of Toughened glass when production.

2. Uniform stress: Use high quality float glass or ultra clear glass for uniform stress.

3. Use low iron float glass as tempered material, the explosion rate reach 0.

4. Heat Soak Test: the best way and reduce self destruction rate thoroughly.

Automatic cracking of toughened glass under the action of no direct mechanical force is called the self explosion of toughened glass. According to industry experience, the self-explosion rate of ordinary toughened glass is about 1~3‰.Self - explosion is one of the inherent properties of toughened glass. There are several main factors

1. The influence of glass quality defect

2. Glass contains nickel sulfide crystals

3. The stress distribution in toughened glass is uneven and offset

How to deal with tempered glass self-explosion rate?

1. Reduced stress value of Toughened glass when production.

2. Uniform stress: Use high quality float glass or ultra clear glass for uniform stress.

3. Use low iron float glass as tempered material, the explosion rate reach 0.

4. Heat Soak Test: the best way and reduce self destruction rate thoroughly.

Applications

Windoe, door

Railing, blaustrade, fence,

handrail

Partition wall

Shower enclose, bathroom

Canopy,

ceiling, roof

Greenhouse, sunroom

Furniture, table top,

shelf

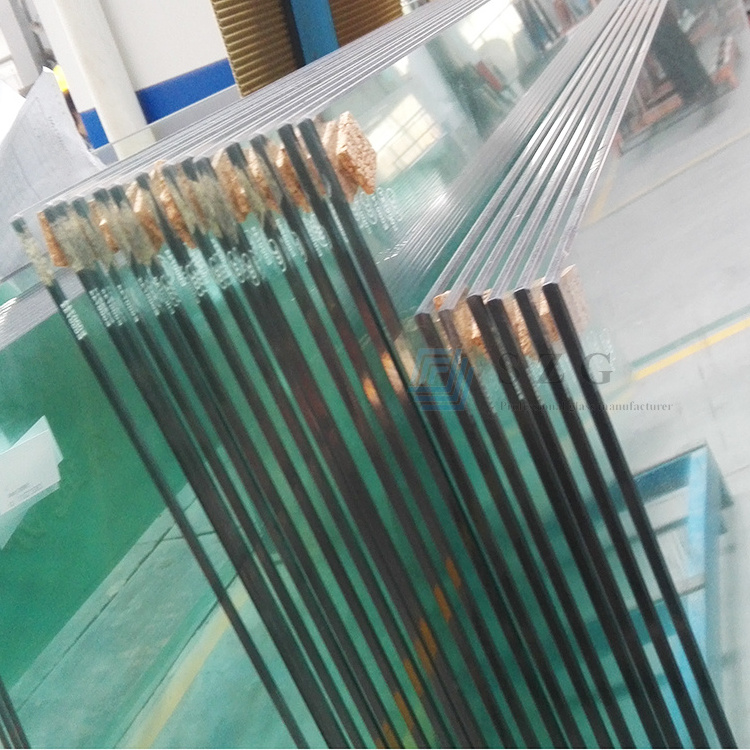

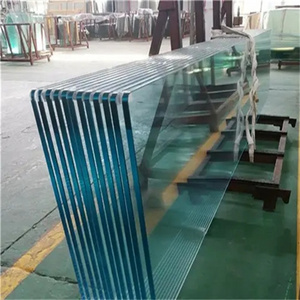

Advantages

Why choose our tempered glass

1. Quality control raw materials for tempering.

2. Excellent tempered glass production.

3. Very strict inspection for each glass.

4. Excellent strong plywood packages.

1. Quality control raw materials for tempering.

2. Excellent tempered glass production.

3. Very strict inspection for each glass.

4. Excellent strong plywood packages.

Customers come to factory for inspection

Processing Services

|

Dimension of holes

|

The minimum dimension of a hole should not be less than the thickness of the glass. The maximum dimension of the hole should not be more than 1/3 the narrowest dimension of the piece.

|

|

|

|

|

Notches and cutouts

|

All must have a fillet with radius equal to, or greater than the thickness of the glass.

|

|

|

|

|

Glass edge and hole

|

Glass less than 1/2" thick should not have holes located any closer than 1.5 times the thickness of the glass. Glass thicker than 1/2" should not have holes located any closer than 2 times the thickness of the glass.

|

|

|

|

|

Glass corner and hole

|

Holes should not be located any closer than 6.5 times the thickness of the glass.

|

|

|

|

Hot Searches