- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Dimensions(L*W*H):

-

1800mm*1380mm*1300mm

-

Weight:

-

650 KG

-

Certification:

-

CE

-

Max. Print Area:

-

800mm*1200mm

Quick Details

-

Condition:

-

New

-

Color & Page:

-

Multicolor

-

Voltage:

-

380v

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

ROYAL PACKING

-

Dimensions(L*W*H):

-

1800mm*1380mm*1300mm

-

Weight:

-

650 KG

-

Certification:

-

CE

-

Max. Print Area:

-

800mm*1200mm

Product Description

* Overview

The machine is economical and universal; With beautiful modeling of four corners of the manufacturing process for circular arc(change the traditional square tube right Angle welding), convenient and flexible operating system and high-speed and stable

printing and reasonable price advantages, widely favored by users;Products are widely used in hard items, plastic leather, non-woven bags, film switches, self-adhesive, process porcelain paper, heat transfer printing, watermarking, security and scratch card printing, card, gift box, wine box, desk calendar calendar, books

and other surface local UV, ice, wrinkles, refraction, scrub and other printing and scraping glue on the flat substrates.

printing and reasonable price advantages, widely favored by users;Products are widely used in hard items, plastic leather, non-woven bags, film switches, self-adhesive, process porcelain paper, heat transfer printing, watermarking, security and scratch card printing, card, gift box, wine box, desk calendar calendar, books

and other surface local UV, ice, wrinkles, refraction, scrub and other printing and scraping glue on the flat substrates.

* Features and functions:

1. the machine is double frequency control (swing arm and printing) motor synchronous belt drive, frequency control speed,stable operation.

2. multifunctional LCD computer version, control the whole operating system, powerful, simple and convenient operation.

3. scraper pressure adjustment mode: self-locking four cylinder control printing scraper and ink knife, each cylinder can adjust the pressure.

4. The machine is equipped with multiple functions of double scraper, which can change the ink-returning knife into scraper, and then the front and back can be scratched.

5. the printing arm and after the screen frame clamping device for the split mode, the screen can swing independently,convenient printing manual plate positioning.

6. printing platform in each direction of flexible fine-tuning, easy to overprint version, accurate alignment.

7. The left side of the operation panel is the toolbox, which is convenient for single machine to save tools and use.

8. printing operation stop braking mode, pneumatic brake device, precise stop

9. this model adds the rear clamp plate for pneumatic locking device, convenient for the operator to load and unload the screen plate and the version, improve the machine grade and work efficiency.

2. multifunctional LCD computer version, control the whole operating system, powerful, simple and convenient operation.

3. scraper pressure adjustment mode: self-locking four cylinder control printing scraper and ink knife, each cylinder can adjust the pressure.

4. The machine is equipped with multiple functions of double scraper, which can change the ink-returning knife into scraper, and then the front and back can be scratched.

5. the printing arm and after the screen frame clamping device for the split mode, the screen can swing independently,convenient printing manual plate positioning.

6. printing platform in each direction of flexible fine-tuning, easy to overprint version, accurate alignment.

7. The left side of the operation panel is the toolbox, which is convenient for single machine to save tools and use.

8. printing operation stop braking mode, pneumatic brake device, precise stop

9. this model adds the rear clamp plate for pneumatic locking device, convenient for the operator to load and unload the screen plate and the version, improve the machine grade and work efficiency.

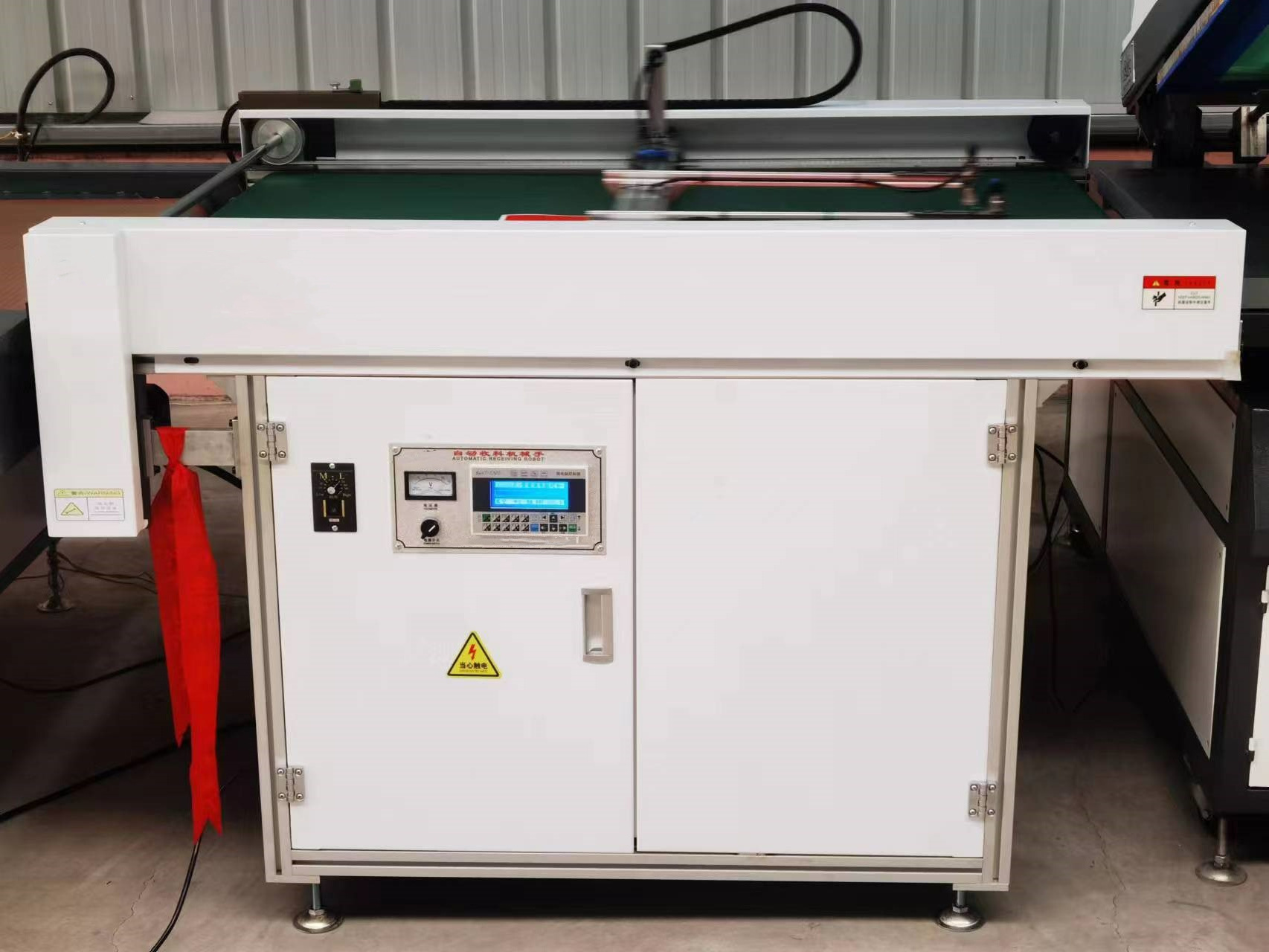

Characteristics:

This machine is designed for the combination of various kinds of screen printing equipment and various kinds of drying production line connection, forming a set of 3/4 automatic screen printing production line series. Using this machine to optimize the degree of automation of existing equipment is to save the cost of reducing labor and facilitate the use of operators, improve the production capacity of enterprises and save economic benefits. Suitable for all kinds of automatic screen printing, such as local UV, sugar tobacco and wine box packaging, tag heat transfer, floral paper, applique and so on.

Function:

1). This machine is a series of automatic grasping paper manipulator supporting semi

automatic screen printing machine. It is to grasp the paper printed on the screen printing machine into the drying production line (UV UV fixing machine) to complete the entire printing requirements. Connecting the machine only needs one person to put paper operation.

2). The paper grabbing principle is vacuum suction nozzle type and fixture type respectively. Before ordering, the customer needs to explain in advance which kind of paper grabbing principle to use (usually default to suction nozzle type).

3) The machine adopts the programmable controller system, all kinds of parameters can be set to run, travel length and speed can be set by the user; The speed of working paper grab is synchronized with that of semi-automatic screen printing machine.

automatic screen printing machine. It is to grasp the paper printed on the screen printing machine into the drying production line (UV UV fixing machine) to complete the entire printing requirements. Connecting the machine only needs one person to put paper operation.

2). The paper grabbing principle is vacuum suction nozzle type and fixture type respectively. Before ordering, the customer needs to explain in advance which kind of paper grabbing principle to use (usually default to suction nozzle type).

3) The machine adopts the programmable controller system, all kinds of parameters can be set to run, travel length and speed can be set by the user; The speed of working paper grab is synchronized with that of semi-automatic screen printing machine.

Basic Configuration:

1. Built-in air storage tank

2, closed-loop high-speed stepper motor, linear guide high precision extension slider synchronous belt drive.

3, Pentium PLC numerical control programming operating system

2, closed-loop high-speed stepper motor, linear guide high precision extension slider synchronous belt drive.

3, Pentium PLC numerical control programming operating system

Basic characteristics:

This machine is suitable for curing and drying all kinds of printing UV ink. This machine is equipped with automatic and semi-automatic screen printing equipment printing UV special effects process; Such as local UV glazing, matte, refraction, wrinkles (need to add wrinkle headlamp) and other UV material light curing.

functional configuration:

1) system mode: electronic power supply UV lamp power stepless voltage regulation, according to UV ink specific drying regulation light power, save energy.

2) lampshade: The use of aluminum magnesium alloy mirror reflection special UV lamp profile lampshade.

3) tube function: UV start automatically monitor the use of the tube and timing, energy consumption, reasonable grasp the service life of UV loss.

4) cooling mode: UV light solid room high-power fan air exhaust heat, axial flow fan cooling lamp shade.

5) operation mode: The use of high temperature and friction resistance 4*4 double dimension Teflon conveyor belt, the channel under the adsorption mode, so that the paper through smoothly.

6) transmission mode: electronic stepless speed regulation, according to the production situation to adjust the transmission speed, manual correction and fine tuning.

7) Appearance technology: The appearance design of this machine is novel; By the whole plate cold rolling laser cutting bending, appearance spray paint, electroplating, phosphating.

2) lampshade: The use of aluminum magnesium alloy mirror reflection special UV lamp profile lampshade.

3) tube function: UV start automatically monitor the use of the tube and timing, energy consumption, reasonable grasp the service life of UV loss.

4) cooling mode: UV light solid room high-power fan air exhaust heat, axial flow fan cooling lamp shade.

5) operation mode: The use of high temperature and friction resistance 4*4 double dimension Teflon conveyor belt, the channel under the adsorption mode, so that the paper through smoothly.

6) transmission mode: electronic stepless speed regulation, according to the production situation to adjust the transmission speed, manual correction and fine tuning.

7) Appearance technology: The appearance design of this machine is novel; By the whole plate cold rolling laser cutting bending, appearance spray paint, electroplating, phosphating.

Machine Photos

Products Photos

Product packaging

Specification

|

item

|

value

|

|

Applicable Industries

|

Manufacturing Plant, Printing Shops, Other, paperboard factory, cardboard factory, corrugated paperboard factory

|

|

Showroom Location

|

None

|

|

Condition

|

New

|

|

Type

|

flexo printing machine

|

|

Place of Origin

|

China

|

|

Weight

|

800kg

|

|

Warranty

|

1 Year

|

|

Production Capacity

|

1200pcs/h

|

|

Key Selling Points

|

High-accuracy

|

|

Max. workable width

|

1200mm

|

|

Machinery Test Report

|

Provided

|

|

Video outgoing-inspection

|

Provided

|

|

Marketing Type

|

Ordinary Product

|

|

Warranty of core components

|

3 months

|

|

Core Components

|

Motor, Other, Bearing, Engine, PLC

|

|

PLC Brand

|

Omron, Siemens

|

|

|

|

FAQ

1. who are we?

We are based in Zhejiang, China, start from 2021,sell to Mid East(40.00%),South America(10.00%),South Asia(5.00%),Central America(5.00%),Western Europe(5.00%),North America(5.00%),Eastern Asia(5.00%),Oceania(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%),Northern Europe(3.00%),Domestic Market(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Corrugated Paperboard Production Line,Single Facer Line,Flexo Printing Machine,Folder Gluer Machine,Flute Laminating Machine

4. why should you buy from us not from other suppliers?

We have our own factory in China. We have high quality employee team, special engineers, and special operators for export work of machines.And we have our Sales branch In Amman city, Jordan.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,German,Arabic,Russian

We are based in Zhejiang, China, start from 2021,sell to Mid East(40.00%),South America(10.00%),South Asia(5.00%),Central America(5.00%),Western Europe(5.00%),North America(5.00%),Eastern Asia(5.00%),Oceania(5.00%),Africa(5.00%),Southeast Asia(5.00%),Eastern Europe(5.00%),Northern Europe(3.00%),Domestic Market(1.00%),Southern Europe(1.00%). There are total about 11-50 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Corrugated Paperboard Production Line,Single Facer Line,Flexo Printing Machine,Folder Gluer Machine,Flute Laminating Machine

4. why should you buy from us not from other suppliers?

We have our own factory in China. We have high quality employee team, special engineers, and special operators for export work of machines.And we have our Sales branch In Amman city, Jordan.

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,CIP,FCA,CPT;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,German,Arabic,Russian

Hot Searches