- Product Details

- {{item.text}}

Quick Details

-

Frequency:

-

30-100KHZ

-

Package:

-

plywood case

-

Application:

-

Brazing, Melting, Quenching, Annealing etc.

-

Dimension:

-

500*210*460mm

-

Net weight:

-

21KG

-

H.S code:

-

8514400090

-

After-sales Service Provided:

-

Free spare parts

-

Name:

-

Low Price Portable Weld Machine Brazing Induction Equipment

-

Keyword:

-

Low Price Portable Weld Machine Brazing Induction Equipment

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Dongguan JINLAI

-

Weight (KG):

-

23

-

Frequency:

-

30-100KHZ

-

Package:

-

plywood case

-

Application:

-

Brazing, Melting, Quenching, Annealing etc.

-

Dimension:

-

500*210*460mm

-

Net weight:

-

21KG

-

H.S code:

-

8514400090

-

After-sales Service Provided:

-

Free spare parts

-

Name:

-

Low Price Portable Weld Machine Brazing Induction Equipment

-

Keyword:

-

Low Price Portable Weld Machine Brazing Induction Equipment

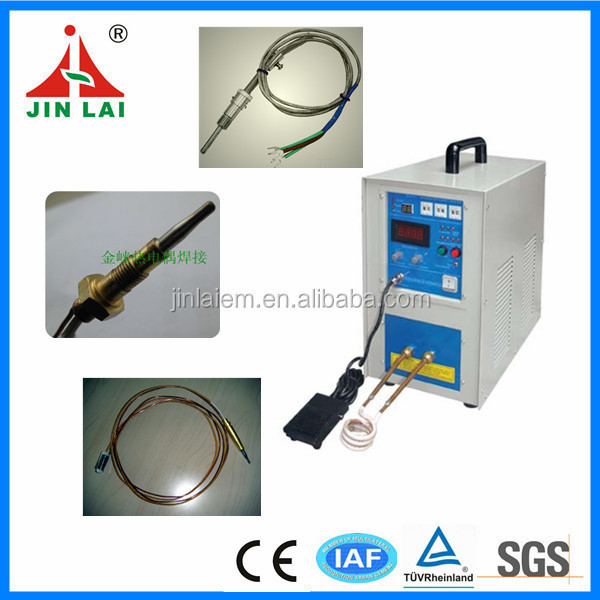

Low Price Portable Weld Machine Brazing Induction Equipment for Soldering Thermocouple (JL-15)

Low Price Portable Weld Machine Brazing Induction Equipment for Soldering Thermocouple (JL-15)

Main Characteristics:

- 1. Adoping MOSFGT and IGBT inverting device, tracking frequency automatically.

- 2. High frequency, heated quickly, its power consumption is only 20%~30% of eletronic tube induction heating machine and other heating style.

- 3. Security and reliability, the equipments have the secure voltage and it's secure to operate.

- 4. Manual, automatic regulating automatically, it can protect itself from over voltage, over current, lack of water, phase fail, over hot, etc.

- 5. It has no open-fire, noise and pollution, be suit for the environmental protection and fire, improve the image of the company.

- 6. Recommend usage: Weld, forging, hot cooperate, melting, quenching, anneat etc.

|

Model |

JL-15KW |

|

Input power desire |

Single phase 220V 50HZ |

|

Oscillate power max |

15KW |

|

Max input current |

37A |

|

Oscillate frequency |

30-100KHZ |

|

Cooling water desire |

>0.2MPa 2-6L/Min |

|

Duty cycle |

80% 40°C |

|

Dimensions(L*W*H) |

500*380*520mm |

|

Net weight |

32kg |

|

Cable length |

2-6(Meters) |

The principle of high frequency induction heating is that apply high frequency alernating current to a conduct that is curled to cyclic (normally copper tube) to produce flux, then put the metal to this area to make the flux to run through it, and eddy current will be generated in the deriction of self-capturing with flux(rotary current), the induced current then generates heat under the influence of the eddy current, so this heating method is called induction heating. hence, metal and other objects under heated can be heated without contact. at this moment, the character of the eddy current relies in that the induction heating on the object nearby the coil is outwardly strong but inwardly weak. with this principle. this heating body can be concentratedly heated where needed to achieve instantly effect, thereby the production output and work capacity are both improved.

The principle of high frequency induction heating is that apply high frequency alernating current to a conduct that is curled to cyclic (normally copper tube) to produce flux, then put the metal to this area to make the flux to run through it, and eddy current will be generated in the deriction of self-capturing with flux(rotary current), the induced current then generates heat under the influence of the eddy current, so this heating method is called induction heating. hence, metal and other objects under heated can be heated without contact. at this moment, the character of the eddy current relies in that the induction heating on the object nearby the coil is outwardly strong but inwardly weak. with this principle. this heating body can be concentratedly heated where needed to achieve instantly effect, thereby the production output and work capacity are both improved.

JL -15 Induction Heating Machine:

JL-15 Face-plate:

Application: Induction Heating Machine for Brazing Welding Soldering Thermocouple

Applications:

- 1. Metal tube welding: such as copper tube, steel tube, and aluminum tube’s butt welding, plug welding and welding sets.

- 2. Alloy cutter welding: such as alloy turning, milling cutter, planer, saw blades, reamer, boring knife.

- 3. Carbide saw blade welding: diamond saw blade welding, marble saw blade welding,woodworking saw blade welding, cut grass piece of welding, cut aluminum welding,

- 4. Metal welding: such as: towel rack, soap nets, towel holder, auto-accessories,motor accessories, metal terminals, hardware pieces, electric heating tube parts and fasteners.

- 5. make machine according to customers' actual working situation.

Packing List:

|

Item |

Name of machine or parts |

Specification |

Amount |

|

1 |

JL -15 Induction heating machine |

- |

1 pc |

|

2 |

Foot pedal |

3 core |

1 pc |

|

3 |

Induction Coils |

- |

2 sets |

|

4 |

Instruction Manual |

- |

1 pc |

|

5 |

Product catalog |

- |

2 sets |