- Product Details

- {{item.text}}

Quick Details

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

30 mm

-

Dimension:

-

4500*2000*2700mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

AOXUANZG

-

Year:

-

new

-

Weight (KG):

-

15000

-

Motor Power (kw):

-

15 kw

-

Warranty of core components:

-

2 years

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Control system:

-

DA69T

-

Color:

-

Customizable

-

Material:

-

Metal Steel Sheet

-

Main Motor:

-

15kw

-

Voltage:

-

220V/380V/415V/440V/customized

-

Control Axis:

-

8+1 Axis

-

Worktable Length:

-

4000mm

-

Poles Distance:

-

3200mm

-

Dimensions:

-

4500*2000*2700mm

Quick Details

-

Machine Type:

-

Synchronized

-

Length of Working Table (mm):

-

4000

-

Slider Stroke (mm):

-

250 mm

-

Throat Depth (mm):

-

350 mm

-

Width of Working Table (mm):

-

30 mm

-

Dimension:

-

4500*2000*2700mm

-

Place of Origin:

-

Anhui, China

-

Brand Name:

-

AOXUANZG

-

Year:

-

new

-

Weight (KG):

-

15000

-

Motor Power (kw):

-

15 kw

-

Warranty of core components:

-

2 years

-

Product name:

-

Hydraulic Cnc Bending Machine

-

Control system:

-

DA69T

-

Color:

-

Customizable

-

Material:

-

Metal Steel Sheet

-

Main Motor:

-

15kw

-

Voltage:

-

220V/380V/415V/440V/customized

-

Control Axis:

-

8+1 Axis

-

Worktable Length:

-

4000mm

-

Poles Distance:

-

3200mm

-

Dimensions:

-

4500*2000*2700mm

Product Description

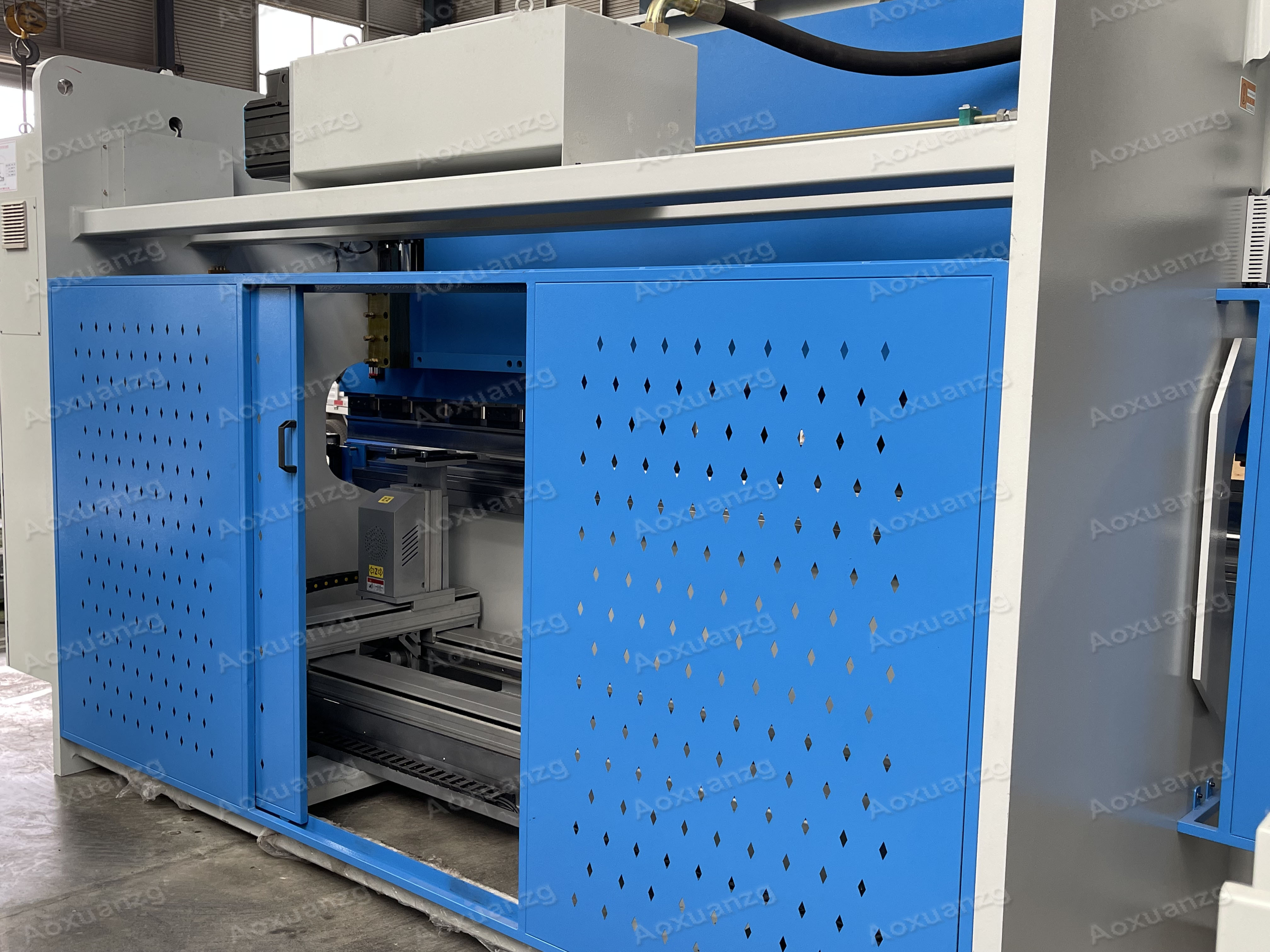

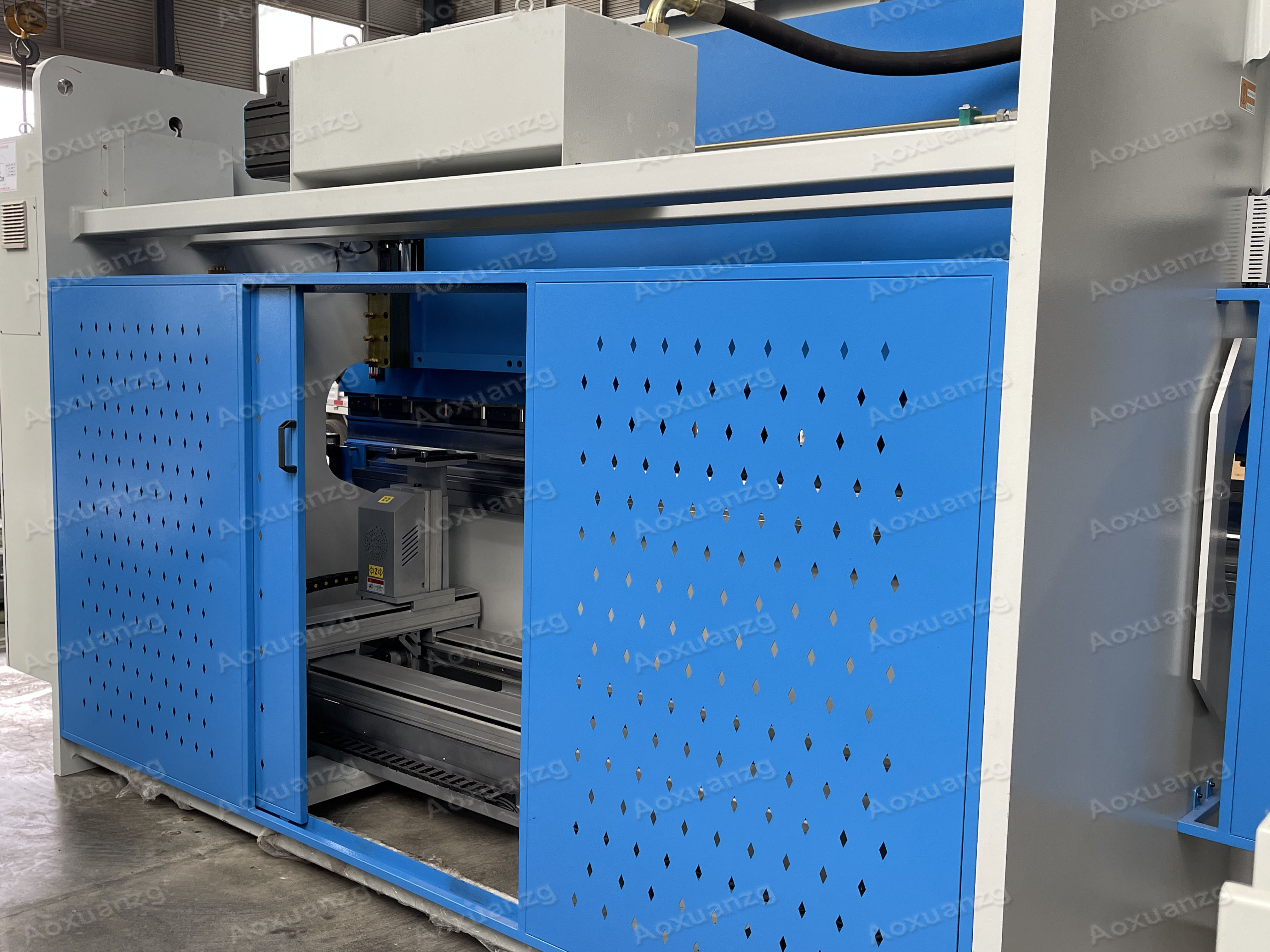

200T4000mm DA69T 8+1 Axis Hydraulic Bending Machine CNC Panel Bender Press Brake Sheet Metal Bending Machine

Product Application

Press brake is a kind of machine specially in bending plate, mainly used in automotive manufacturing, kitchen appliance manufacturing, electricity poles, lamp posts, ship-building, military industry, steel industry, mechanical manufacturing. Bending dies can be designed and changed according to customers’ different needs.

Main types of press brake produced by our company are: manual torsion, CNC torsion press brake, electro-hydraulic press brake, large electro-hydraulic synchronization press brake Currently, our biggest press brake equipment is 1000T/10000, production for many years, and stable performance.

Main Features:

1-Special numeric-control system is fitted with mainframe of the bending machine.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well prccedures and paremeters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

2-Multi-work-stop programming function is able to achieve an automatic operation and continues positing of multi-step procedures,

as well as an automatic precision adjustment for positions of rear stopper and gliding block.

3-The machine is provided with bend counting function, for a real-time display of processing quantity and power-failure memory of

positions of stopper and gliding block, as well prccedures and paremeters.

4-Imported ball bearing lead screw and linear guide rail are used for rear stopper, to ensure the positioning precision of rear

stopper, for processing precision of machine to be higher.

Main Configuration

|

No.

|

Parts Name

|

Brand

|

|

1

|

Main motor

|

Siemens,Germany

|

|

2

|

Electrics

|

Schneider,France

|

|

3

|

Hydraulic valve

|

Rexroth,Germany

|

|

4

|

Oil Pump

|

Sunny, U.S.A

|

|

5

|

Seal ring

|

NOK, Japan

|

|

6

|

Pipe connector

|

EMB, Germany

|

|

7

|

Controller

|

DA69T

|

|

8

|

Foot switch

|

Karcon, South Korea

|

|

9

|

Ball screw

|

HINWIN,Taiwan

|

|

10

|

Guide rail

|

HINWIN,Taiwan

|

Certificates

200T4000mm DA69T 8+1 Axis Hydraulic Bending Machine CNC Panel Bender Press Brake Sheet Metal Bending Machine

Packing & Delivery

Packing Detail:

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

☂ Each Hydraulic Bending Machine with plastic film package first, then placed in a wooden case, wooden case with a foam filling.

✈ We loaded the truck with heavy trucks for loading the cargo to the harbor terminal.At the dock we pack the goods in containers

and ship them abroad.

Delivery Detail :

☀ Shipped in 25 days after payment

Customer Reviews

Hot Searches