- Product Details

- {{item.text}}

Quick Details

-

Use:

-

Bag, Industry, Blanket, Shoes, Lining, Luggage, Accessories, Bags,Purses & Totes, craft, Outdoor, Car, Outdoor-Umbrella, Outdoor-Tent, Outdoor-Awning, Outdoor-Industry, Hospital, Toy

-

Weight:

-

50-200g/m2

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DSN

-

Model Number:

-

Prepreg carbon fiber fabric

-

Product Name:

-

Carbon Fiber Fabric

-

Weave:

-

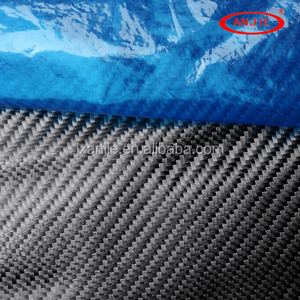

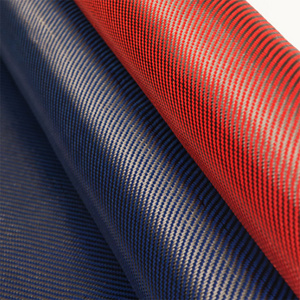

3K Twill/3K Plain

-

Materials:

-

Epoxy Resin+Carbon Cloth

-

Size:

-

Customized Size

-

Curing temperature:

-

150℃

-

Yarn Type:

-

3k 6k 12k 24K

-

Storage temperature:

-

< -18℃

-

Keywords:

-

Carbon Fiber Fabric

-

Application:

-

Electronics, sports product, automobile

-

Package:

-

Carton box

Quick Details

-

Pattern:

-

SOLIDS

-

Material:

-

100% Carbon Fiber

-

Feature:

-

Abrasion-Resistant, Waterproof, Anti-Static, Heat-Insulation, DIMENSIONAL, Double Faced, Sustainable, Water Resistant, Chemical-Resistant, Tear-Resistant

-

Use:

-

Bag, Industry, Blanket, Shoes, Lining, Luggage, Accessories, Bags,Purses & Totes, craft, Outdoor, Car, Outdoor-Umbrella, Outdoor-Tent, Outdoor-Awning, Outdoor-Industry, Hospital, Toy

-

Weight:

-

50-200g/m2

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DSN

-

Model Number:

-

Prepreg carbon fiber fabric

-

Product Name:

-

Carbon Fiber Fabric

-

Weave:

-

3K Twill/3K Plain

-

Materials:

-

Epoxy Resin+Carbon Cloth

-

Size:

-

Customized Size

-

Curing temperature:

-

150℃

-

Yarn Type:

-

3k 6k 12k 24K

-

Storage temperature:

-

< -18℃

-

Keywords:

-

Carbon Fiber Fabric

-

Application:

-

Electronics, sports product, automobile

-

Package:

-

Carton box

Product Description

A new composite material choice for the 21st century--Carbon Fiber

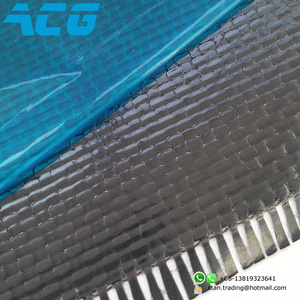

Carbon fiber prepreg can be divided into unidirectional prepreg and bidirectional woven prepreg according to the weaving method. It is a carbon fiber composite material made by processing epoxy resin and carbon fiber through processes such as hot melting, coating, hot pressing, cooling, laminating, and coiling. Carbon fiber prepreg is a semi-finished product of epoxy resin and carbon fiber that is initially impregnated but not cured. It can only be formed by heating and curing after being made into a product.

Feature

1. High strength, low density, light weight,strength can reach 6-12 times of steel, density is only one quarter of steel.

2. High fatigue strength.

3. High dimensional stability.

4. Excellent electrical and thermal conductivity.

5. Excellent vibration attenuation performance.

6. Excellent heat resistance.

7. The friction coefficient is small and the wear resistance is excellent.

8. Corrosion resistant and long life.

9. X-ray permeability is large.

10. Good plasticity, can be made into any shape according to the shape of the mold, easy to form and easy to process.

2. High fatigue strength.

3. High dimensional stability.

4. Excellent electrical and thermal conductivity.

5. Excellent vibration attenuation performance.

6. Excellent heat resistance.

7. The friction coefficient is small and the wear resistance is excellent.

8. Corrosion resistant and long life.

9. X-ray permeability is large.

10. Good plasticity, can be made into any shape according to the shape of the mold, easy to form and easy to process.

Specification

UD CARBON FIBER PREPREG

|

Item No.

|

FAW

(g/㎡)

|

RC(%)

|

Total weight

(g/㎡)

|

Thickness (mm)

|

Width

(mm)

|

Length

(m)

|

Thickness (mm)

|

|

DSN-45-0250

|

25

|

45

|

45.5

|

0.025

|

1000

|

150

|

24T/30T/40T T300/T700/T800

|

|

DSN-40-0300

|

30

|

40

|

50

|

0.03

|

1000

|

150

|

|

|

DSN-38-0500

|

50

|

38

|

80

|

0.06

|

1000

|

150

|

|

|

DSN-38-0750

|

75

|

38

|

121

|

0.08

|

1000

|

150

|

|

|

DSN-36-1000

|

100

|

36

|

156

|

0.10

|

1000

|

100

|

|

|

DSN-36-1250

|

125

|

36

|

195

|

0.13

|

1000

|

150

|

|

|

DSN-35-1500

|

150

|

35

|

231

|

0.15

|

1000

|

150

|

|

|

DSN-35-1750

|

175

|

35

|

269

|

0.18

|

1000

|

150

|

|

|

DSN-35-2000

|

200

|

35

|

308

|

0.20

|

1000

|

150

|

|

Remarks:

1.Resin content can be customized, tolerance: 土2%;

2.Fiber areal weight: 25-400g/m, can be customized;

3.The resin types are various, such as flame retardancy, low halogen, fast curing, and bio-based materials etc.

4.Storage conditions: recommended low temperature storage. lt can be kept for 6 months below -18°c, 3months at -5 ~0°C, and 15 days at room temperature (25°C).

CARBON FIBER FABRIC PREPREG

|

ltem No.

|

FAW

(g/㎡)

|

RC

(%)

|

Total weight

(g/㎡)

|

Fabric Type

|

Filament category

|

Fiber Origin

|

Width

(mm)

|

Length

(m)

|

|

DSN-1-40-120P

|

120

|

40

|

200

|

Plain

|

1K

|

China/Import

|

1000

|

100

|

|

DSN-1-40-120T

|

120

|

40

|

200

|

Twill

|

1K

|

China/Import

|

1000

|

100

|

|

DSN-3-40-200P

|

200

|

40

|

333

|

Plain

|

3K

|

China/Import

|

1000

|

100

|

|

DSN-3-40-200T

|

200

|

40

|

333

|

Twill

|

3K

|

China/Import

|

1000

|

100

|

|

DSN-3-40-240P

|

240

|

40

|

400

|

Plain

|

3K

|

China/Import

|

1000

|

100

|

|

DSN-3-40-240T

|

240

|

40

|

400

|

Twill

|

3K

|

China/Import

|

1000

|

100

|

|

DSN-6-40-280P

|

280

|

40

|

467

|

Plain

|

6K

|

China/Import

|

1000

|

100

|

|

DSN-6-40-280T

|

280

|

40

|

467

|

Twill

|

6K

|

China/Import

|

1000

|

100

|

|

DSN-12-40-400P

|

400

|

40

|

667

|

Plain

|

12K

|

China/Import

|

1000

|

100

|

|

DSN-12-40-400T

|

400

|

40

|

667

|

Twill

|

12K

|

China/Import

|

1000

|

100

|

Remarks:

1. Resin content can be customized, tolerance: 土2%;

2. The resin types are various, such as flame retardancy, low halogen, fast curing, and bio-based materials etc.

3. Storage conditions: recommended low temperature storage. lt can be kept for 6 months below -18°C , 3 months at -5~0°c,and 15 days at room temperature (25°C).

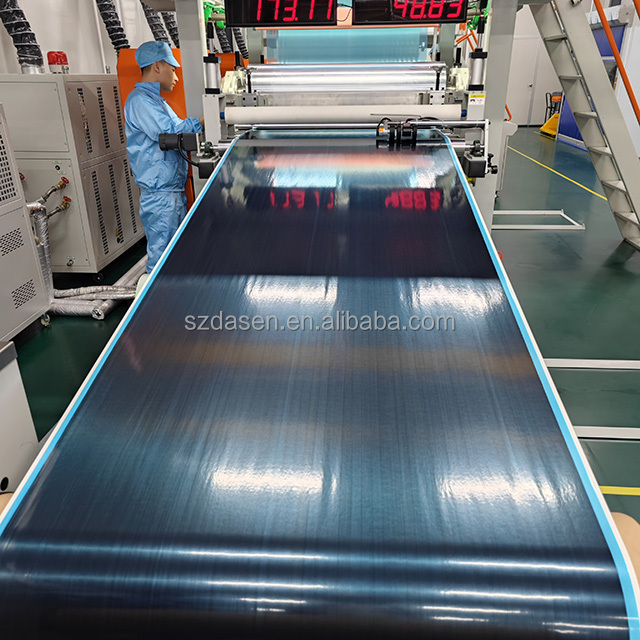

Production Line

Application

Carbon fiber tubes

Roll wrapped prepreg carbon fiber tubes are constructed using multiple wraps of twill and/or unidirectional fabrics. Rolled tubes are ideal for applications that require the highest bending stiffness and lowest weight, such as automation robotics, telescoping poles, idler rollers, and UAV components. The standard finish is cello-wrapped gloss, but a smooth sanded finish is also available.

Carbon fiber bicycle accessories

Carbon fiber bicycle has 5 advantages, so more and more bicycles use carbon fiber prepreg material

1 Light weight: effectively reduce the overall weight of the bike, cyclists can reduce the physical loss of riding, riding speed faster, riding distance farther.

2 Good rigidity: carbon fiber bicycle because of the excellent strength, rigidity, conducive to the transformation of the

driving force, improve the maneuverability of the whole bike, enhance the comfort of riding.

driving force, improve the maneuverability of the whole bike, enhance the comfort of riding.

3 Good shock resistance: The carbon fiber composite material comes with good damping, which can improve the shock resistance and provide cushioning for the ups and downs that occur during the ride, making the ride more comfortable.

4 High safety: carbon fiber bicycle has good impact resistance and will not be damaged in a general collision.

5 Good durability: Carbon fiber bicycle has good resistance to acid and alkali,corrosion, salt spray and oxidation, which prolongs the service life of the bicycle.

Carbon fiber insole/ liners

Many well-known sports shoe brands use carbon fiber insoles or liners in their shoes.

1 Reduce the weight of the shoe to make it lighter to wear . The carbon material is a lightweight material with good toughness and strength .

2 improve the elasticity of the shoe, which can make the sportsman react faster. The liner makes the shoes more highly elastic and can provide a thrust for the sportsman.

3 strenuous exercise carbon fiber insole or liner does not deform, can protect the feet of athletes from injury.

Other application

At present, civil carbon fiber prepreg has been widely used in:

1 Leisure sports: fishing rod, bow and arrow, kayak, ski, water ski, golf club, bicycle, dragon boat, kite skeleton, punching boat, lifeboat, etc.

2 competitive sports: bicycles, kayaks, diving boards, spreader bars, etc.

3 Life products: helmets, drone skins, masks, toys, luggage , etc.

4 Construction engineering:bridges, structural beams, building repair, gymnasium roof, etc.

5 Automobile manufacturing: bumpers, dashboards, baseboards, door frame versions, hoods, roof panels, air pressure tanks, etc.

6 Electronic Products: phone case, watch strap, laptop/pad bracket,CPU cooling fan, etc.

Packing & Delivery

Packed with plastic bag and cartons/pallets.

The prepreg requires storage at temperatures below -18℃.

Our factory support package, logo customization when more than 600 Square meters.

The prepreg requires storage at temperatures below -18℃.

Our factory support package, logo customization when more than 600 Square meters.

Related Products

FAQ

Q1. Can I have a sample order?

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7-10 days, mass production time needs 4 weeks If need a big quantity.

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 7 days to arrive.

Airline and sea shipping also optional,need to consult the freight forwarder by address/ port.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q5. Is it OK to print my logo on carton?

A: Yes. Please inform us formally before our production and confirm the design.

Q6: What is your terms of payment ?

A: Payment<=10000 USD , 100% in advance.

Payment>=10000 USD , 50% T/T in advance ,balance before shipping.

If you have another question, please feel free to contact us !

A: Yes, we welcome sample order to test and check quality.

Q2. What about the lead time?

A:Sample needs 7-10 days, mass production time needs 4 weeks If need a big quantity.

Q3. How do you ship the goods and how long does it take to arrive?

A: We usually ship by DHL, UPS, FedEx or TNT. It usually takes 7 days to arrive.

Airline and sea shipping also optional,need to consult the freight forwarder by address/ port.

Q4. How to proceed an order ?

A: Firstly let us know your requirements or application.

Secondly We quote according to your requirements or our suggestions.

Thirdly customer confirms the samples and places deposit for formal order.

Fourthly We arrange the production.

Q5. Is it OK to print my logo on carton?

A: Yes. Please inform us formally before our production and confirm the design.

Q6: What is your terms of payment ?

A: Payment<=10000 USD , 100% in advance.

Payment>=10000 USD , 50% T/T in advance ,balance before shipping.

If you have another question, please feel free to contact us !

Title goes here.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Hot Searches