- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

≥99%

-

Voltage:

-

380V/50Hz(Can be customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Chengxiang

-

Dimension(L*W*H):

-

2140*1060*1800mm

-

Weight:

-

350 KG

-

Touch screen (Optional):

-

Siemens

-

PLC:

-

Siemens

-

Inverter:

-

Mitsubishi

-

Main motor:

-

ABB

-

low-voltage apparatus:

-

Schneider

-

Qualified capping:

-

99%

-

Material:

-

316L+304 Stainless steel

Quick Details

-

Machinery Capacity:

-

4000BPH, 12000BPH

-

Packaging Material:

-

Metal, Glass, Wood

-

Filling Material:

-

Oil

-

Filling Accuracy:

-

≥99%

-

Voltage:

-

380V/50Hz(Can be customized)

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Chengxiang

-

Dimension(L*W*H):

-

2140*1060*1800mm

-

Weight:

-

350 KG

-

Touch screen (Optional):

-

Siemens

-

PLC:

-

Siemens

-

Inverter:

-

Mitsubishi

-

Main motor:

-

ABB

-

low-voltage apparatus:

-

Schneider

-

Qualified capping:

-

99%

-

Material:

-

316L+304 Stainless steel

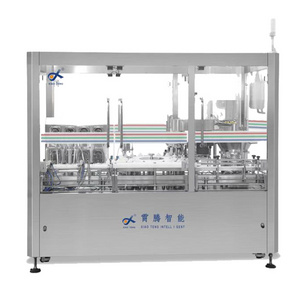

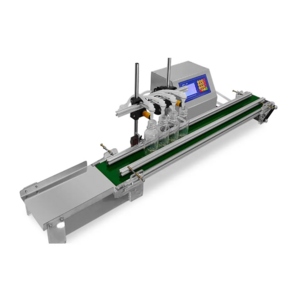

Model No:CX-GFT Syrup filling machine

This machine can be customized for different bottle size and pet,ROPP caps

Upgrade piston pump easy clean,connected with liquid parts are SUS 316L

10 PCS filling nozzles,made by SUS 316L

Caps vibrator: feeding caps automatically

2 PCS capping heads with high accuracy

Finished products

This liquid filling line is optional,more details contact us now

NO.1: CX-GP bottle feeding turntable ,feeding round bottles automatically

NO.2: CX-QXJ air jet bottle washing machine

Fit for both glass botthe and pet bottle,round/square/flat/oval...different shape bottle

NO.3: CX-GFT Filling and capping machine

NO.4: CX-SP bottle collecting turntable ,collecting bottles automatically

Application:

Product Characteristics:

1.The parts which contact liquid are SUS316L stainless steel and others are SUS304 stainless steel

2.Including feeder turntable,effective cost/space saving

3.It has intuitive and convenient operation, measuring accurate, positioning precision

4.Fully in accordance with the GMP standard production and passed CE certification

5. Optional Siemens Touch screen/PLC

6.No bottle no filling/plugging/capping

7.HS Code:8422303090

Main technical Parameters:

|

Applied Bottle |

50-500 ml |

|

Productive Capacity |

10-30pcs/min 2 filling nozzles 10-50pcs/min 4filling nozzles 50-60pcs/min 6 filling nozzles 60-80pcs/min 8 filling nozzles 80-100pcs/min 10 fillling nozzles 100-120pcs/min 12 filling nozzles |

|

Filling Tolerance |

0-2% |

|

Qualified Stoppering |

≥99% |

|

Qualified cap putting |

≥99% |

|

Qualified capping |

≥99% |

|

Power Supply |

380V ,50HZ |

|

Power |

1.5KW |

|

Net Weight |

600KG |

|

Dimension |

2500(L)×1000(W)×1700(H)mm |

Famous brand electrical parts:

|

Machine frame |

SUS304 Stainless steel |

|

|

The parts which contact liquid |

SUS316L Stainless steel |

|

|

Peristaltic pump |

piston pump |

|

|

Main Motor |

ABB |

Switzerland |

|

Inverter |

Japan |

|

|

Air Switch |

Schneider |

France |

|

Contactor |

Schneider |

France |

|

Relay |

Omron |

Japan |

|

OFA |

Autonics |

Korea |

|

Bearing |

IGUS |

Germany |

|

CAM indexer |

Shangdong |

China |

|

Turntable |

Plastic POM |

Japan |

|

Cylinder |

AIRTAC |

Taiwan |

|

Touch screen |

Siemens (optional) |

Germany |

|

PLC |

Siemens |

Germany |

|

Servo motor |

Delta |

Taiwan |

The machine adopt famous brand component parts to keep machine with high quality. but we are factory,so our price is competive.we hope you will be our customer,and you will be satisfacted with our product and service

Customers feedback:

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you need to change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.

Guarantee of quality :

The Manufacturer shall guarantee the goods are made of Manufacturer’s best materials, with first class workmanship, brand new, unused and correspond in all respects with the quality, specification and performance as stipulated in this Contract. Quality guarantee period is within 12 months from B/L date. The Manufacturer would repair the contracted machines free of charge during the quality guarantee period. If the break-down can be due to the improper use or other reasons by the Buyer, the Manufacturer will collect repair parts cost.

Installation and Debugging:

The seller would dispatch his engineers to instruct the installation and debugging. Cost would be bear on buyer’s side

(round way flight tickets, accommodation fees in buyer country). The buyer should provide his site assistance for the installation and debugging.

Q1.Are you the factory?

A1:Yes,we are 18 YEARS manufacturer of filling-capping-labeling-bottle washing machine, our factory is in Shanghai.

Q2.What's the payment terms and trade terms for new customers?

A2: Payment terms:T/T,L/C,D/P,O/A, Western Union etc.

Trade terms:EXW,FOB,CIF,C&F...

Q3:What's the Minimum Order Quantity and warranty?

A3:MOQ:1 set

Warranty:12 months,some customized products will be 24 months.

Q4:Your certification please?

A4:CE/ISO/TUV/GMP