- Product Details

- {{item.text}}

Quick Details

-

Raw materal:

-

corn meal and the other grains powder

-

Applications:

-

corn flakes

-

Screw diameter:

-

65mm;70mm;85mm;95mm

-

Energy source:

-

Electricity/Gas/Diesel/LPG/Steam

-

Motor brand:

-

Siemens, ABB or customized

-

Inverter brand:

-

Delta, Siemens, ABB or customized

-

Bearing brand:

-

SKF.NSK,etc

-

extruder:

-

Twin-screw extruder

Quick Details

-

Place of Origin:

-

Shandong, China

-

Name:

-

corn flakes making machine

-

Production Capacity:

-

150kg-350kg/h

-

Raw materal:

-

corn meal and the other grains powder

-

Applications:

-

corn flakes

-

Screw diameter:

-

65mm;70mm;85mm;95mm

-

Energy source:

-

Electricity/Gas/Diesel/LPG/Steam

-

Motor brand:

-

Siemens, ABB or customized

-

Inverter brand:

-

Delta, Siemens, ABB or customized

-

Bearing brand:

-

SKF.NSK,etc

-

extruder:

-

Twin-screw extruder

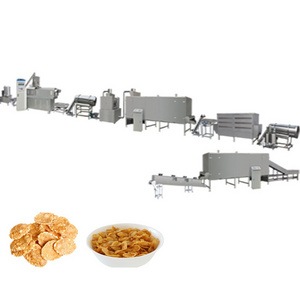

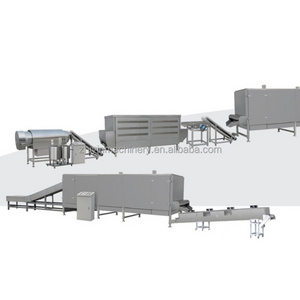

Automatic Corn Flake Maize Flakes Breakfast Cereal Making Machine Food Processing Line from Phenix Machinery

1. Description

Corn flakes making machine is a very popular equipment line. It takes corn flour as main raw material, it is very crispy after extruding, granulating,flaking,frying, seasoning. The outstanding characteristic of flakes is containing abundant compound carbohydrate and dietary fiber. We can also add some trace elements and minerals.

2.Flow chart:Mixing system---Extrusion system---Flaking system---Drying system---Sugar Spraying system ---Drying system---- Packing system

3.Technical Parameters

| Model | Power(kw) | Capacity(kg/h) | Dimension(m) |

| PX65-111 | 130 | 100-150 | 39x1.3x2.5 |

| PX70 | 160 | 200-260 | 41x1.5x2.5 |

| PX85 | 190 | 300-500 | 43x3.5x4.3 |

Outside package: Standard export wooden case. Inner package: stretch film.

a. We can keep product design in the same level with internationally advanced technology consistently.

b. We have high diathesis staff and excellent processing equipment, and quality control runs through the whole production process from parts stock to the beginning of production.

c. We can guarantee customers superior quality machines up to design requirements and perfect working state.

d. Our technicians can also provide all kinds of relevant technology to make the food production clean, healthy and safe.

e. We will dispatch our technicians to your factory to guide you installation and commissioning work and training your operator.

f. We provide 1 year complete Guarantee and life-time maintenance service.