- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4700*1100*1600

-

Power (kW):

-

16.5

-

Weight (KG):

-

1500 kg

-

Applicable Industries:

-

Furniture Factory, woodworking factory

-

Panel Feed Speed(m/min):

-

26m/min

-

Band Thickness:

-

0.4-3mm

-

Edge Band Width:

-

12-60mm

-

Panel Thickness:

-

10-55mm

-

Min. length of workpiece:

-

80mm

-

Feeding speed:

-

18m~22m/min

-

Air Pressure:

-

0.6MPa-0.8Mpa

-

Control type:

-

PLC

-

Min. width of workpiece:

-

80mm

-

Weight:

-

1500kg

-

Power:

-

16.5kw

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Marketing Type:

-

New Product 2020

-

Machinery Test Report:

-

Provided

-

Certification:

-

ISO

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Lian Wang

-

Voltage:

-

380V,can customize 220V

-

Dimension(L*W*H):

-

4700*1100*1600

-

Power (kW):

-

16.5

-

Weight (KG):

-

1500 kg

-

Applicable Industries:

-

Furniture Factory, woodworking factory

-

Panel Feed Speed(m/min):

-

26m/min

-

Band Thickness:

-

0.4-3mm

-

Edge Band Width:

-

12-60mm

-

Panel Thickness:

-

10-55mm

-

Min. length of workpiece:

-

80mm

-

Feeding speed:

-

18m~22m/min

-

Air Pressure:

-

0.6MPa-0.8Mpa

-

Control type:

-

PLC

-

Min. width of workpiece:

-

80mm

-

Weight:

-

1500kg

-

Power:

-

16.5kw

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

Showroom Location:

-

None

-

Marketing Type:

-

New Product 2020

-

Machinery Test Report:

-

Provided

-

Certification:

-

ISO

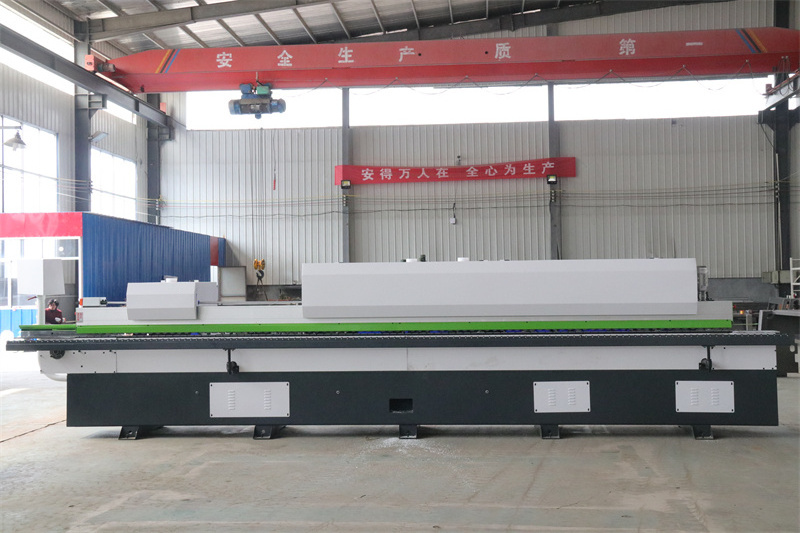

Rough and fine trimming with corner cabinet panel board automatic edge banding machine f200a

Technical Parameter

| Model name | LW 468 |

| Dimension | 4700*1100*1600mm |

| Weight | 1500kg |

| working pressure | 0.6mpa |

| feeding speed | 12-24m/min |

| Sheet thickness | 10-60mm |

| Sheet length | ≥150mm |

| Sheet width | ≥ 80mm |

| edge band thickness | 0.4-3mm |

| edge band width | 12-60mm |

| Total power | 16.5kw |

Configuration

| Conveying motor | Taiwan Wanxin | Cylinder | Airtac |

| High-speed motor | Tianjin Anquan | Solenoid valve | Yiri |

| Touch screen | Taiwan Taida | Inverter | Siemens |

| Travel switch | Omron | Pressure regulating | Yiri |

| Flush rail | Taiwan Shangyin | Other configuration | Electric lift |

Detail Description

1 100% Copper motor ,Long service life, one year quality assurance, strong power

2 Gluing device,The glue pot is heated to melt the glue, and the glue is evenly spread on the board and the edge band through a special conveying structure. Press the edge band and the board tightly by the pressing wheel

3 Front and back flush device .Through the structure of automatic profiling and high-frequency high-speed motor, the cut surface is smooth

4 Roughly repair device .The rough trimming knife is a flat knife, which is used to repair and process the excess edge banding material on the upper and lower parts of the sheet edge band. The high-frequency and high-speed motor is used to realize fast cutting. If the thickness of the edge band exceeds 1.2mm, it is recommended to choose a rough repair.

5 Finishing device ,The finishing is an R-shaped knife, which is used to repair the excess edge banding material after rough trimming of the upper and lower edge bands of the processed plate, and at the same time make the arc transition between the plate and the edge band naturally

6 Scraping edge device .It is used to eliminate the ripple marks caused by the cutting process of the non-linear motion of the trimming (trimming knife and the knife marks left by the r-shaped fillet), so that the upper and lower parts of the plate are smoother and tidy

7 Polishing device .The cotton polishing wheel polishes and cleans the processed plates, removes the excess amount of glue between the edge banding tape and the plate, and makes the edge banding end surface more natural and smooth

The effect

FAQ

1,Can you offer good price with fine quality also?

Surely,if without quality,we cannot win long market.we will loose long-terms customers.Quality is our responsibility.we must produce and test machine well.Becasue we are always expecing long term business.Regarding the price.

we are not sure if it is lowest or highest,But we will be offering reasonble.We don’t want heavy profits,we want a acceptable price to you,and we are expecting a bigger quantities of sales for different wood machines

2,We will be protetcted if we are paying for orders?

Surely yes,we have been exported 1000000$ different wood machine every year,We received the payment,we should produce for you and ship to you without delay. It is honesty and reputy.We could understand that you paid,you want to see machines soon and use soon. and these years alibaba trade assurance you could rely on,you will be protected very well.

3,What's your warranty? can you do more service for us? we wish woud be protected after purchasing machine.

We are pleased to give life continious aftersales service. within 12 months, if spareparts broken,we will send you new for change. we would like to help to solve any troubles when you use machine at any time.and don’t be worried,we will keep opening 24 hours for all customers problem or difficilaty. we must help to make solutions within 48 hours .

4,What's your production time? we want faster shipping time also.

mostly machine we have in stock, some machine we produce need about 7-10days. make fast shipment always. shipping time depends on shipping company.