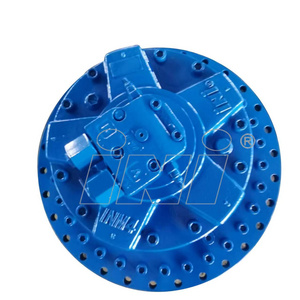

20+

Years CNC Machining

Supply Ability:

300000

Product per month

Machinery Axis:

3,4,5,6

Tolerance:

0.01~0.005

mm

Certification:

ISO9001,

ISO13485,

SGS2,

IATF16949,

As9100

,CE,CQC,ROHS.