- Product Details

- {{item.text}}

Quick Details

-

Marketing Type:

-

New Product 2021

-

Brand name:

-

BIDRAGON

-

nail making speed:

-

150Pcs/min

-

Max.Length of Nail:

-

100mm

-

Min.Length of Nail:

-

35mm

-

Max.Diameter of Nail:

-

4.5mm

-

Min.Diameter of Nail:

-

2.38mm

-

Name:

-

Screw Making Machine

-

Related machine:

-

Nial Making Machine

-

WhatsApp/ Wechat:

-

+86 13213263312

-

Voltage:

-

380V or customized

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

BIDRAGON

-

Weight (KG):

-

250

-

Marketing Type:

-

New Product 2021

-

Brand name:

-

BIDRAGON

-

nail making speed:

-

150Pcs/min

-

Max.Length of Nail:

-

100mm

-

Min.Length of Nail:

-

35mm

-

Max.Diameter of Nail:

-

4.5mm

-

Min.Diameter of Nail:

-

2.38mm

-

Name:

-

Screw Making Machine

-

Related machine:

-

Nial Making Machine

-

WhatsApp/ Wechat:

-

+86 13213263312

-

Voltage:

-

380V or customized

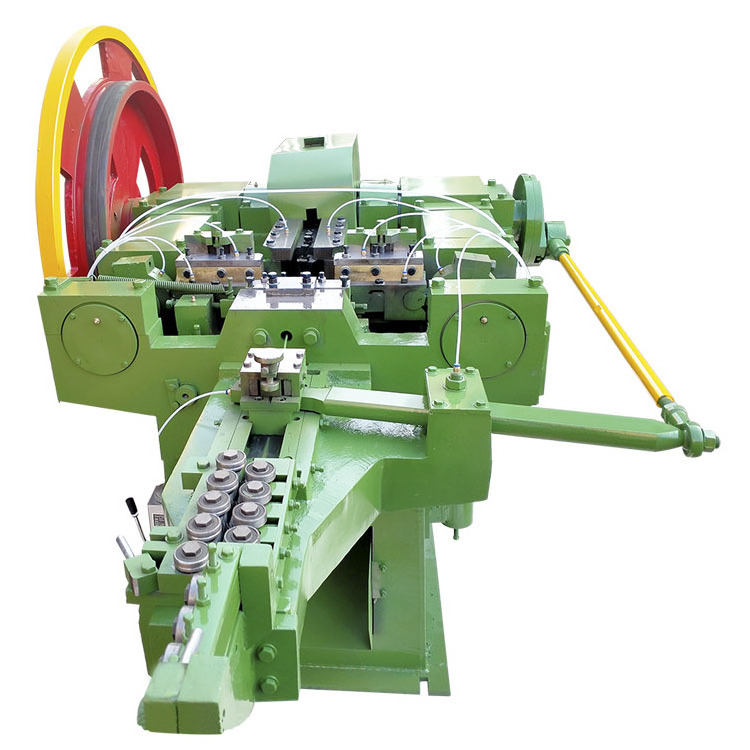

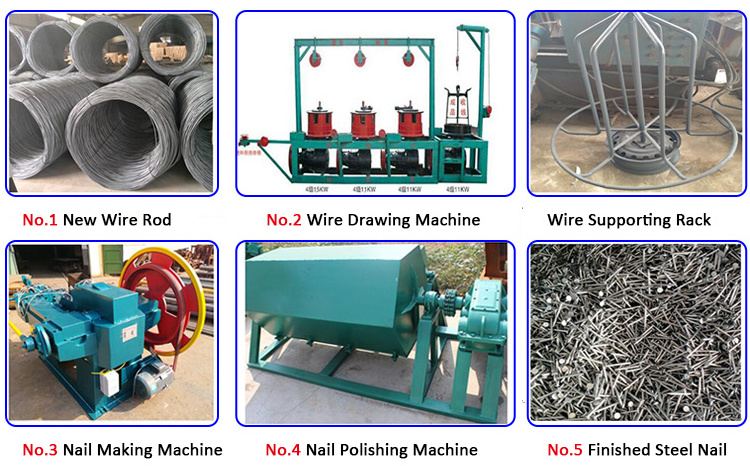

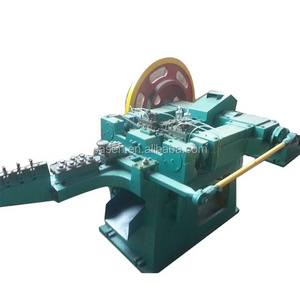

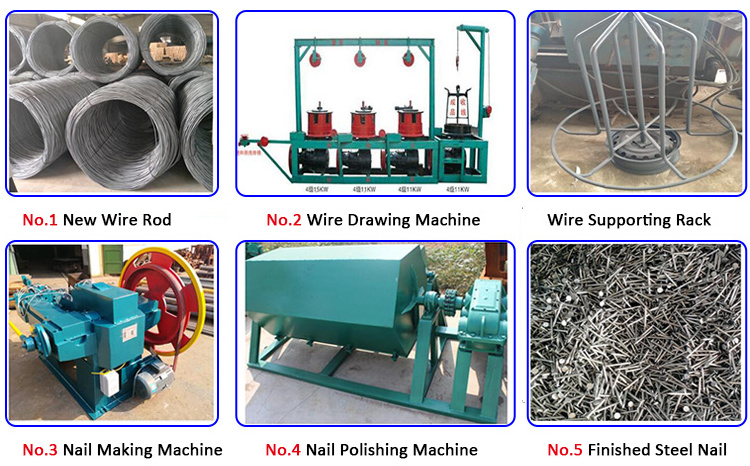

Screw nail making line is consist of t he cold heading machine and thread rolling machine. C old heading machine cuts a length of wire and makes two blows on the end, forming a head. In the head slotting machine, the screw blanks are clamped in the grooves around the perimeter of the wheel. A circular cutter slots the screws as the wheel revolves.

Cold heading

procedure:

Cold heading

procedure:

Wire is fed from a mechanical coil through a prestraightening machine. The straightened wire flows directly into a machine that automatically cuts the wire at a designated length and die cuts the head of the screw blank into a preprogrammed shape. The heading machine utilizes either an open or closed die that either requires one punch or two punches to create the screw head. The closed (or solid) die creates a more accurate screw blank. On average, the cold heading machine produces 100 to 550 screw blanks per minute.

Thread rolling procedure:

Once cold headed, the screw blanks are automatically fed to the thread-cutting dies from a vibrating hopper. The hopper guides the screw blanks down a chute to the dies, while making sure they are in the correct feed position.

The blank is then cut using one of three techniques. In the reciprocating die, two flat dies are used to cut the screw thread. One die is stationary, while the other moves in a reciprocating manner, and the screw blank is rolled between the two. When a centerless cylindrical die is used, the screw blank is rolled between two to three round dies in order to create the finished thread. The final method of thread rolling is the planetary rotary die process. It holds the screw blank stationary, while several die-cutting machines roll around the blank.

Our product pictures:

|

|