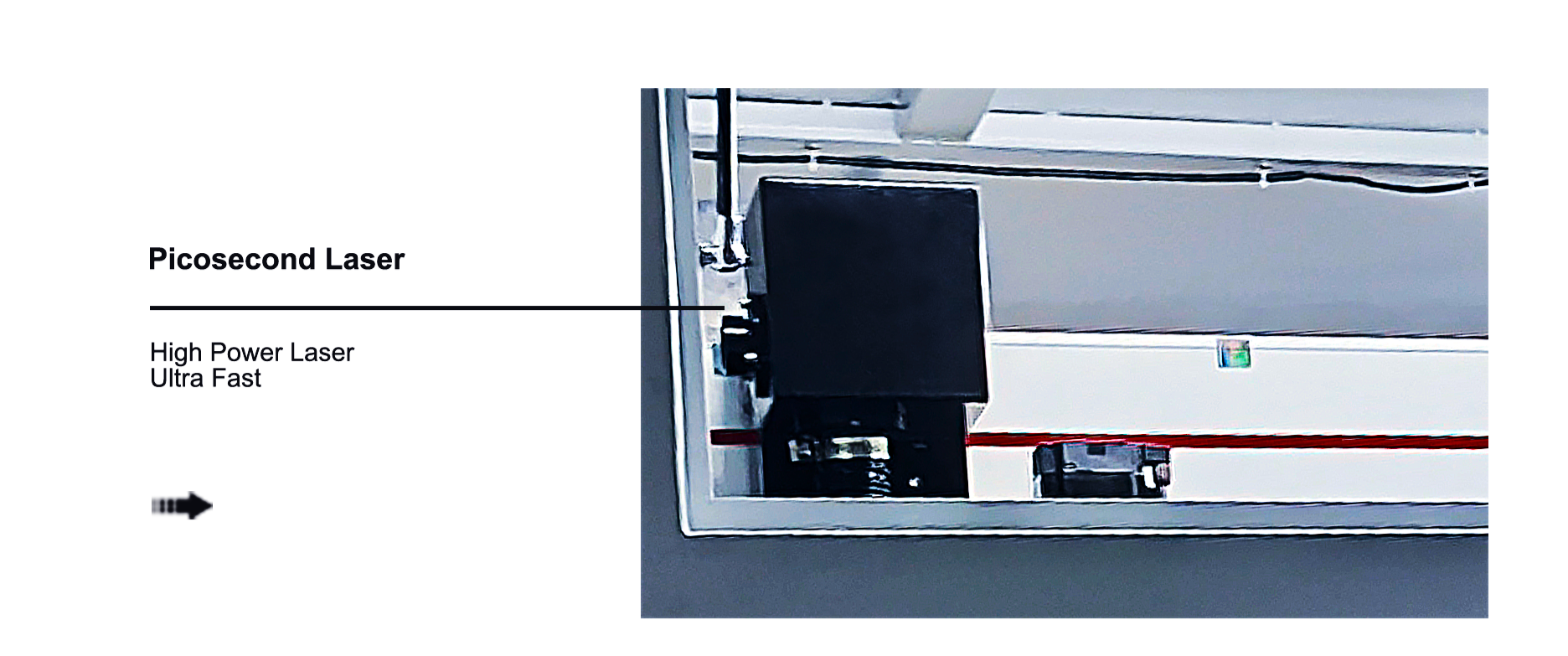

The light source utilizes a high-power picosecond laser with a high peak power and narrow pulse width.

- Product Details

- {{item.text}}

Quick Details

-

Cutting Area:

-

600mm*700mm

-

Cutting Thickness:

-

0.03~25mm

-

Control Software:

-

self-develop HTI

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CKD

-

Weight (KG):

-

2000 KG

-

Core Components:

-

laser, axis

-

Products handled:

-

galss

-

Work Size:

-

600*700mm

-

Accuracy:

-

±0.01mm

-

Thickness:

-

0.03-25mm

-

Speed:

-

0-500mm/s

-

Chipping:

-

≤5μm

-

wavelength coverage:

-

1064nm

-

cutting speed:

-

0-500mm/s

-

impulse frequency:

-

1-100khz

-

cutting thickness:

-

0.03-25mm

-

Power:

-

10/20/30/50/60/80w

Quick Details

-

Laser Type:

-

Infrared Picosecond

-

Cutting Speed:

-

0-500mm/s

-

Cooling Mode:

-

WATER COOLING

-

Cutting Area:

-

600mm*700mm

-

Cutting Thickness:

-

0.03~25mm

-

Control Software:

-

self-develop HTI

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

CKD

-

Weight (KG):

-

2000 KG

-

Core Components:

-

laser, axis

-

Products handled:

-

galss

-

Work Size:

-

600*700mm

-

Accuracy:

-

±0.01mm

-

Thickness:

-

0.03-25mm

-

Speed:

-

0-500mm/s

-

Chipping:

-

≤5μm

-

wavelength coverage:

-

1064nm

-

cutting speed:

-

0-500mm/s

-

impulse frequency:

-

1-100khz

-

cutting thickness:

-

0.03-25mm

-

Power:

-

10/20/30/50/60/80w

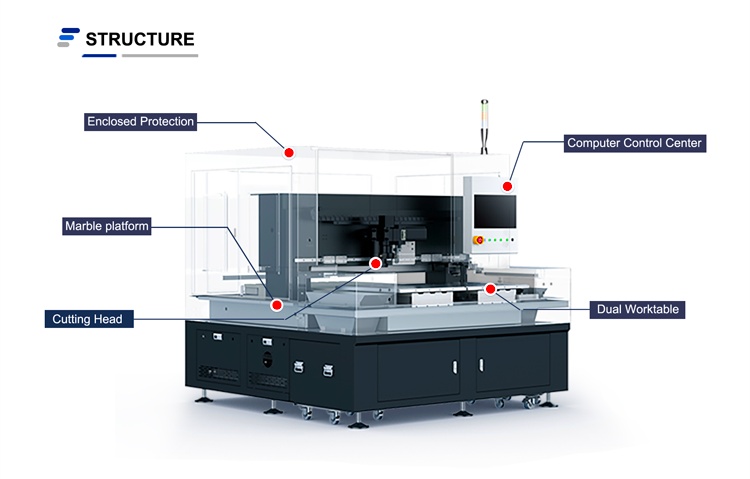

Portable Glass Laser Cutting Machine

Product Description

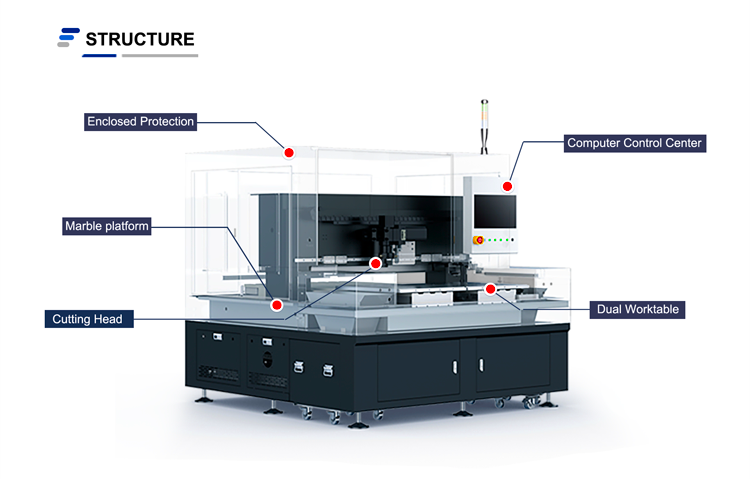

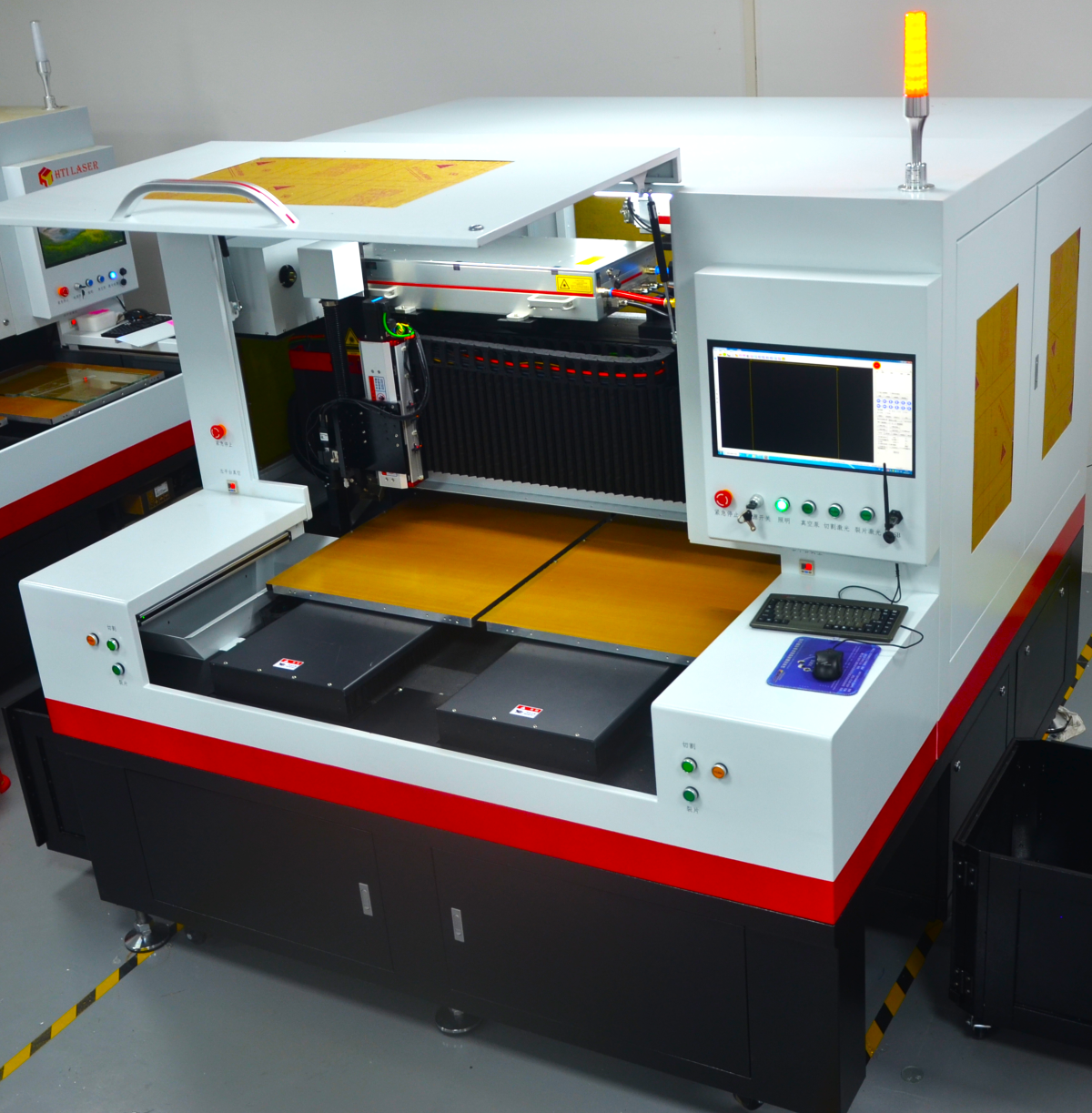

Picosecond Laser

Self-Develop Cotrol System

Help users quickly understand,interact, and interact withcomputer machines

Self Develop Cutting Head

The self-developed glass cutting head features imported lenses with fine beam spots and long focal depth.

The advanced laser cutting system, featuring a high-power picosecond laser, a self-developed cutting head with premium optics, and a robust motion control with PSO, is capable of versatile cutting and breaking operations up to 19mm thickness, with precision alignment and high-quality electrical components for reliable and efficient industrial glass processing.

|

Application Industry

|

Types of Glass Used

|

|

Glass Processing Industry

|

Optic/UTG/Willow/Brittle Biomedical glass

|

|

Real Estate Industry

|

Architectural decoration, Bathroom glass

|

|

Automobile Industry

|

Car glass/Instrumentation panel glass

|

|

Communication Media Industry

|

Mobile/Watch sapphire cover, Camera/CCTV Lens glass

|

|

Home Appliance Industry

|

Home appliance glass panel, Lighting glass

|

|

New Energy Industry

|

Photovoltaic glass

|

|

Glass type

|

|

|

Ultra Clear Glass

|

Refers to a category of glass with exceptional clarity.

|

|

Plain White Glass

|

A type of glass that is uniformly white and used for various applications.

|

|

High Borosilicate Glass

|

Known for its high boron content, providing greater resistance to thermal stress.

|

|

Quartz Glass

|

A high purity glass with unique properties such as a high melting point and resistance to chemicals.

|

|

Phone Glass Cover

|

Protective glass used as a cover for smartphone screens.

|

|

Car Glass

|

Glass used in automotive applications, such as windshields or windows.

|

|

Camera Glass Cover

|

Protective glass cover for camera lenses or display screens.

|

|

LCD Screen

|

Liquid crystal display screen used in various electronic devices.

|

|

K9 Glass

|

A type of optical glass often used in manufacturing optical instruments.

|

|

Filter Cutting

|

The process of cutting glass or other materials to create filters for various applications.

|

|

Mirror Cutting

|

The process of cutting glass to produce mirror surfaces for decorative or functional use.

|

1. High Cutting Quality: The cutting process is capable of producing a high-quality surface finish.

2. No Taper: The edges of the cut do not gradually narrow, maintaining parallelism of the cut surface.

3. No Burrs: The cutting process leaves no sharp edges or burrs, eliminating the need for additional deburring operations.

4. Small Chipping: Minimal chipping occurs at the material edges during the cutting process.

5. Low-Cost: The operational costs of the equipment or technology are low.

6. High-Yield Rate: The process allows for more material to be processed within a given time frame, increasing production efficiency.

7. Low Consumables and Energy-Saving: The production process uses fewer auxiliary materials and consumes less energy.

8. Irregular-Shape High-Speed Cutting: The technology enables high-speed cutting of materials with irregular shapes.

9. No Pollution: The cutting process does not produce environmental pollutants.

10. No Powder and No Wastewater: The cutting process is environmentally friendly, as it does not generate dust or wastewater.

2. No Taper: The edges of the cut do not gradually narrow, maintaining parallelism of the cut surface.

3. No Burrs: The cutting process leaves no sharp edges or burrs, eliminating the need for additional deburring operations.

4. Small Chipping: Minimal chipping occurs at the material edges during the cutting process.

5. Low-Cost: The operational costs of the equipment or technology are low.

6. High-Yield Rate: The process allows for more material to be processed within a given time frame, increasing production efficiency.

7. Low Consumables and Energy-Saving: The production process uses fewer auxiliary materials and consumes less energy.

8. Irregular-Shape High-Speed Cutting: The technology enables high-speed cutting of materials with irregular shapes.

9. No Pollution: The cutting process does not produce environmental pollutants.

10. No Powder and No Wastewater: The cutting process is environmentally friendly, as it does not generate dust or wastewater.

customization

Our laser glass cutting machine is designed with customization at its core. We understand that every client has unique requirements and expectations when it comes to precision cutting technology. That's why we offer a comprehensive customization service that allows you to tailor the machine's appearance and functionality to your specific needs. Whether you're looking for a bespoke design to match your brand aesthetic or you require specialized features to enhance productivity and efficiency, our team of experts is here to work with you. We can modify the machine's specifications, integrate advanced technological capabilities, and ensure that the final product is a perfect fit for your business operations. Our commitment to customization doesn't end with he initial design phase. We also provide ongoing support and software updates to ensure that your laser glass cutting machine

remains at the forefront of innovation and continues to meet your evolving needs over time. Partner with us to bring your vision to life and experience the difference that a truly bespoke laser glass cutting solution can make.

specifications

|

Specification

|

Description

|

|

The parameters of the cutting laser source

|

|

|

Cooling Method

|

Water cooling

|

|

Pulse Width

|

<10ps

|

|

Pulse Frequency

|

1Hz - 1000kHz

|

|

Wavelength

|

1064nm

|

|

Beam Quality

|

M^2 < 1.2

|

|

Power

|

50W (options: 10W, 20W, 30W, 60W, 80W, etc.)

|

|

Laser Type

|

Infrared picosecond pulse laser

|

|

Cutting Performance

|

|

|

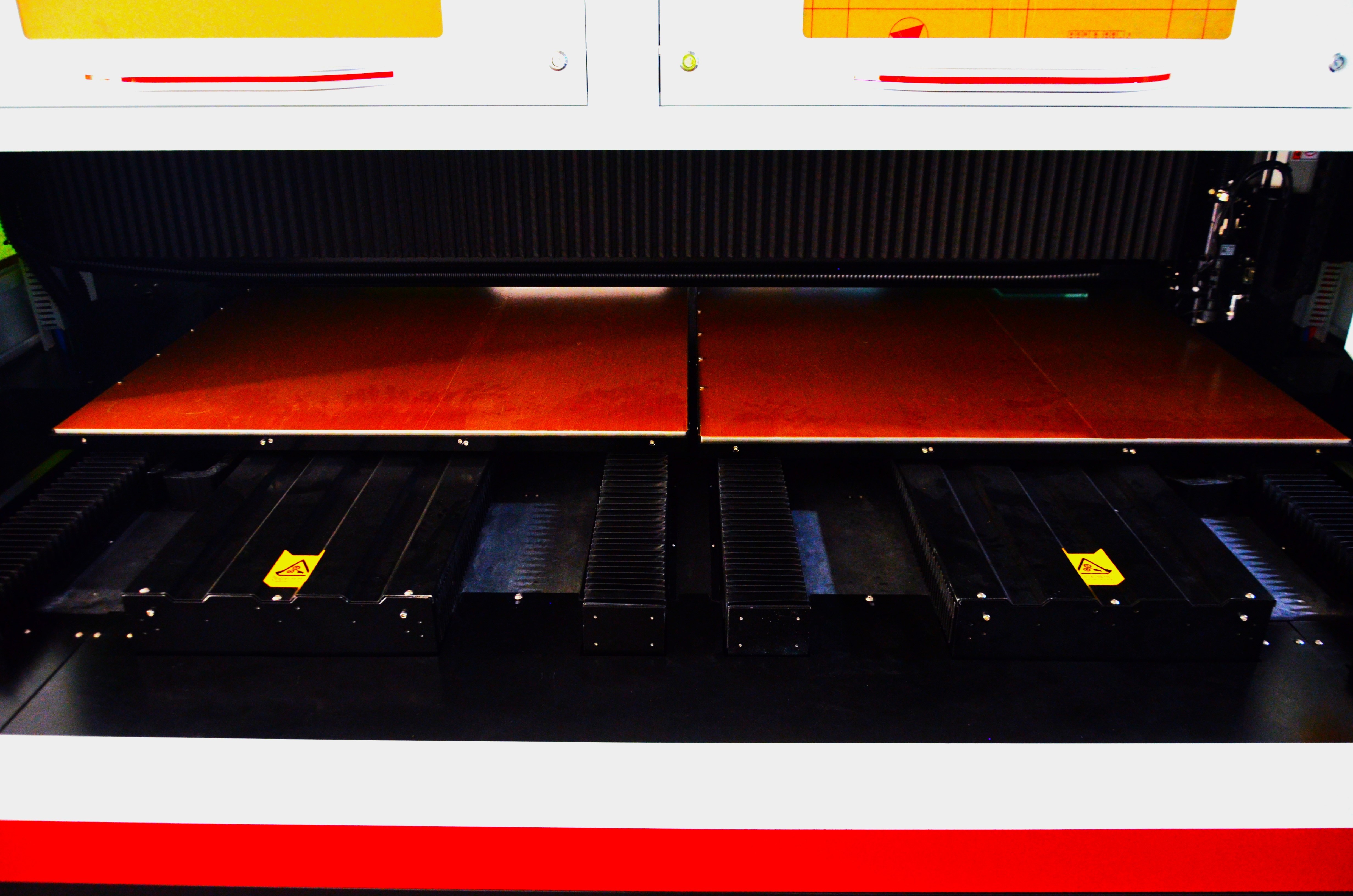

Drive Motor

|

XY Linear Motor + Optical Grating Scale

|

|

Positioning Accuracy

|

±2um

|

|

Repeatability

|

±1.5um

|

|

Acceleration

|

1G

|

|

Linear Speed

|

Up to 1000mm/s

|

|

Cutting Speed

|

Adjustable from 0-500mm/s

|

|

Cutting Thickness

|

Ultra-clear glass single cut ≤19mm, Blue glass double cut ≤19mm (laser power and cutting head focus depth may need to be selected based on product material, thickness, and cutting speed requirements)

|

|

Minimum Cutting Burr

|

≤5um

|

|

Cutting Precision

|

±0.01mm

|

|

X/Y Cutting Range

|

610×700mm

|

|

Parameters of power, size, and weight

|

|

|

Weight

|

Approximately 2000KG /2500KG/3000KG

|

|

Machine Dimensions (Option 1)

|

Length 1700mm x Width 1700mm x Height 1960mm

|

|

Machine Dimensions (Option 2)

|

Length 2150mm x Width 2080mm x Height 1960mm

|

|

Machine Dimensions (Option 3)

|

Length 2550mm x Width 2080mm x Height 1960mm

|

|

Voltage, Power

|

<5KW, AC220V

|

Sample

Exhibition

Customer visits and services

Product packaging

FAQ

Q1: Could I visit your factory?

A1: Yes, We will warmly welcome you anytime. It's tooks about 1 hours from

bao'an International airport to our factory.

Q2: How many years do you do this business?

A2: From 2008.

Q3: Does your factory have the design & development capacities, we need customized products?

A3: yes. The staffs in our design department are well experienced in laser machine, with more than 5 to 10 years experience.

We can make customized products especially for you; Please kindly contact us for more details.

Q4: What is payment terms?

A4: 100% T/T advanced.

Q5: About shiping?

A5: 3-10 days after payment for standard products, please consult our sales for customized products.

Q6: How about your after service?

A6: Our engineers who has long time professional experience and sales will help you within 24h.

Q7: Do you have patents or core technology?

A7: Yes, for details, please contact our sales.

Q8: Where have you sold your products?

A8: Europe, Americas, Africa, and Asia.

A1: Yes, We will warmly welcome you anytime. It's tooks about 1 hours from

bao'an International airport to our factory.

Q2: How many years do you do this business?

A2: From 2008.

Q3: Does your factory have the design & development capacities, we need customized products?

A3: yes. The staffs in our design department are well experienced in laser machine, with more than 5 to 10 years experience.

We can make customized products especially for you; Please kindly contact us for more details.

Q4: What is payment terms?

A4: 100% T/T advanced.

Q5: About shiping?

A5: 3-10 days after payment for standard products, please consult our sales for customized products.

Q6: How about your after service?

A6: Our engineers who has long time professional experience and sales will help you within 24h.

Q7: Do you have patents or core technology?

A7: Yes, for details, please contact our sales.

Q8: Where have you sold your products?

A8: Europe, Americas, Africa, and Asia.

Hot Searches