- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

6000*4000*1700mm

-

Weight:

-

1000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

Customized

-

Power:

-

20kw

-

Key Machines:

-

Chili Dryer, Chili color sorter, Chili tail remover, Chili powder making machine, Chili powder packaging machine

-

Name:

-

Paprika Making Machines

-

Material:

-

Stainless steel or customized

-

Applicable Industries:

-

Commercial, agricultural or plant

-

Application:

-

Chili, onion, ginger, turmeric

-

Function:

-

Making chili powder

-

Certification:

-

CE ISO

-

Color:

-

Customer Demand

-

Advantage:

-

Easy to operate

-

MOQ:

-

1 Set

-

Key words:

-

chili machines

Quick Details

-

Machinery Capacity:

-

100-200kg/h

-

Brand Name:

-

BAIXIN

-

Year:

-

2022

-

Dimension(L*W*H):

-

6000*4000*1700mm

-

Weight:

-

1000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

Customized

-

Power:

-

20kw

-

Key Machines:

-

Chili Dryer, Chili color sorter, Chili tail remover, Chili powder making machine, Chili powder packaging machine

-

Name:

-

Paprika Making Machines

-

Material:

-

Stainless steel or customized

-

Applicable Industries:

-

Commercial, agricultural or plant

-

Application:

-

Chili, onion, ginger, turmeric

-

Function:

-

Making chili powder

-

Certification:

-

CE ISO

-

Color:

-

Customer Demand

-

Advantage:

-

Easy to operate

-

MOQ:

-

1 Set

-

Key words:

-

chili machines

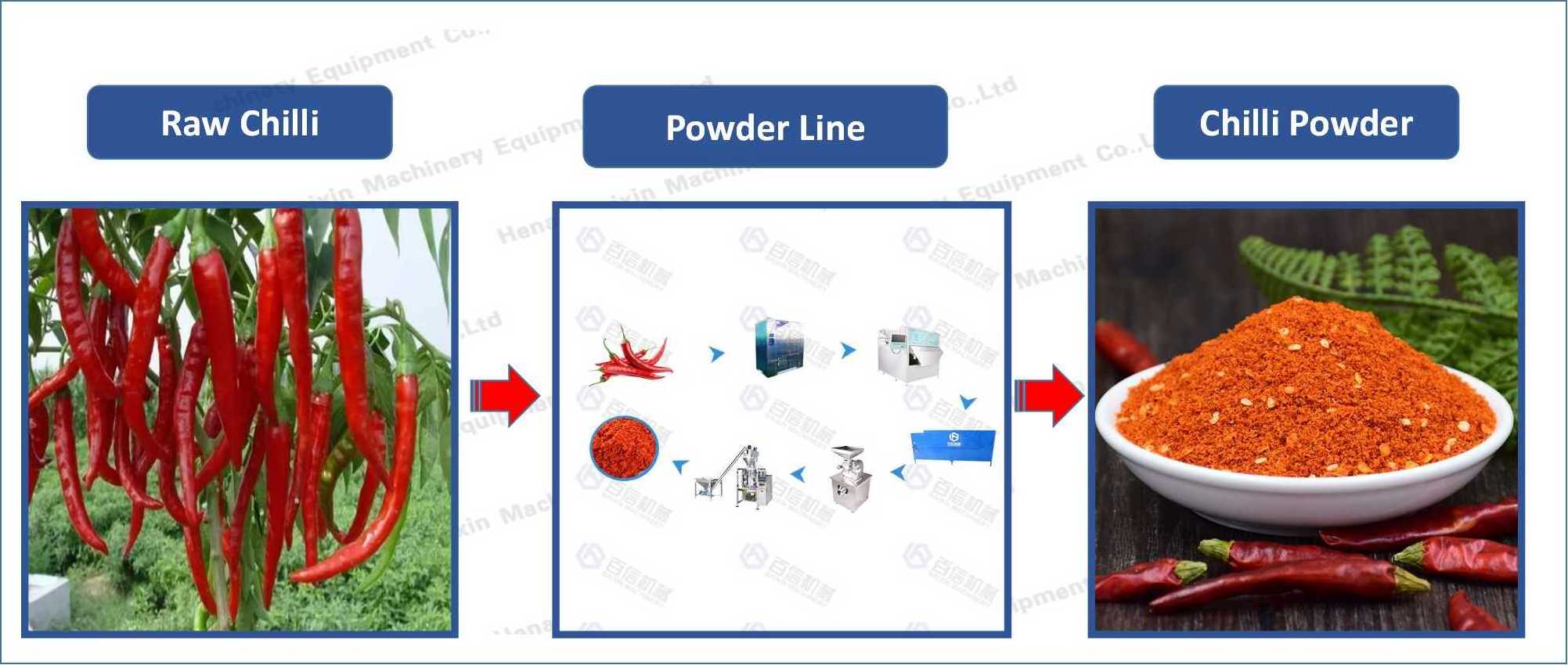

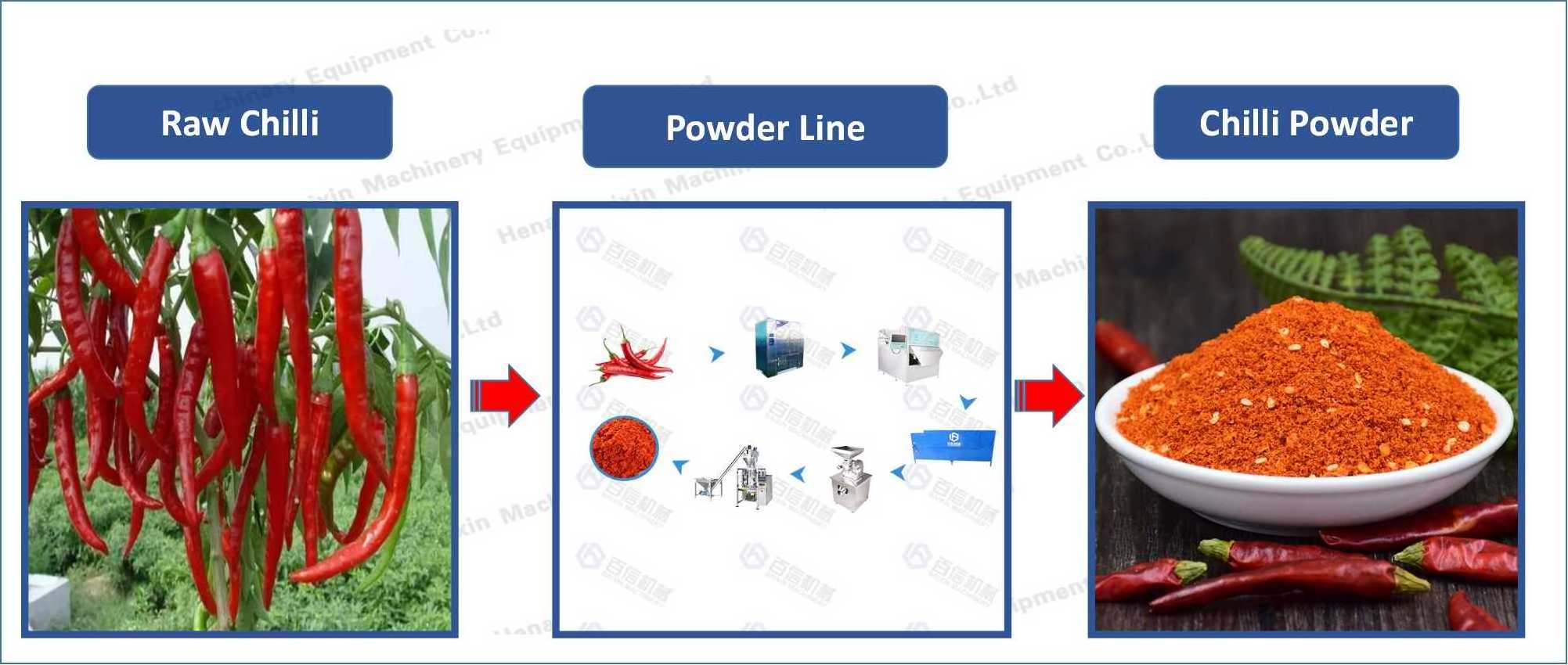

The chili processing line has continuous automatic production, fast processing speed, high capacity, good quality and a low-temperature drying method maintains the original flavor of chili.

It includes chili dryer,chili color sorter,chili tail remover,chili grinder,chili powder packaging machine. The chili processing line can also be used for other spices such as garlic, ginger, onion, etc.

In addition, dry ground chili are easier to store and more versatile, avoiding economic losses caused by seasonal storage and mildew deterioration.The chili processing line adopts advanced technology, high chill capacity and direct sales at factory prices. This is the best choice for chili business and the most ideal equipment for chili processing at present.

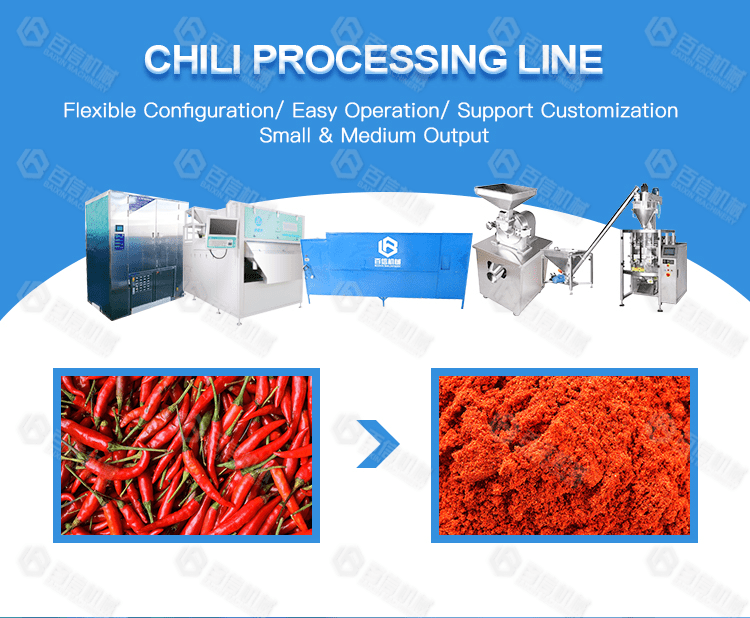

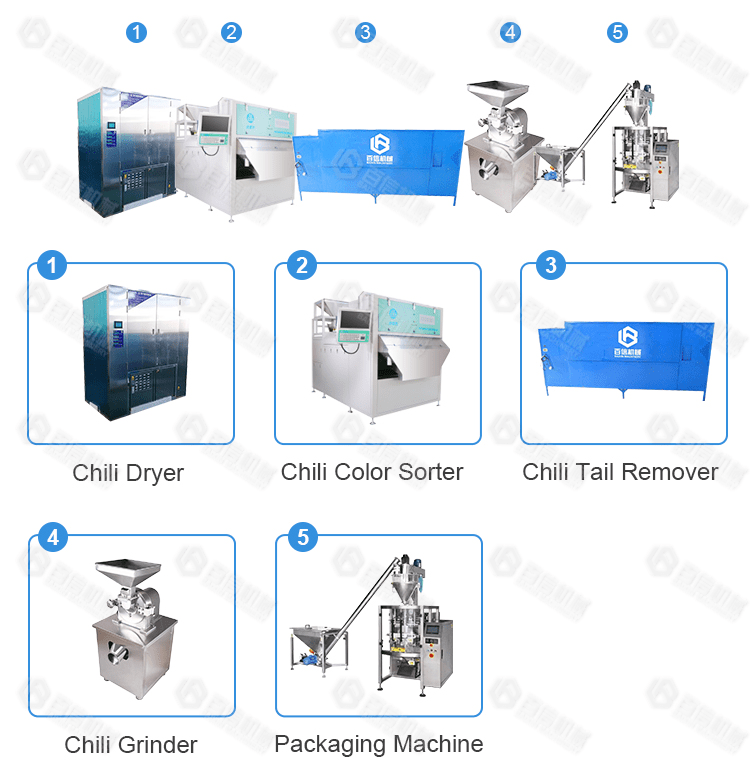

1. Chilli Dryer: Used to remove moisture from chill, turning wet chill into dry chill in preparation for the next step of grinding. This dryer can well retain the nutritional value and taste of chill, and only plays a role in drying.

2. Chilli Color Sorter: Sort the dried peppers, remove damaged, shriveled, mildewed peppers, or remove stalks, leaves, stones and other sundries in the peppers. The machine can accurately sort out high-quality peppers according to the color difference of peppers, with fast sorting speed and high efficiency. The selected peppers are of high quality, and the net selection rate can reach more than 99%.

3. Chili Tail Remover: The main function of the chili tail removal machine is to remove the tail of the chili, and the value of the processed chili is doubled. The equipment has fast processing speed, low chili loss, and is suitable for different varieties of chili.

4. Chili powder making machine: Grind dried chili to a fineness of 10-120 mesh. The chili grinder is air-cooled or water-cooled and can work continuously for a long time .

5. Chili Powder Packing Machine: Generally speaking, chili powder business requires automatic chili powder packaging equipment. The chili powder packaging machine has a PLC control system, which is intelligent and controllable, and can be quickly adjusted according to customer packaging requirements. Packaging weight and quantity are automatically adjusted.

| 100-200kg/h small capacity chilli powder processing line | ||||

| No. | Machine name | Power | Size | Capacity |

| 1. | Chili Dryer | 3KW | 2100*930*2100mm | 200-300kg/h |

| 2. | Chili Color Sorter | 7.2KW | 4464*1820*2577mm | 500kg/h |

| 3. | Chili Tail Remover | 3kw | 4200*800*1200mm | 200-300kg/h |

| 4. | Chilli Grinder | 5.5KW | 750*600*1260mm | 30-150kg/h |

| 5. | Packing Machine | 1.6KW | 700*750*1650mm | 30-60 packs/min |

| The Chili powder processing line can be equipped with the user's requirement and the production demands. | ||||

The machines will be shock-proof and pressure-proof packaging before wooden packing, and then will be packed in wooden boxes, finally put into the container. It can also be packed according to the customer's request.