- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 440V, 230V, 203V

-

Dimension(L*W*H):

-

depends

-

Weight:

-

6200 KG

-

Application:

-

Diamond Washing Equipment

-

Feeding size:

-

230mm

-

Power:

-

3-66Kw

-

Capacity:

-

5-300tons per hour

-

Screen size:

-

5-50mm

-

Hot selling Model:

-

JXSC-600,JXSC-900,JXSC-1500,JXSC-1800,JXSC-2100

-

Installation:

-

Field installation,General Arrangement,technical support,Online guide

-

Keywords:

-

Scrubber Trommel Wash Plant

-

Driving system:

-

advanced rubber tires driving

Quick Details

-

Production Capacity:

-

100%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

Eastman/JXSC

-

Voltage:

-

380V, 440V, 230V, 203V

-

Dimension(L*W*H):

-

depends

-

Weight:

-

6200 KG

-

Application:

-

Diamond Washing Equipment

-

Feeding size:

-

230mm

-

Power:

-

3-66Kw

-

Capacity:

-

5-300tons per hour

-

Screen size:

-

5-50mm

-

Hot selling Model:

-

JXSC-600,JXSC-900,JXSC-1500,JXSC-1800,JXSC-2100

-

Installation:

-

Field installation,General Arrangement,technical support,Online guide

-

Keywords:

-

Scrubber Trommel Wash Plant

-

Driving system:

-

advanced rubber tires driving

Product Description

|

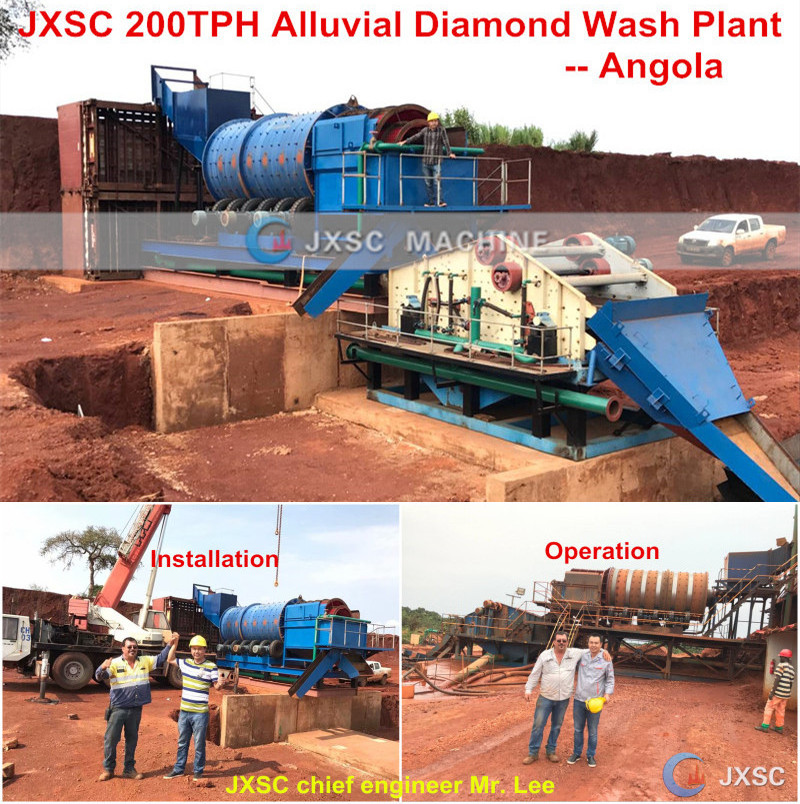

Eastman/JXSC Successful Cooperated Case -- 180-200TPH Diamond Mining Equipment

|

|

|

|

1.Customer’s nationality

|

Angola

|

|

|

2.Their interested model

|

Diamond Wash Plant

|

|

|

3.Application of the machine

|

After washing by trommel scrubber & screening by high-frequency vibrating screen, the next process is DMS.

|

|

|

4.Main requirements

|

(1) Capacity: 200-180 tons per hour

(2) Drum diameter: 2.2m, length 7m ( 5m scrubbing + 2m screen) (3) feed screen size at the hopper to be 230mm

(4) 2 layers PU screen, sieve mesh: 25mm, 2 mm

(5) Trommel inner lining material: Rubber inner liners

(6) The most advance speed reducer

(7) Transmission by rubber tires (8) With hopper and grizzly bar (9) With water spray system (10) With undersize slurry tank |

|

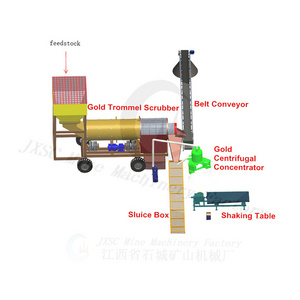

Trommel scrubber wash plant, Gold / Diamond mining equipment

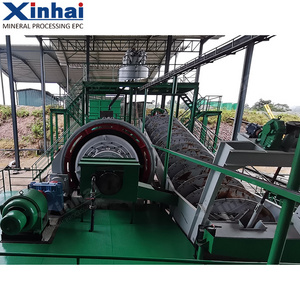

Trommel scrubber washer machine is main washing equipment in the mining industry, widely used for washing alluvial type/sand type ores and stones, that with much sticky clay, with much good washing effect for clay.

including two parts: drum scrubber and screen. The drum scrubber is for washing ore, the screen is for sieving different size particles after washing.

Different configuration of Trommel Scrubber Washer Machine can be customized:

1. Feeding hopper / grizzly hopper is available.

Trommel scrubber washer machine is main washing equipment in the mining industry, widely used for washing alluvial type/sand type ores and stones, that with much sticky clay, with much good washing effect for clay.

including two parts: drum scrubber and screen. The drum scrubber is for washing ore, the screen is for sieving different size particles after washing.

Different configuration of Trommel Scrubber Washer Machine can be customized:

1. Feeding hopper / grizzly hopper is available.

2. The washing drum, screening section diameter and length can be customized.

3. Drum inner lining material is both rubber liners & spiral steel plates available.

4. Driving system equip with durable rubber wheels.

5. The trommel can be fixed type, mobile type with rubber wheels, or skid mounted mobile type.

6. Water pump, water spray pipe, water distributor, diesel engine or generator available.

7. The screen sieve material can be high hardness manganese steel, stainless steel, or PU screen.

8. The screen layers can be 1, 2, or 3 layers.

Note: All the parts material are high end quality materials, the steel board is from Baosteel Group, the electric motor with IP56 water proof standard, the speed reducer from world famous brand K series.

3. Drum inner lining material is both rubber liners & spiral steel plates available.

4. Driving system equip with durable rubber wheels.

5. The trommel can be fixed type, mobile type with rubber wheels, or skid mounted mobile type.

6. Water pump, water spray pipe, water distributor, diesel engine or generator available.

7. The screen sieve material can be high hardness manganese steel, stainless steel, or PU screen.

8. The screen layers can be 1, 2, or 3 layers.

Note: All the parts material are high end quality materials, the steel board is from Baosteel Group, the electric motor with IP56 water proof standard, the speed reducer from world famous brand K series.

|

Model

|

Screen Size (MM)

|

Rotation Speed(R/Min)

|

Feeding size (mm)

|

Angle of inclination (degree)

|

Capacity (T/H)

|

Power (KW)

|

|

JXSC-400

|

≤20

|

27.9

|

≤80

|

≤10

|

1-5

|

3

|

|

JXSC-600

|

≤25

|

27.6

|

≤80

|

≤10

|

5-10

|

5

|

|

JXSC-750

|

≤25

|

27.6

|

≤100

|

≤10

|

10-30

|

7.5

|

|

JXSC-900

|

≤25

|

27.6

|

≤100

|

≤10

|

30-50

|

11

|

|

JXSC-1200

|

≤25

|

17

|

≤160

|

≤10

|

50-70

|

15

|

|

JXSC-1500

|

≤50

|

16

|

≤230

|

≤10

|

70-100

|

30

|

|

JXSC-1800

|

≤50

|

16

|

≤230

|

≤10

|

100-150

|

37

|

|

JXSC-2100

|

≤50

|

16

|

≤230

|

≤10

|

150-180

|

45

|

|

JXSC-2400

|

≤50

|

16

|

≤230

|

≤10

|

180-250

|

55

|

Diamond Process Flowchart

Eastman/JXSC Successful Cases

Packing&Shipping

Company Introduction

Ganzhou Eastman Technology Co, Ltd. (DN)

is a privatization enterprise,

we are a professional manufacturer of

Complete set Minerals Processing Machinery & Stone Crushers & Crushing Plant & pumps

since 1985

.

We aim at providing complete set processing equipments for Gold ore/ Tin ore/ Tungsten ore/ Iron ore/ Diamond/ Coltan ore / Silica sand / Zircon sand/ Black sand/Chrome ore, ect. As well as complete set stone crushing plant, varisous kinds water pump, sand slurry pumps, dredge pump and etc.

which focuses on mining equipment R&D, manufacturing and sales, the main products include all resires of stone crushers: jaw crusher, impact crusher, cone crusher, sand and stone making equipment, new type dry technology cement producing equipment, limestone producing equipment etc.

Besides, we also design and install sand project and ecological improvement equipment, and self-operate and agent import and export business for all kinds of products. The stone and sand making production process, mineral separation system, grinding system and drying system which independently R&D by our company have been the world leading level.

Related Products

Single-Cylinder Hydraulic Cone Crusher

Compound Cone Crusher

Multi-Cylinder Hydraulic Cone Crusher

Jaw Crusher

Impact Crusher

VSI Sand Maker

FAQ

●Pre-sales service:

We provide you with the prophase plan, process flow design and manufacturer equipment according to your special demand.

●Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

●After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every equipment before delivery.

●How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 40% deposit, 60% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

●Sales service: Send technicians to the site to guide the installation and commissioning, train the operators, and complete the acceptance with you.

●After-sales service: To establish long term friendship, we will regularly pay return visit to customers. Supplying technique, building design, instruction, installation and debugging for free.

●Lifelong service: One year warranty to make sure your machine runs constantly.Always offer lifelong service and provide spare parts for a long term.

●How is the quality of your products?

Answer: Our products are manufactured strictly according to national and international standard, and we will take a test on every equipment before delivery.

●How about the Guaranteed?

Answer: All of our products are guaranteed for one year. If products quality is not consistent with the description as we

described or the promise before you place order, we promise 100% refund.

●How about price?

Answer: For the complete same machine, we can promise our quality is the best when the price same as other competitors, and our price can be lowest when the quality at standard level.

●How about the service and payment terms?

Answer: We can accept T/T or other payment ways you request; 40% deposit, 60% balance before delivery, which is international trade practice; Finished product pictures will provide to customers before delivery.

Hot Searches