- Product Details

- {{item.text}}

Quick Details

-

Ultimate Strength (≥ MPa):

-

0.5

-

Density (kg/m³ ):

-

128

-

Length:

-

3000-15000mm

-

Working Temperature:

-

1260℃

-

Fiber Diameter:

-

2-3μm

-

Shrinkage (1800 ℉, 3h):

-

-3

-

Thermal Conductivity:

-

0.055-0.18

-

Model Number:

-

XWT

-

Brand Name:

-

HONGDA

-

Place of Origin:

-

Henan, China

-

Product name:

-

ceramic cotton

-

Color:

-

Pure white

-

Package:

-

Carton+Pallet

-

Density:

-

96-128kg/m3

-

Classification temperature:

-

1050/1260/1350/1430

-

Working Temp:

-

1100~1350 degree Celsius

-

Feature:

-

Low Thermal Conductivity

-

AL2O3:

-

47-49%

-

AL2O3+SiO2:

-

88.5-99.8%

-

Raw material:

-

Ceramic Fiber Bulk

Quick Details

-

Thickness:

-

10-50mm

-

Width:

-

610-1220mm

-

Chemical Composition:

-

Al2O3+SIO2

-

Ultimate Strength (≥ MPa):

-

0.5

-

Density (kg/m³ ):

-

128

-

Length:

-

3000-15000mm

-

Working Temperature:

-

1260℃

-

Fiber Diameter:

-

2-3μm

-

Shrinkage (1800 ℉, 3h):

-

-3

-

Thermal Conductivity:

-

0.055-0.18

-

Model Number:

-

XWT

-

Brand Name:

-

HONGDA

-

Place of Origin:

-

Henan, China

-

Product name:

-

ceramic cotton

-

Color:

-

Pure white

-

Package:

-

Carton+Pallet

-

Density:

-

96-128kg/m3

-

Classification temperature:

-

1050/1260/1350/1430

-

Working Temp:

-

1100~1350 degree Celsius

-

Feature:

-

Low Thermal Conductivity

-

AL2O3:

-

47-49%

-

AL2O3+SiO2:

-

88.5-99.8%

-

Raw material:

-

Ceramic Fiber Bulk

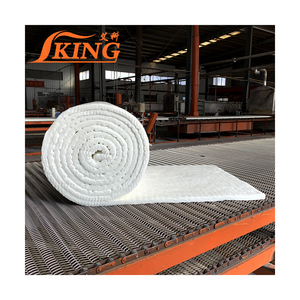

ceramic wool furnace insulation good price aluminium silicate fiber ceramic cotton

ceramic cotton is composed of long, flexible, interwoven fibers yielding a strong, lightweight, yet durable, blanket for applications in a temperature range from 538°C (1000°F) to 1480°C (2696°F).

ceramic cotton has the heat resistance of a hard refractory which gives it outstanding insulation value and is an effective solution for a variety of heat processing applications. They are easy to install, require no curing or dry out time. Rapid heat up can be achieved with all Ceramic Fiber blankets; they will not crack or spall and are thermal shock resistant. This product saves energy. It reduces heat loss and heat storage versus other hard refractory products.

Product Detail ceramic wool furnace insulation good price aluminium silicate fiber

|

Seven Advantages |

01. Low thermal conductivity, low thermal capacity 02. good tensile strength, good layering resistance 03. excellent thermal stability, heat insulation and fire prevention 04. sound insulation and sound-absorbing, 06. uniform fiber diameter, manufacturers direct sales, 07. easy cutting and installation, convenient construction |

Product Index

Fireproof Blanket |

||||||

| Type | Common | Standard | High Purity | High Aluminium | Zirconia | |

| Maximum temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1430 | |

| Working Temperature (°C) | <1000 | 1050 | 1100 | 1200 | 1200 | |

| Color | white | spotlessly white | spotlessly white | spotlessly white | spotlessly white | |

| Density (kg/m3) | 96/128 | 96/128 | 96/128 | 96/128 | 96/128 | |

| Shrinkage on heating (%) (24hours,density as 128/m3) | -4 (1000°C) | -3 (1000°C) | -3 (1100°C) | -3 (1250°C) | -3 (1350°C) | |

| Thermal conductivity by different temperature (w/m.k) (density as 128kg/m3) |

0.09(400°C)

0.16(800°C) |

0.09(400°C)

0.16(800°C) |

0.09(400°C)

0.20(1000°C) |

0.12(600°C)

0.20(1000°C) |

0.16(800°C)

0.20(1000°C) |

|

| Tensile strength (MPa) (density as 128kg/m3) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

| Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

| AL2O3+SiO2 | - | - | - | - | 99 | |

| ZrO2 | - | - | - | - | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+k2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

| Size ( mm) |

L*W*T:14640/7200/3600*1220/610*10/20/30/40/50mm

(Other sizes and shapes on request)

|

|||||

With the company healthy and fast development, our ceramic cotton products had been sold to all over the country, as far as Vietnam, India, Pakistan, kazakhstan and other southeast Asian countries and regions.

|

Fireproof Blanket Application |

1. High temperature insulation materials in spaceflight, steel and Petrifaction industry. 2. Fire resistance and insulation in military equipment. 3. Repair, Insulation & Linings for Furnaces, Kilns, Generators, Reformers, Boilers, etc. 4. Insulation for Steam & Gas Turbines, & Other High Temperature Equipment Insulation for Nuclear Applications & Power Plants. 5. High-Temperature Pipe Insulation & Filtration, Casting Mold Insulation, etc. 6. High-Temperature Seals , Furnace Door Seals, Expansion Joint Seals. 7. Fire Protective Insulation or Linings. |

ceramic cotton Package Arrangment

1. woven bag

2. carton box outside ceramic wool furnace insulation good price aluminium silicate fiber