- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

BCJ203

-

Product name:

-

Customize Design Pvc Great Wall Panel Extrusion Mould

-

Heating plates:

-

Cast-aluminium

-

Die Head:

-

2Cr13 mould steel,can be 3Cr13 or 3Cr17 mould steel or negotiable

-

Calibrator:

-

3Cr17 mould steel,can be 2Cr13 or 3Cr13 mould steel or negotiable

-

Water tank:

-

Siamesed,stainless steel semi-packed, or vacuum vortex

-

Surface treatment:

-

Mrror-polished

-

Accessories:

-

removable location pins, detachable thread insert, ect

-

Design software:

-

CAD

-

Function:

-

Mould-Proof

-

Application:

-

Household Product Mold

Quick Details

-

Shaping Mode:

-

Extrusion Mould

-

Place of Origin:

-

China

-

Brand Name:

-

Bossyin

-

Model Number:

-

BCJ203

-

Product name:

-

Customize Design Pvc Great Wall Panel Extrusion Mould

-

Heating plates:

-

Cast-aluminium

-

Die Head:

-

2Cr13 mould steel,can be 3Cr13 or 3Cr17 mould steel or negotiable

-

Calibrator:

-

3Cr17 mould steel,can be 2Cr13 or 3Cr13 mould steel or negotiable

-

Water tank:

-

Siamesed,stainless steel semi-packed, or vacuum vortex

-

Surface treatment:

-

Mrror-polished

-

Accessories:

-

removable location pins, detachable thread insert, ect

-

Design software:

-

CAD

-

Function:

-

Mould-Proof

-

Application:

-

Household Product Mold

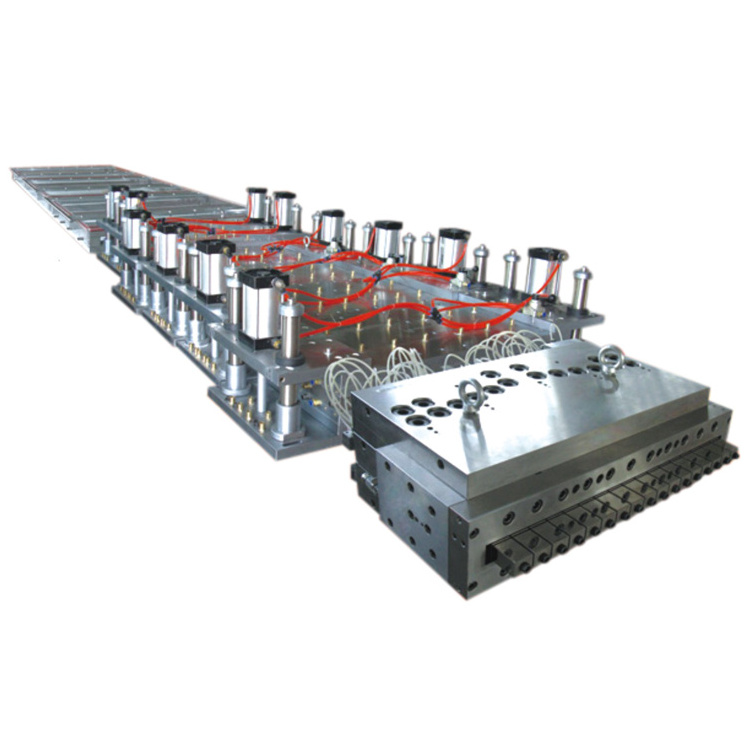

Customized WPC Plastic Extrusion Profile Mold

| Descriptions: |

Customize Design Pvc Great Wall Panel Extrusion Mould

|

| Mould material | 2Cr13,3Cr17, 3Cr13 as per your request |

| Mould cavity | 1 or multi-cavity |

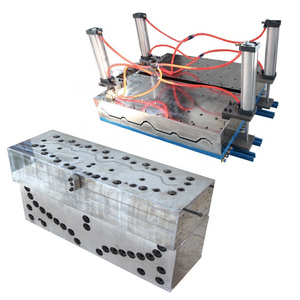

| Mould composition | Die head, calibrators and water tank |

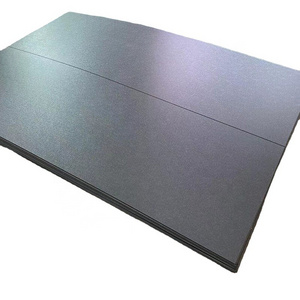

| Selectable raw materials | PVC, PP, PE,WPC, UPVC |

| Selectable technology | low-foaming, high-foaming & substance co-extrusion |

| Die Dimension | 60 to 1000mm AS your demands |

| Available thickness | 0.6-1.8mm AS your demands |

| Die type | Hollow die &Solid die |

| Way Of Heating |

Electric heating

|

| Features: | 1 length: Customized for plastic extrusion die |

| 2 Thickness: Customized for plastic extrusion die | |

| 3 HS code : 8480790090 | |

| 4 After-sales Service : Engineers available to service overseas |

Detailed Product Description :

1.Advanced mirror polished surface treatment technology.

2.High quality 3Cr17 stainless steel material for wood plastic extrusion mould.

3.Configuration:one die head + four heating plates+three-segment calibrator +two-meter stainless water tank or as you require.

1. Using the overall flowing path core support structure

2. Using the removable locating pin devices;

3. The channel design has avoided the dead area and retention

4. The optimized design of the flowing channel gives it a stronger impact resistance .

5. The inside and outside surface of the profile is smooth and without scratches

6.Easy to assemble and disassemble.

7. The mould has high stability and high extrusion speed

Package as below picture shows:

What we can supply ?

We can supply you with the plastic extrusion mould as follows:

Kinds of extrusion mould

1. Mould for upvc profiles

Application:

casement door and window; sliding door and window; blinds , tilt turn window; color co-ex. Window and door; handrail; trunk pipe and so on.

2. Mould for PE WPC and PP WPC

Application:

Landscape, summer house, handrail, decking profile, grape trellis, industrial pallets, cabinet plates,etc.

3. Mould for PVC and foaming products

Application:

door panel, decoration board, foaming board and furniture board and so on.

What 's the most important part of a set?

Die

- Designed by different formulations and chemical melt flow characteristics

- Multi-cavity with material supplied to each cavity respectively,Smooth of flowing channel

- Integated mandrel structure, Mirror polishing

Calibrator

- High efficient and even cooling system

- A number of patented brightening technology

- The perfect combination of precise positioning and reliable shape

Water tank

- Spraying and immersing cooling system

- Vacuum rotating water tank assisted positioning

How about Application?

How about Company?

Business throughout the country provinces and exported to Japan, Egypt,India, Russia, South Korea and other countries, deeply domestic and foreign customers trust and praise.

Q1 : How about quality control in our company and delivery time?

A1 : Every piece of goods is tested strictly before packing and delivery. Generally, it take 45 days. It depends on the mold’s size and complexity.

Q2 : How to receive an quotation in the shortest time?

A2 : Such as quantity, cavity, sample etc. You can provide us a sample, we will help finish the 2D drawing design.

Q3 : How to ensure the products' quality before shipment?

A3 : We will supply picture or send you videos to show the production process,or your agent come

to see the test.

Q4 : What's your payment terms ?

A4 : By T/T 40% deposit in advance, balance 60% before shipment.

Q5 : Can I get discounts?

A5:Yes. Old customer and frequent customers, we give reasonable discounts.

Q6 : After-sales Service ?

A6 : We have 3 Engineers available to service overseas priority.