- Product Details

- {{item.text}}

Quick Details

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUILONG

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

1580*1100*2100mm

-

Weight (KG):

-

3000 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Block Type:

-

Aerated Autoclaved Concrete Block

-

Capacity:

-

30000-300000m3/Year

-

Cutting Machine Size:

-

2m, 4.2m, 4.8m, 6m

Quick Details

-

Type:

-

Autoclaved aerated concrete block (AAC)

-

Brick Raw Material:

-

Cement

-

Production Capacity (Pieces/8 hours):

-

4480 pcs/8hours, 2500 pcs/8hours, 3400 pcs/8hours, 1920 pcs/8hours, 5760 pcs/8hours, 1500 pcs/8hours, 1280 pcs/8hours, 3000 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours, 2560 pcs/8hours, 1000 pcs/8hours, 800 pcs/8hours

-

Brick size:

-

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 150*150*100 mm, 400*200*200 mm, 230*220*115 mm, Other

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HUILONG

-

Voltage:

-

220V or 380V

-

Dimension(L*W*H):

-

1580*1100*2100mm

-

Weight (KG):

-

3000 kg

-

Raw material:

-

Fly Ash Cement Sand Concrete

-

After-sales Service Provided:

-

Service Machinery Overseas

-

Block Type:

-

Aerated Autoclaved Concrete Block

-

Capacity:

-

30000-300000m3/Year

-

Cutting Machine Size:

-

2m, 4.2m, 4.8m, 6m

Basic Info

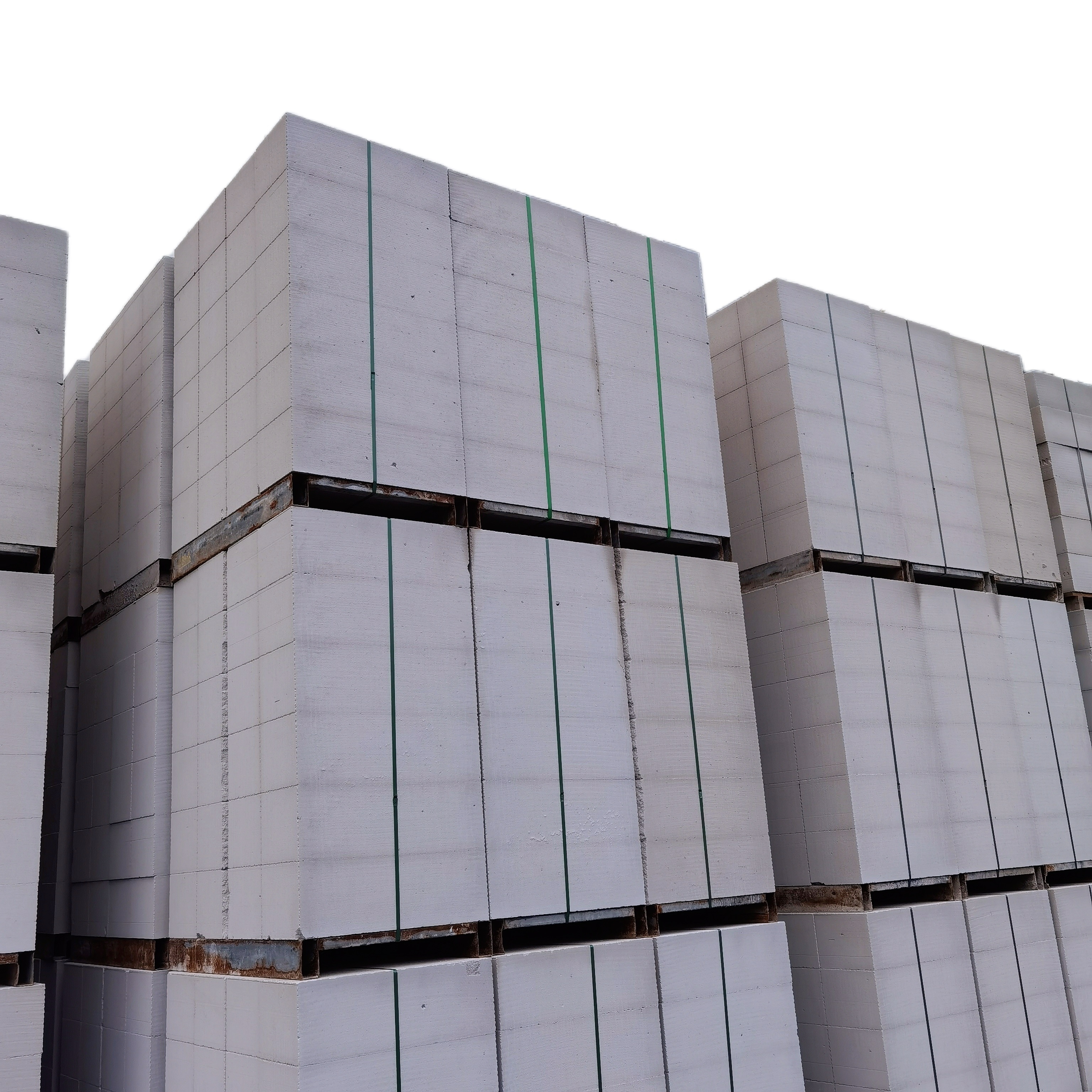

AAC (Autoclaved aerated concrete) block Main raw materials of AAC are siliceous material (sand, fly ash and Silicon tailings) and Calcium materials (lime and cement) mixed with foaming agent (aluminum powder). It is the product of light porous silicate through the following processes: batching, mixing, pouring, hardening, cutting, autoclaving and curing etc. Because of large amount of well-distributed tiny pores after foaming, it is named autoclaved aerated concrete.

Based on the shape of AAC products, it can be divided into: AAC blocks and AAC panels

. It is a revolutionary material offering an unique combination of high durability and strength, low weight, excellent heat insulation, fire resistant, noise absorption, unprecedented build ability and superior ecological green features.

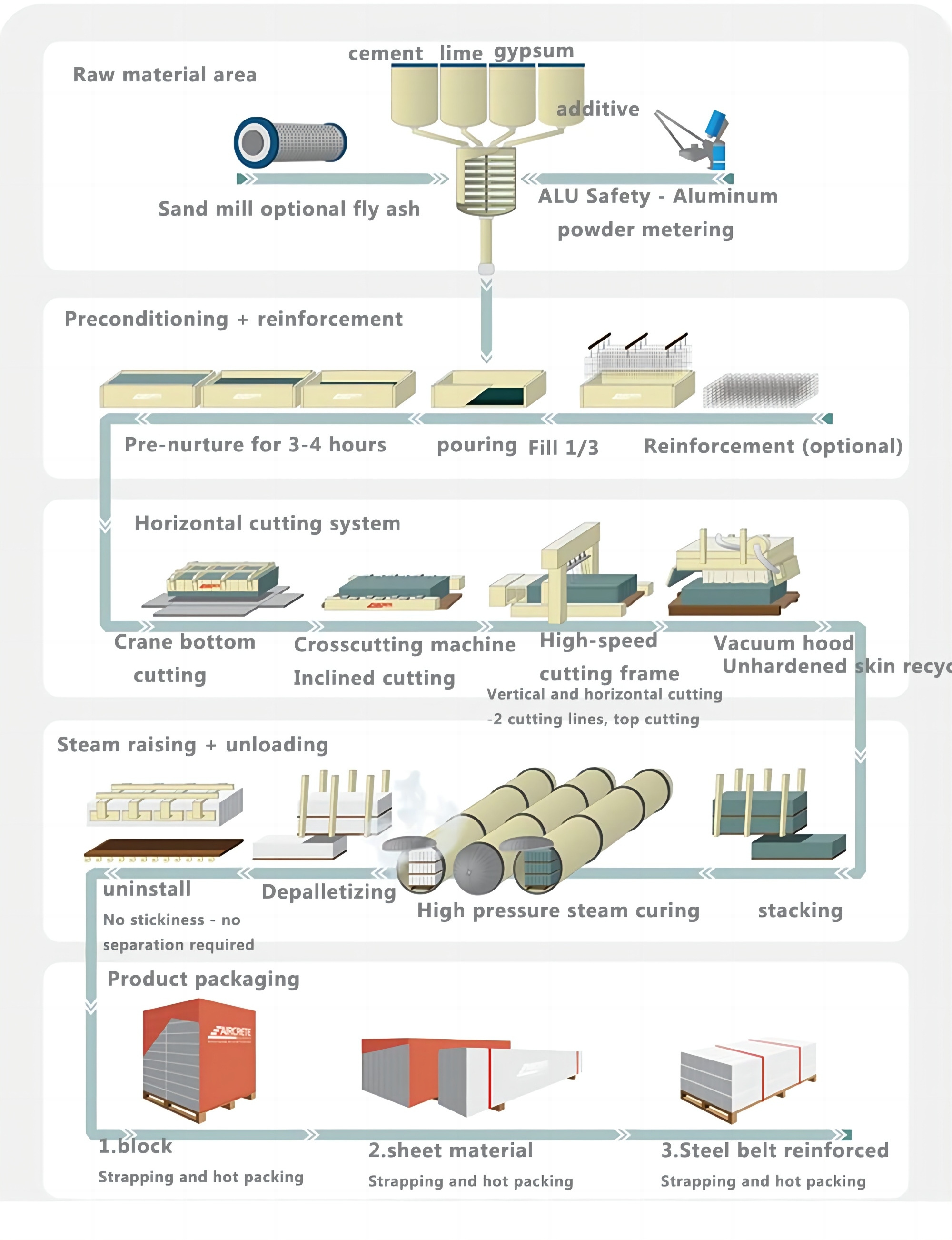

Production Process

HUILONG supply full set of AAC production line, including plant design, automation design and all machines such as cutting machine, milling ball, mould, autoclaves, turnover machine, etc. The automatic production line can make AAC Panels and AAC Blocks with production capacity from 100,000CBM to 60,000CBM per year.

The AAC

production line

is simpler and quicker than traditional methods. There are patents of Germany and Sweden and Japan included in the production equipments.

Size

|

ITEM

|

AAC-5

|

AAC-10

|

AAC-15

|

AAC-20

|

AAC-30

|

|

Capacity m3/year

|

50000

|

100000

|

150000

|

200000

|

300000

|

|

Cake Size

m3 |

4.2x1.2x0.6

|

4.2x1.2x0.6

|

4.2x1.2x0.6

|

4.8x1.2x0.6

|

4.8x1.2x0.6

|

|

Installation Power, kw

|

300

|

600

|

600

|

900

|

1200

|

|

Production Cycle, mould/min

|

5

|

6

|

6

|

6

|

6

|

|

Workshop Area,m2

|

3000

|

3000

|

3500

|

4000

|

5000

|

|

Plant Area,m3

|

20000

|

20000

|

25000

|

30000

|

35000

|

Application

Product Packaging

Hot Searches