B: The production raw material is soap particles

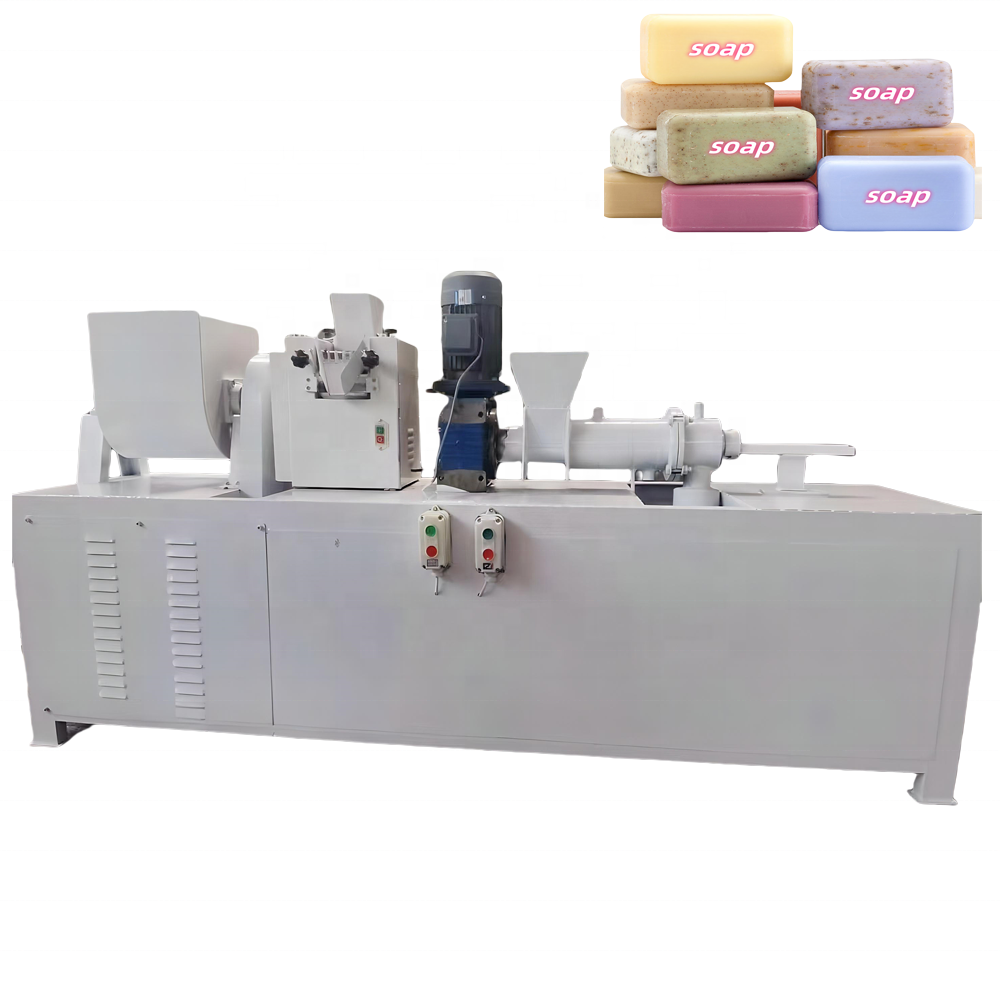

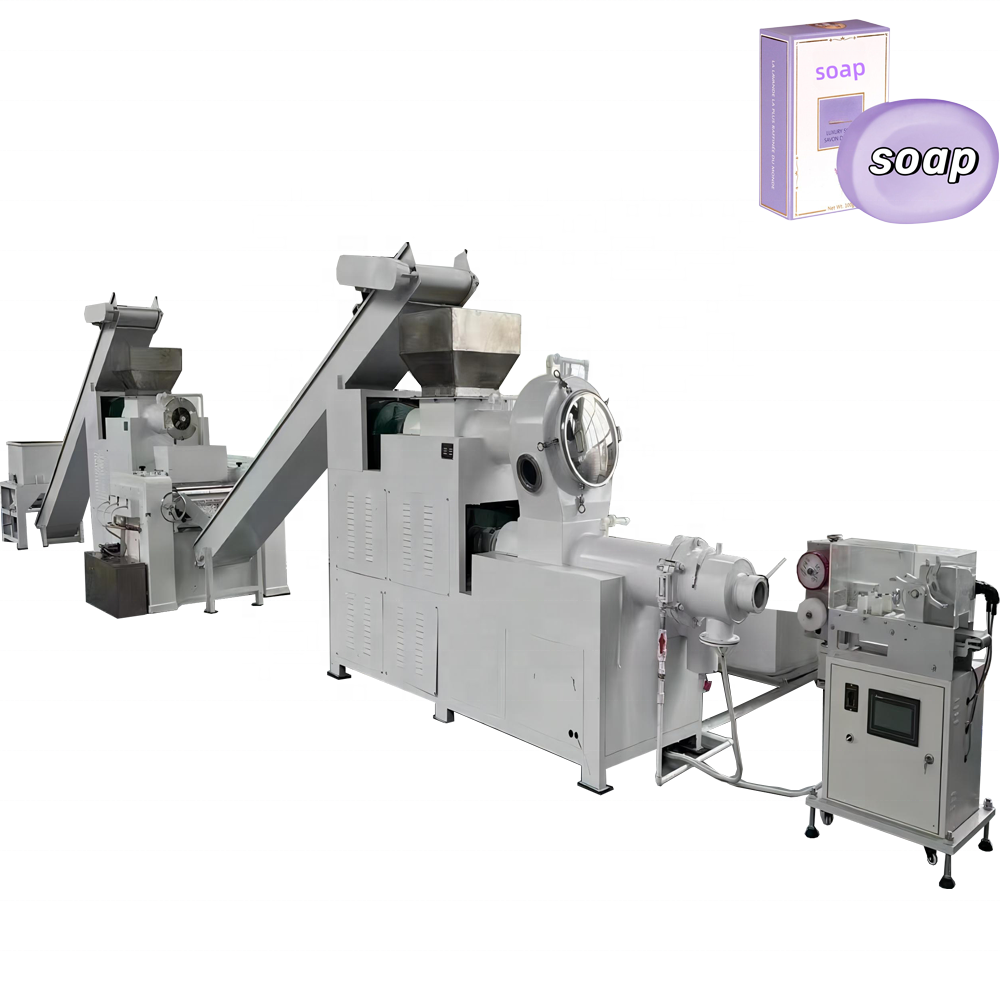

Basic process is to put the soap blocks into the fully automated finishing production line, including mixer, three roller mills, vacuum p

lodder

, and cutting machine.

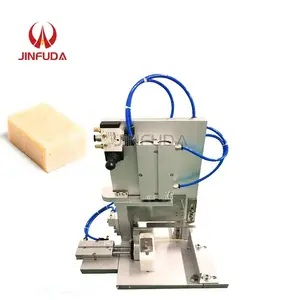

The dimension and pattern of the soap can be made by customer's requirements.