characteristics in high speed, low noise and high precision, they are also of 3 times service life than Z94-C series.

the machines stop automatically to prevent abrasive wear.

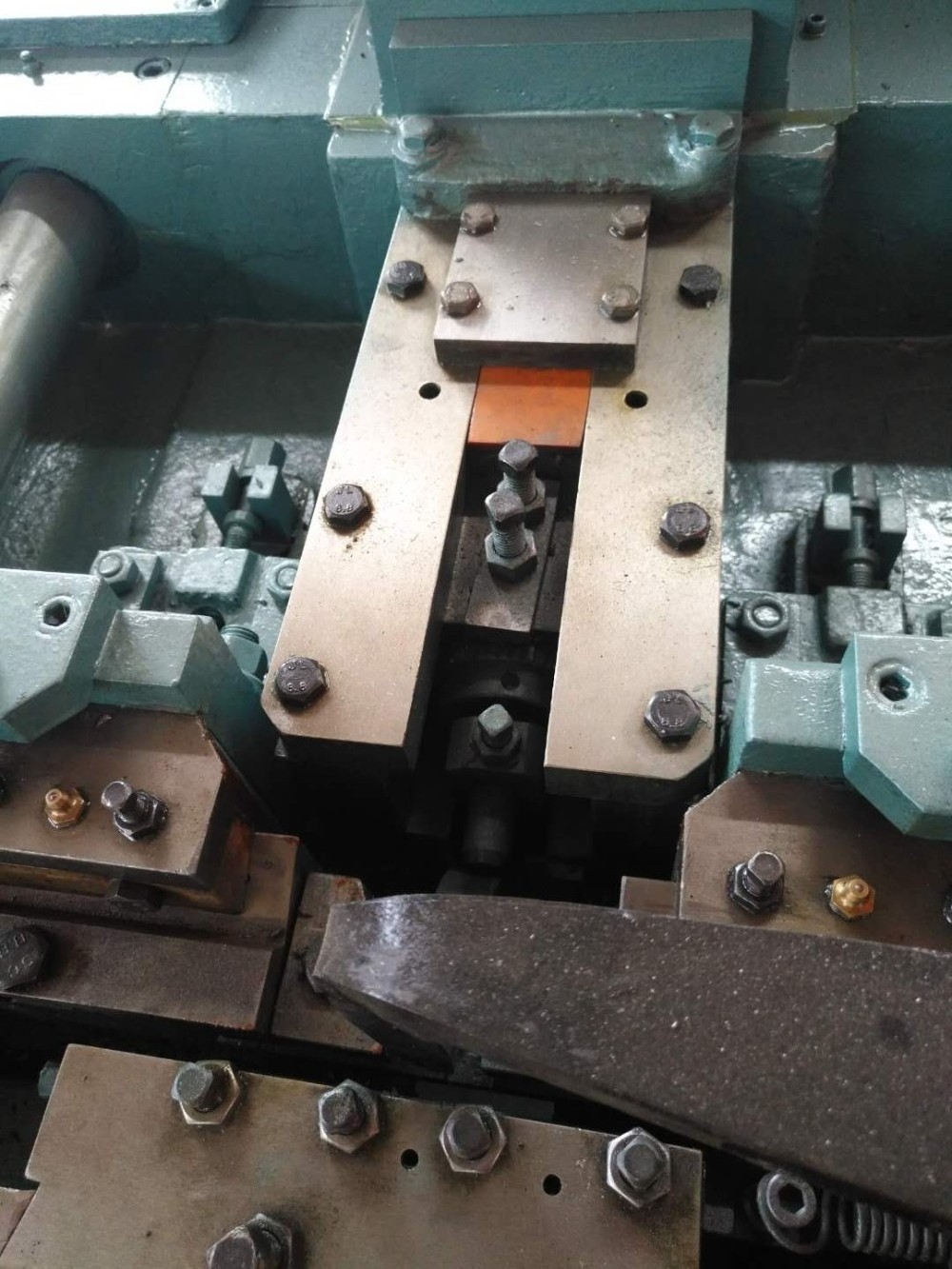

The rolling part of the machines applies the combination of bush bearing rolling and bearing rolling, which enhances the size stability of nail heads' formation and brings convenience to the maintenance of the machines. The main parts of the machines are made of high -quality steel, such as crankshaft, sliding block of heading device made of 40CrNiMo, drive bevel gear made of 20CrMoti and all heat treated, making the machines impact resistant, wear resistant and durable.

|

TECHNICAL SPECIFICATIONS

|

|

|

|

|||

|

Model

|

Unit

|

Z94-4.5H

|

Z94-3.4H

|

|||

|

Max. dia. Of nail

|

mm

|

4.5

|

3.7

|

|||

|

Min. dia. Of nail

|

mm

|

2.8

|

1.8

|

|||

|

Max. length of nail

|

mm

|

100

|

80

|

|||

|

Min. length of nail

|

mm

|

50

|

20

|

|||

|

Designed capacity

|

pcs/min

|

300

|

350

|

|||

|

Motor power

|

KW

|

4

|

3

|

|||

|

Weight

|

kg

|

3800

|

1800

|

|||

|

Overall dimensions(L*W*H)

|

mm

|

3000*1600*1650

|

2400*1500*1500

|

|||

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.