- Product Details

- {{item.text}}

Quick Details

-

Keyword:

-

TV Evaporator

-

COLOR:

-

White/Gray/Black/Blue

-

Appliance:

-

Home, industry

-

Material:

-

Aluminum/aluminum alloy

-

Packing:

-

Wooden Box/carton

-

Tube material:

-

copper

-

Cooling System:

-

R134A

-

Thickness:

-

1.1-1.2mm

-

Surface:

-

e-coacting

-

Function:

-

Cool

Quick Details

-

Type:

-

Evaporator

-

Application:

-

Refrigeration Parts

-

Place of Origin:

-

Zhejiang, China

-

Keyword:

-

TV Evaporator

-

COLOR:

-

White/Gray/Black/Blue

-

Appliance:

-

Home, industry

-

Material:

-

Aluminum/aluminum alloy

-

Packing:

-

Wooden Box/carton

-

Tube material:

-

copper

-

Cooling System:

-

R134A

-

Thickness:

-

1.1-1.2mm

-

Surface:

-

e-coacting

-

Function:

-

Cool

Application: refrigeration parts

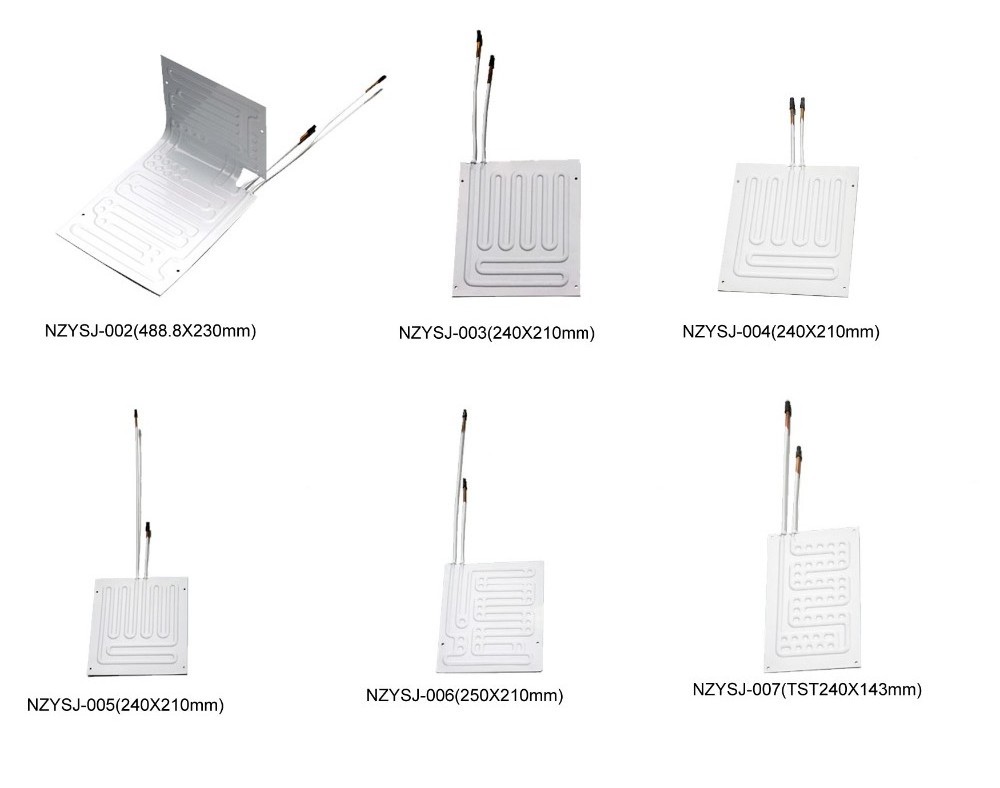

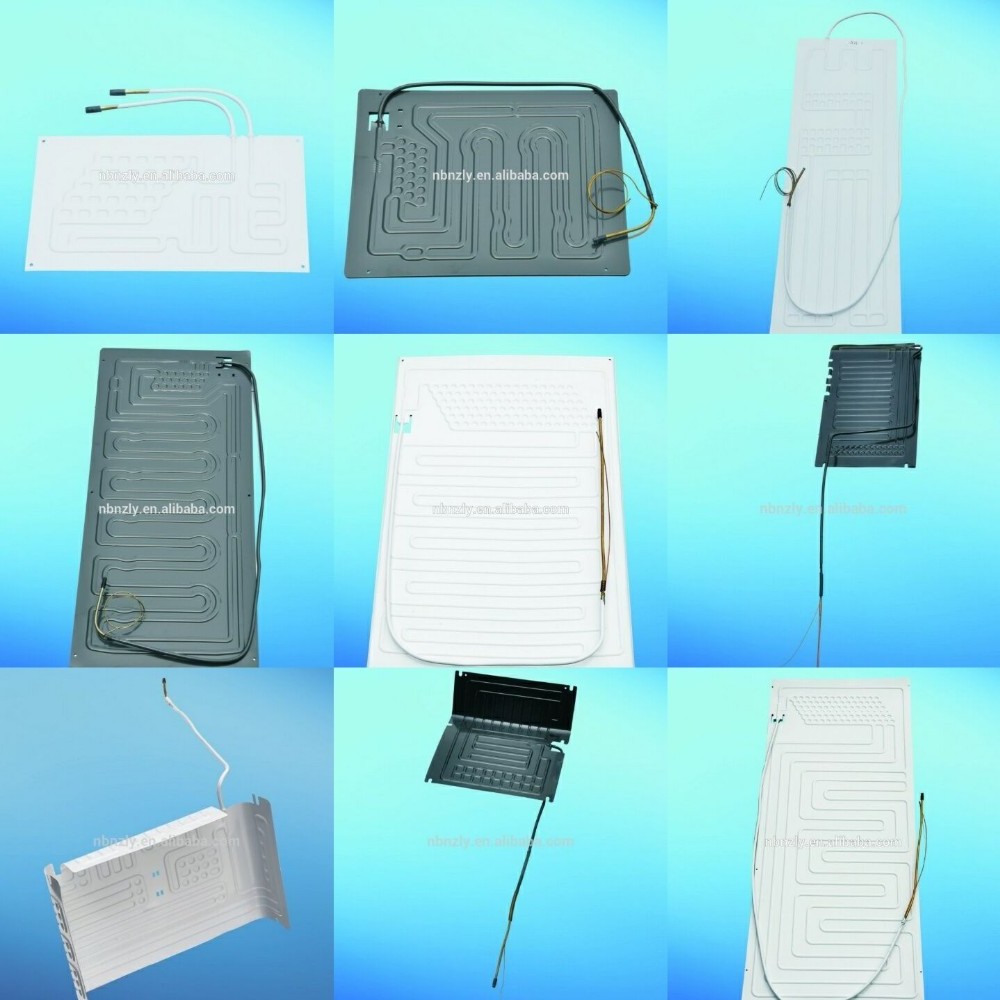

Structure: Double side,Single side and Part single side roll bond evaporator

Application: refrigeration parts

Raw materials (Al plate)

1.Al plate: the thickness of finished product is 1.1-2.0mm

2.the thickness of raw Al plate:1.7-3mm

key process:

preparing materials – cleaning – printing – rolling – annealing - blowing up – punching –folding and sharpening –adding the capillary – assemble welding – leakage testing – cleaning and drying – coating - inspection – packing.

Max dimension: width 700mm, length 1800mm.

We can produce according to your requirement.

Structure:

Double side roll bond evaporator

Single side roll bond evaporator

Part single side roll bond evaporator.

Performance:

Surface is treated with powder painting to prevent the corrosion.

Inner cleanness can meet the requirement of R134a&CFC cooling system.

Can satisfy the cooling capability.

Technical Data Details

|

Raw material (Al plate) |

Al plate: the thickness of finished product is 1.1-2.0mm | |||

| The thickness of raw Al plate:1.7-2.15mm | ||||

|

|

refrigeration parts | |||

|

Structure |

Double side roll bond evaporator | |||

| Single side roll bond evaporator | ||||

| Part single side roll bond evaporator | ||||

|

Key process |

preparing materials – cleaning – printing – rolling – annealing - blowing up – punching –folding and sharpening –adding the capillary – assemble welding – leakage testing – cleaning and drying – coating - inspection – packing. | |||

|

Performance

|

(1) Surface treated with powder coating to prevent corrosion | |||

| (2) Inner cleanness can meet the requirement of R134a and CFC cooling system | ||||

| (3) Can satisfy the cooling capability requirements of the designed refrigerator. | ||||

| Notation | Max dimension: width 292mm, length 1277.5mm. | |||