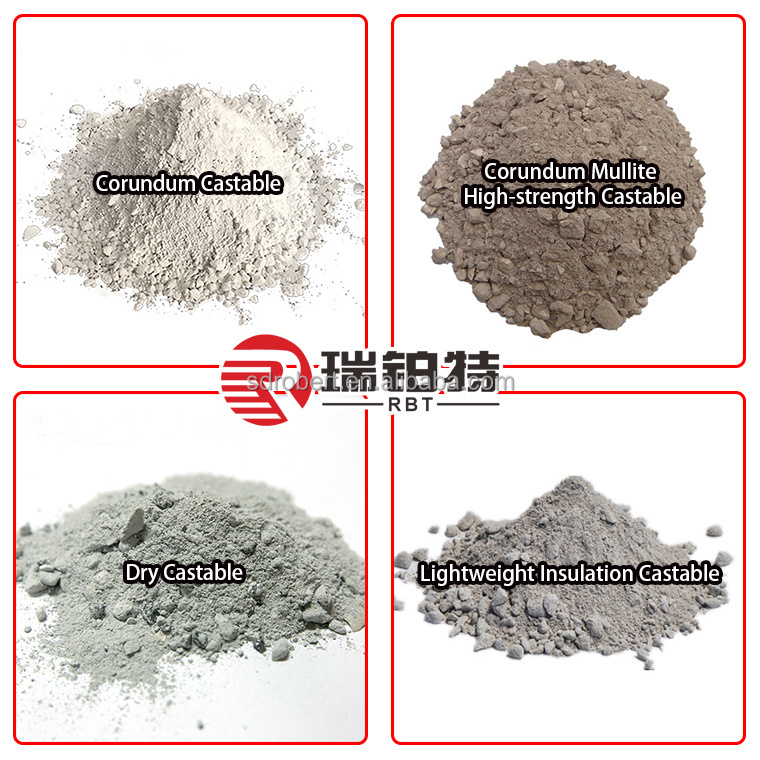

- Product Details

- {{item.text}}

Quick Details

-

CaO Content (%):

-

1.5%-5%

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

Low Cement/High Strength/Lightweight

-

Brand Name:

-

Robert

-

HS Code:

-

38160020

-

Sample:

-

Available

-

Shipping Port:

-

Qingdao/Tianjin/Shanghai

-

Application:

-

Furnace

-

Raw Material:

-

Clay/Bauxite/Mullite/Corundum/Silicon Carbide, etc.

-

Package:

-

25/50KG Bag

-

Certificate:

-

ISO/MSDS

-

Size:

-

0-5mm

-

Quantity:

-

24MTS/20`FCL

-

Product Name:

-

Refractory Castable&Concrete

Quick Details

-

SiO2 Content (%):

-

8%-55%

-

Al2O3 Content (%):

-

42%-90%

-

MgO Content (%):

-

0.02%-0.05%

-

CaO Content (%):

-

1.5%-5%

-

CrO Content (%):

-

0.002%

-

SiC Content (%):

-

0

-

Place of Origin:

-

Shandong, China

-

Model Number:

-

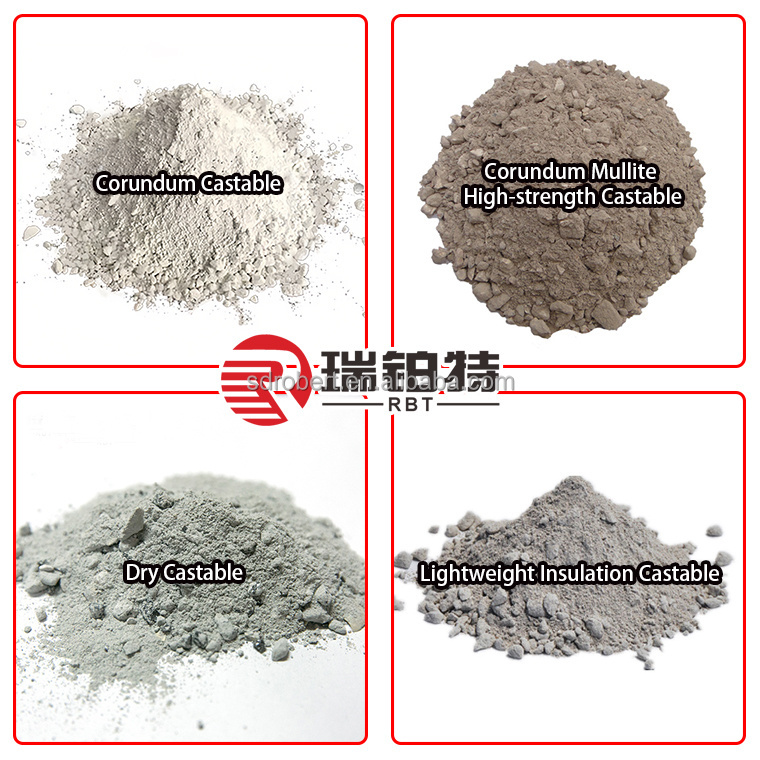

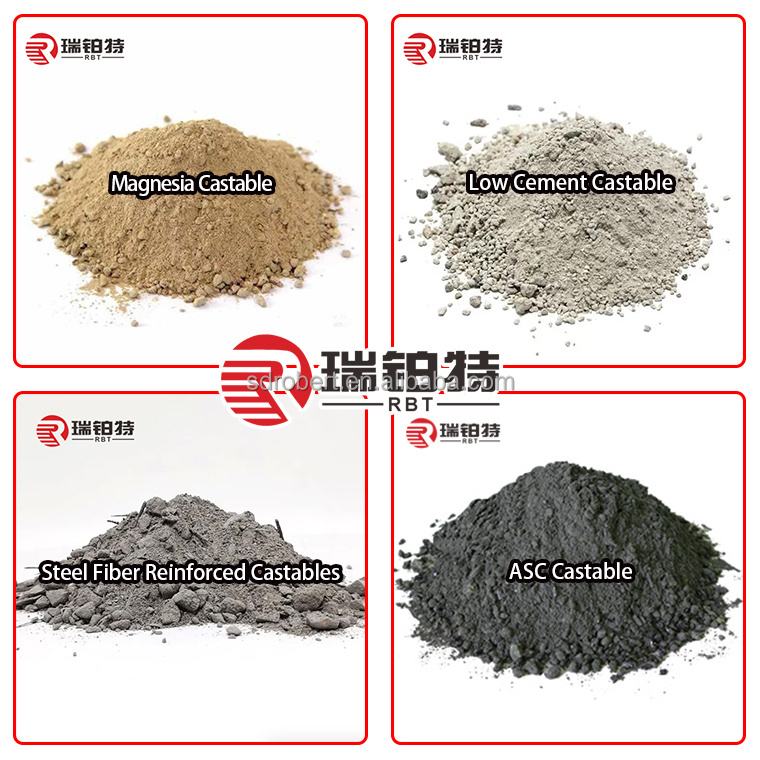

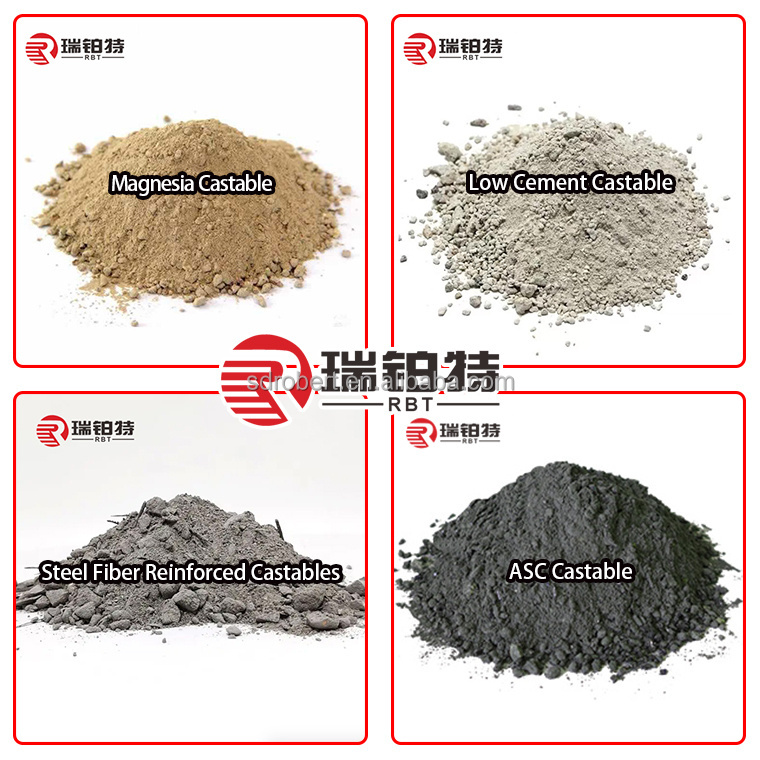

Low Cement/High Strength/Lightweight

-

Brand Name:

-

Robert

-

HS Code:

-

38160020

-

Sample:

-

Available

-

Shipping Port:

-

Qingdao/Tianjin/Shanghai

-

Application:

-

Furnace

-

Raw Material:

-

Clay/Bauxite/Mullite/Corundum/Silicon Carbide, etc.

-

Package:

-

25/50KG Bag

-

Certificate:

-

ISO/MSDS

-

Size:

-

0-5mm

-

Quantity:

-

24MTS/20`FCL

-

Product Name:

-

Refractory Castable&Concrete

|

Product Name

|

Refractory Castable/Refractory Concrete

|

|

Categories

|

Low Cement/High Strength/

Light Weight

|

|

Features

|

1. Easy construction

2. Good slag resistance

3. Good corrosion resistance

4. Good fire resistance

5. Energy saving and environmental protection

|

Product Description

|

Product

|

Low Cement Castable

|

High Strength Castable

|

|

Description

|

Low cement castables refer to new castables with very little cement binder. The cement content of refractory castables is

generally 15% to 20%, and the cement content of low cement castables is about 5%, and some are even reduced to 1% to 2%.

|

High strength wear-resistant castable is composed of high strength aggregate, mineral admixtures, high strength aggregate and anti

crack and wear-resistant agent.

|

|

Features

|

Thermal shock resistance, slag resistance, and erosion resistance are significantly improved, surpassing similar refractory

bricks.

|

High strength, high wear resistance, impact resistance, erosion resistance, anti-oil permeability, arbitrary shape control, strong integrity, simple construction, good construction performance, and long service.

|

|

Applications

|

1.Lining of various heat treatment furnaces, heating furnaces, shaft kilns, rotary kilns, electric furnace covers, blast furnace tapholes;

2.Self-flowing low-cement castables are suitable for high-temperature spray gun linings for spray metallurgy and petrochemical catalytic cracking reactors Wear-resistant lining, outer lining of heating furnace water-cooled pipe, etc.

|

Lining wear-resistant layer of slag sluice,

ore trough, coal spout, hopper and silo in metallurgy, coal, thermal power, chemical,

cement and other industries, and the blast furnace mixing silo, sintering silo, feeder, pelletizer, etc.

|

|

Product

|

High Alumina Castable

|

Lightweight Castable

|

|

Description

|

High alumina castables are refractory

castables made of high-alumina raw materials

as aggregates and powders, and added

with binders.

|

The lightweight castable with low bulk density is made of aluminate cement, high alumina fine material, ceramsite, and additives.

|

|

Features

|

Has high mechanical strength and good thermal shock resistance, abrasion resistance and other properties

|

Low bulk density, small thermal conductivity, good thermal insulation effect, high compressive strength, acid and acid gas

corrosion resistance, heat insulation, thermal insulation, and low water absorption.

|

|

Applications

|

It is mainly used as the inner lining of boilers, blast furnace hot blast stoves, heating furnaces, ceramic kilns and other kilns.

|

The lightweight castable can be used for the thermal insulation layer of high-temperature industrial furnace and equipment also

used for the lining of various high-temperature gas pipe.

|

Details Images

Product Index

|

Product Name

|

|

Low Cement Castable

|

|

|

|

|

|||||

|

INDEX

|

|

RBTZJ-42

|

RBTZJ-60

|

RBTZJ-65

|

RBTZJS-65

|

RBTZJ-70

|

|||||

|

Working Limit Temperature

|

|

1300

|

1350

|

1400

|

1400

|

1450

|

|||||

|

Bulk Density(g/cm3)

110℃×24h≥

|

|

2.15

|

2.3

|

2.4

|

2.4

|

2.45

|

|||||

|

Cold Bending Strength

110℃×24h(MPa) ≥

|

|

4

|

5

|

6

|

6

|

7

|

|||||

|

Cold Crushing Strength(MPa) ≥

|

110℃×24h

|

25

|

30

|

35

|

35

|

40

|

|||||

|

|

CT℃×3h

|

50

1300℃×3h

|

55

1350℃×3h

|

60

1400℃×3h

|

40

1400℃×3h

|

70

1400℃×3h

|

|||||

|

Permanent Linear Change

@CT℃ × 3h(%)

|

|

-0.5~+0.5

1300℃

|

-0.5~+0.5

1350℃

|

0~+0.8

1400℃

|

0~+0.8

1400℃

|

0~+1.0

1400℃

|

|||||

|

Thermal Shock Resistance

(1000℃water) ≥

|

|

―

|

―

|

―

|

20

|

―

|

|||||

|

Al2O3(%) ≥

|

|

42

|

60

|

65

|

65

|

70

|

|||||

|

CaO(%) ≤

|

|

2-3

|

2-3

|

2-3

|

2-3

|

2-3

|

|||||

|

Fe2O3(%) ≤

|

|

2.0

|

1.5

|

1.5

|

1.5

|

1.5

|

|||||

|

Product Name

|

|

High Strength Castable

|

|

|

|

|

|||||

|

INDEX

|

|

HS-50

|

HS-60

|

HS-70

|

HS-80

|

HS-90

|

|||||

|

Working Limit Temperature(℃)

|

|

1400

|

1500

|

1600

|

1700

|

1800

|

|||||

|

110℃ Bulk Density(g/cm3) ≥

|

|

2.15

|

2.30

|

2.40

|

2.50

|

2.90

|

|||||

|

Modulus of Rupture

(MPa) ≥

|

110℃×24h

|

6

|

8

|

8

|

8.5

|

10

|

|||||

|

|

1100℃×3h

|

8

|

8.5

|

8.5

|

9

|

9.5

|

|||||

|

|

1400℃×3h

|

8.5 1300℃×3h

|

9

|

9.5

|

10

|

15

|

|||||

|

Cold Crushing Strength(MPa)≥

|

110℃×24h

|

35

|

40

|

40

|

45

|

60

|

|||||

|

|

1100℃×3h

|

40

|

50

|

45

|

50

|

70

|

|||||

|

|

1400℃×3h

|

45 1300℃×3h

|

55

|

50

|

55

|

100

|

|||||

|

Permanent Linear Change(%)

|

1100℃×3h

|

-0.2

|

-0.2

|

-0.25

|

-0.15

|

-0.1

|

|||||

|

|

1400℃×3h

|

-0.45 1300℃×3h

|

-0.4

|

-0.3

|

-0.3

|

-0.1

|

|||||

|

Al2O3(%) ≥

|

48

|

48

|

55

|

65

|

75

|

90

|

|||||

|

CaO(%) ≤

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

4.0

|

|||||

|

Fe2O3(%) ≤

|

3.5

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

|||||

|

Product Name

|

|

High Alumina Castable

|

|

|

|

|

|

||||||

|

INDEX

|

|

Al2O3

(%) ≥

|

CaO

(%) ≥

|

Refractoriness

(℃)

|

CT℃×3h PLC ≤1%

|

110℃After Drying (MPa)

|

|

||||||

|

|

|

|

|

|

|

CCS

|

MOR

|

||||||

|

Clay Bonded

|

NL-45

|

45

|

―

|

1700

|

1350

|

8

|

1

|

||||||

|

|

NL-60

|

60

|

―

|

1720

|

1400

|

9

|

1.5

|

||||||

|

|

NL-70

|

70

|

―

|

1760

|

1450

|

10

|

2

|

||||||

|

Cement Bonded

|

GL-42

|

42

|

―

|

1640

|

1350

|

25

|

3.5

|

||||||

|

|

GL-50

|

50

|

―

|

1660

|

1400

|

30

|

4

|

||||||

|

|

GL-60

|

60

|

―

|

1700

|

1400

|

30

|

4

|

||||||

|

|

GL-70

|

70

|

―

|

1720

|

1450

|

35

|

5

|

||||||

|

|

GL-85

|

85

|

―

|

1780

|

1500

|

35

|

5

|

||||||

|

Low Cement Bonded

|

DL-60

|

60

|

2.5

|

1740

|

1500

|

30

|

5

|

||||||

|

|

DL-80

|

80

|

2.5

|

1780

|

1500

|

40

|

6

|

||||||

|

Phosphate Bonded

|

LL-45

|

45

|

―

|

1700

|

1350

|

20

|

3.5

|

||||||

|

|

LL-60

|

60

|

―

|

1740

|

1450

|

25

|

4

|

||||||

|

|

LL-75

|

75

|

―

|

1780

|

1500

|

30

|

5

|

||||||

|

Sodium Silicate Bonded

|

BL-40

|

40

|

―

|

―

|

1000

|

20

|

―

|

||||||

|

Product Name

|

|

|

Lightweight Castable

|

|

|

|

|

||||||

|

Working Limit Temperature

|

|

|

1100

|

1200

|

1400

|

1500

|

1600

|

||||||

|

110℃ Bulk Density(g/cm3) ≥

|

|

|

1.15

|

1.25

|

1.35

|

1.40

|

1.50

|

||||||

|

Modulus of Rupture

(MPa) ≥

|

110℃×24h

|

|

2.5

|

3

|

3.3

|

3.5

|

3.0

|

||||||

|

|

1100℃×3h

|

|

2

|

2

|

2.5

|

3.5

|

3.0

|

||||||

|

|

1400℃×3h

|

|

―

|

―

|

3

|

10.8

|

8.1

|

||||||

|

Cold Crushing Strength

(MPa) ≥

|

110℃×24h

|

|

8

|

8

|

11

|

12

|

10

|

||||||

|

|

1100℃×3h

|

|

4

|

4

|

5

|

11

|

10

|

||||||

|

|

1400℃×3h

|

|

―

|

―

|

15

|

22

|

14

|

||||||

|

Permanent Linear Change(%)

|

|

1100℃×3h

|

-0.65 1000℃×3h

|

-0.8

|

-0.25

|

-0.15

|

-0.1

|

||||||

|

|

|

1400℃×3h

|

―

|

―

|

-0.8

|

-0.55

|

-0.45

|

||||||

|

Thermal Conductivity

(W/m.k)

|

|

350℃

|

0.18

|

0.20

|

0.30

|

0.48

|

0.52

|

||||||

|

|

|

700℃

|

0.25

|

0.25

|

0.45

|

0.61

|

0.64

|

||||||

|

Al2O3(%) ≥

|

|

|

33

|

35

|

45

|

55

|

65

|

||||||

|

Fe2O3(%) ≤

|

|

|

3.5

|

3.0

|

2.5

|

2.0

|

2.0

|

||||||

Applications

Iron and Steel Industry

Mainly used for maintenance and patching of electric arc furnaces, steelmaking furnaces, ladles and other equipment.

Non-ferrous Metal Industry

Used for patching and repairing of copper, aluminum, zinc, nickel and other non-ferrous metal smelting furnaces and converters.

Glass Industry

Used for maintenance and patch work of glass furnaces, annealing furnaces and other equipment.

Building Materials Industry

Used for maintenance and patching of building materials production equipment such as cement rotary kiln and gypsum kiln.

Chemical Industry

Used for maintenance and patching of high-temperature chemical equipment such as catalytic cracking furnaces and gasifiers.

Ceramic Industry

Used for maintenance and repair of ceramic production equipment such as tunnel kiln and shuttle kiln.

Package&Warehouse

Hot Searches