- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tongda

-

Voltage:

-

220V/380V

-

Power:

-

Actual Power

-

Dimension(L*W*H):

-

Actual Size

-

Weight (KG):

-

3500

-

Name:

-

electroplating machine equipment

-

After-sales Service Provided:

-

Free spare parts, Overseas service center available

-

Packaging Details:

-

Non-Standard / Wood CTN

-

Surrounding equipments:

-

Rectifier, Filter ,Chiller,Heating pipe

-

Application:

-

Gold,Zinc,Nickel,Copper,Chrome Plating

-

Available for:

-

Zinc Plating /Copper /Nickel,etc...

-

Model:

-

electroplating production line

-

Plating Process:

-

Chrome ,Zinc ,Nickle ,Plating etc.

-

Material:

-

PP /PVC/SS

-

Auxiliary Equipment:

-

Chiller,Rectifier,Heating System

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

anodizing aluminum equipment

-

Marketing Type:

-

New Product 2021

-

Brand Name:

-

Tongda

-

Voltage:

-

220V/380V

-

Power:

-

Actual Power

-

Dimension(L*W*H):

-

Actual Size

-

Weight (KG):

-

3500

-

Name:

-

electroplating machine equipment

-

After-sales Service Provided:

-

Free spare parts, Overseas service center available

-

Packaging Details:

-

Non-Standard / Wood CTN

-

Surrounding equipments:

-

Rectifier, Filter ,Chiller,Heating pipe

-

Application:

-

Gold,Zinc,Nickel,Copper,Chrome Plating

-

Available for:

-

Zinc Plating /Copper /Nickel,etc...

-

Model:

-

electroplating production line

-

Plating Process:

-

Chrome ,Zinc ,Nickle ,Plating etc.

-

Material:

-

PP /PVC/SS

-

Auxiliary Equipment:

-

Chiller,Rectifier,Heating System

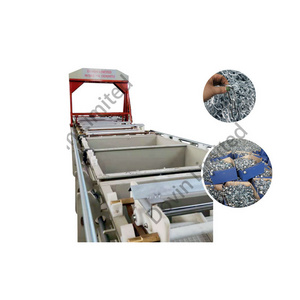

Junan Tongda electroplating equipment barrel rack zinc copper nickel chrome anodizing aluminum plating machine

Electroplating Equipment Parameters

Full-Automatic Machine:

Semi-Automatic Machine:

Single Station:

- Full-auto Machine:

1.High Productivity ,stable quality ,saving time ,human and area

2.Intelligent operating System:Controlled by PLC .Using the Man-Machine touched interface controlling panel,can monitor and adjust

the every process and data.

Using the Man-Machine touched interface controlling panel,can monitor and adjust the every process and data.

- Semi-auto Machine:

1.Using the remote controller . Easy to operate

2.Less investment and with little mechanical problem

3.The motor with reducer transmission to insure the barrel rolling .

Easy to operate.Less investment and with little mechanical problem.

- Single Station:

1.Advantage :Lowest cost, Easy to Operate.Manual lifted up and down

2.Disadvantage: More human charge

Lowest cost.Easy to operate.Manual lifted up ans down.More human charge.

1.High Productivity ,stable quality ,saving time ,human and area

2.Intelligent operating System:Controlled by PLC .Using the Man-Machine touched interface controlling panel,can monitor and adjust

the every process and data.

Using the Man-Machine touched interface controlling panel,can monitor and adjust the every process and data.

- Semi-auto Machine:

1.Using the remote controller . Easy to operate

2.Less investment and with little mechanical problem

3.The motor with reducer transmission to insure the barrel rolling .

Easy to operate.Less investment and with little mechanical problem.

- Single Station:

1.Advantage :Lowest cost, Easy to Operate.Manual lifted up and down

2.Disadvantage: More human charge

Lowest cost.Easy to operate.Manual lifted up ans down.More human charge.

|

Electroplating Machine

|

|

|

|

|||

|

Item Type:

|

Automatic Machine

|

Semi-Automatic Machine

|

Manually Machine

|

|||

|

Coating Type:

|

Zinc, Nickel, Sliver, Gold, Chrome, ABS Plating, Copper, Tin and etc.

|

|

|

|||

|

Type:

|

Hang plating / Barrel plating.

|

|

|

|||

|

Accessories:

|

PP Tank, PP Barrel ,Crane Lifting , Hanger , Rectifier , Chemical Solution etc.

|

|

|

|||

|

After-Sales Service:

|

Provide.

|

|

|

|||

|

Voltage:

|

380V (Welcome Customized).

|

|

|

|||

|

Model Number:

|

Depends on your actual plating products.

|

|

|

|||

|

Lead Time:

|

30 - 35 working days after prepaid.

|

|

|

|||

Pictures of Electroplating Machine

Barrel Plating

Barrel plating production line has reasonable structure, beautiful appearance, safe operation, low noise and easy maintenance.

It is suitable for mass production of various small parts and various plating needs.

High production efficiency, uniform plating and good quality.

It is suitable for mass production of various small parts and various plating needs.

High production efficiency, uniform plating and good quality.

Hang Plating

Hanging plating is a process in which the work piece is clamped on the hanger, suitable for large parts, and the number of

products that can be plated in each batch is small, and the plating thickness is 10 μm or more.

products that can be plated in each batch is small, and the plating thickness is 10 μm or more.

Product Description

Testing before delivery:

(1) Anti-leakage testing :

We will fill the tanks with water after welding and before installation , the testing time last 72 hours.

(1) Anti-leakage testing :

We will fill the tanks with water after welding and before installation , the testing time last 72 hours.

(2) Running testing :

We will installed the equipment and operate it. Meantime, we will take the testing videos to the customer to confirm it .

We will installed the equipment and operate it. Meantime, we will take the testing videos to the customer to confirm it .

Our Factory

We are professional electroplating equipment manufacturer ,

zinc , nickel , chrome , copper, gold and etc.

Our company is a comprehensive high-tech enterprise integrating environmental technology research, production, sales and maintenance.

Electroplating tank, electrolyzer, acid and alkali tank, pickling tank, plastic anti-corrosion plating tank, PP plating tank, PVC plating tank, polypropylene plating tank; electroplating tank is the basic supporting in electroplating equipment.

Specifications can be customized as customers' requirements !

Client Feedback

Sample Pictures

Packing & Delivery

1.Seaworthy packing or according to customers' requirements

2.Delivery Time :30-35 working days after confirming the order.

Hot Searches