- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

SR-0420

-

Warranty:

-

1 year

-

Wire available:

-

0.3-4.0mm2, support customizing

-

Stripping length:

-

0-18mm, support customizing

-

crimping length:

-

Max 12mm

-

Air source:

-

0.5-0.7MPa

-

Voltage:

-

110V/220V

-

Size:

-

430*500*430mm

-

Weight:

-

68kg

-

Function:

-

Stripping, twisting, crimping, auto feeding terminal

-

Control mode:

-

Touch screen and PLC

Quick Details

-

Usage:

-

Stripping and Crimping

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Sinrad

-

Model Number:

-

SR-0420

-

Warranty:

-

1 year

-

Wire available:

-

0.3-4.0mm2, support customizing

-

Stripping length:

-

0-18mm, support customizing

-

crimping length:

-

Max 12mm

-

Air source:

-

0.5-0.7MPa

-

Voltage:

-

110V/220V

-

Size:

-

430*500*430mm

-

Weight:

-

68kg

-

Function:

-

Stripping, twisting, crimping, auto feeding terminal

-

Control mode:

-

Touch screen and PLC

Product Description

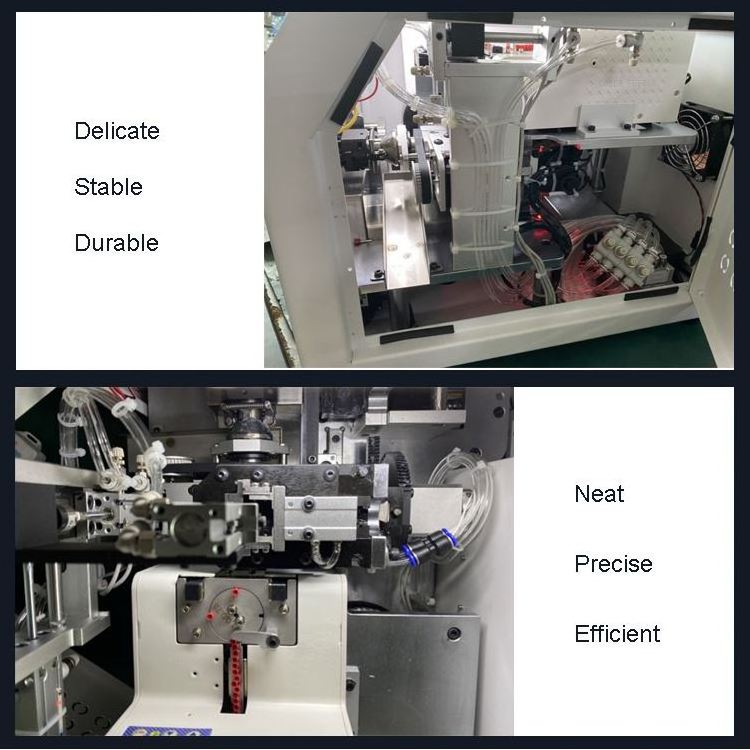

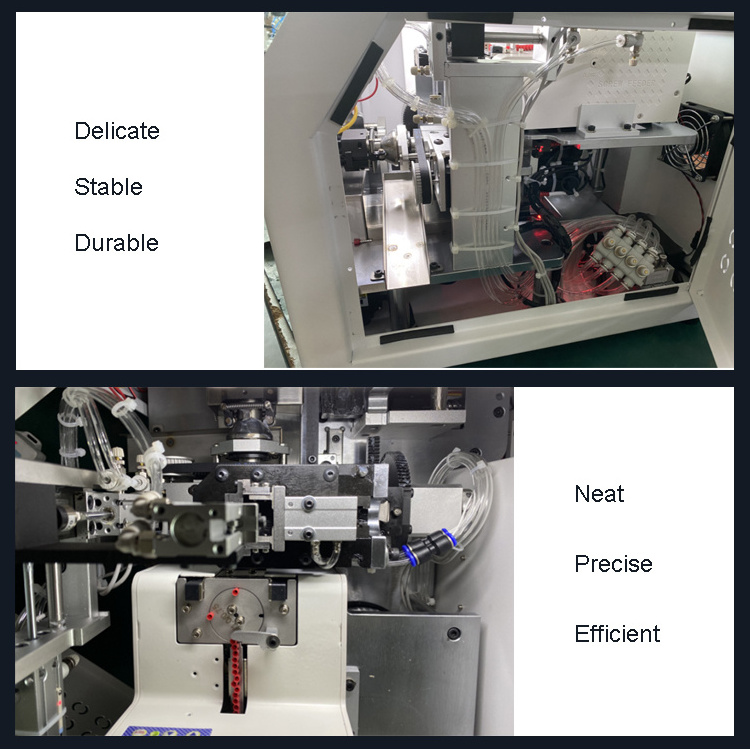

Semi Automatic Insulation Terminal Crimping Wire Stripping machine With Vibrating Bowl

With rotary twisting function, the copper wire insertion process is good, the crimping effect is high quality.

Specification

|

Item

|

Parameter

|

|

Model

|

SR-0420

|

|

Suitable wire

|

0.3-4mm²

|

|

Stripping length

|

0-18mm

|

|

Crimping length

|

Maximum 12mm

|

|

Air source

|

0.5-0.7MPa

|

|

Voltage

|

AC220V/110V 50/60HZ

|

|

Size

|

430*500*430mm

|

|

Weight

|

68KG

|

|

Function

|

Wire inserting, stripping, twisting and crimping can be finished at one time

|

|

Control mode

|

Touch screen and PLC

|

|

Drive mode

|

Motor and ball screw

|

Features:

1. Simplify complex procedures, improve overall efficiency significantly, and have a large cost advantage.

2. The terminals within the specified range do not need to replace the vibration plate, and instantly change the different terminal specifications.

3. Inserting, stripping, twisting and crimping are completed at the same time, mainly for crimping tubular terminals of international standards.

4. The projected part of the wire adopts the shape of the bell mouth to facilitate the inserting.

5. Automatic stripping wire diameter and crimp height adjustment.

6. Adopt sensitive pneumatic induction control, fast crimping.

7. It adopts the feeding method of vibrating plate, which makes the terminal replacement convenient and quick.

8. Imported components and cylinders are used for stable performance.

Our machines:

Wire feeder.

Stripping machine.

Cutting stripping machine.

Crimping machine.

Ultrasonic wire splicing machine.

Soldering machine.

Cutting stripping twisting tinning machine.

Cutting stripping crimping machine.

Cutting stripping crimping tinning machine.

Cutting stripping crimping housing insertion and tinning machine.

Cutting stripping wire seal insertion and crimping machine.

Universal cable tester.

Wire terminal tension tester.

Wire harness sequence tester.

Power cable tester.

Terminal cross section analyzer.

......

Relative Products

Packing & Delivery

PACKAGE:

Standard export carton or plywood case packing.

DELIVERY TIME:

Small machines in stock: 3-7 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Large machines and customized machines: 10-30 days after confirming order and payment.

Standard export carton or plywood case packing.

DELIVERY TIME:

Small machines in stock: 3-7 days after confirming order,detail delivery date should be decided according to production season and order quantity.

Large machines and customized machines: 10-30 days after confirming order and payment.

Hot Searches