- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

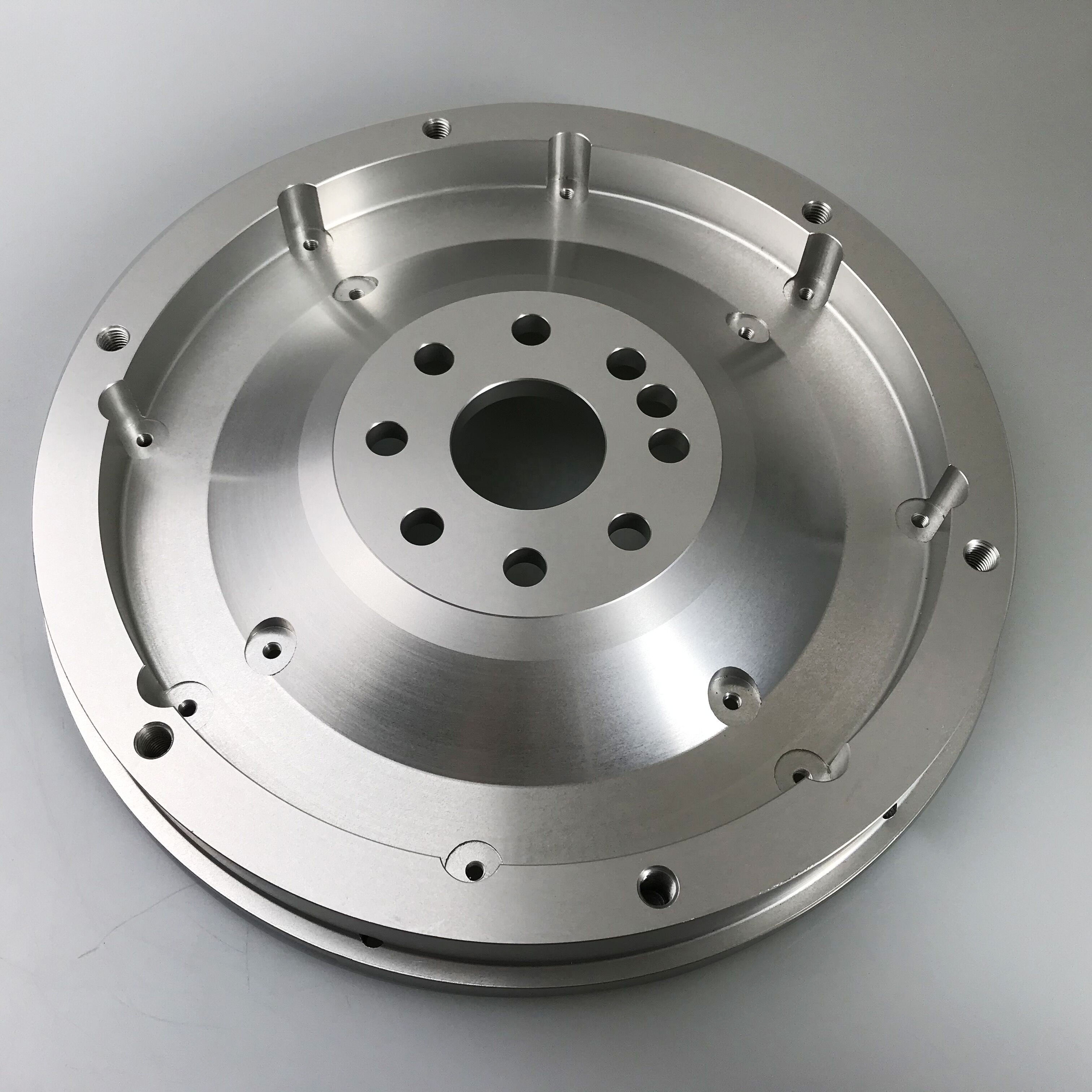

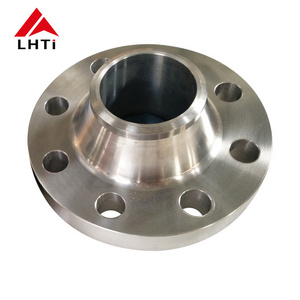

Flange

-

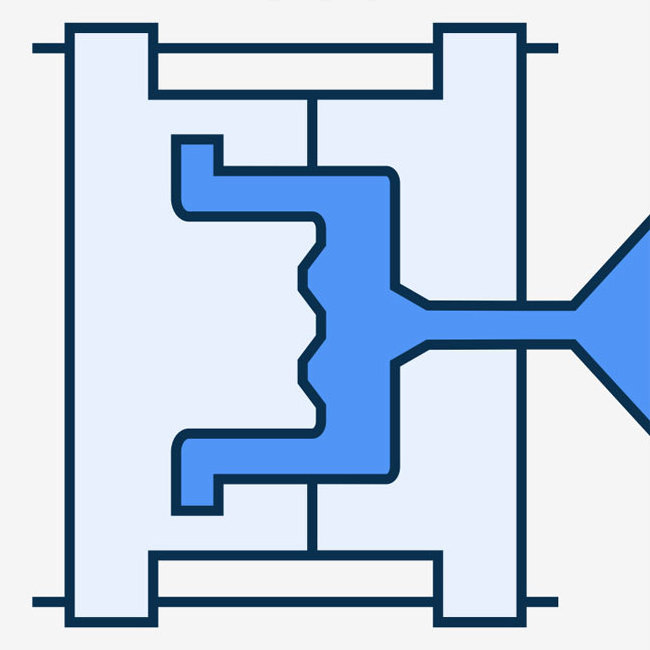

Product name:

-

stainless steel flange

-

Application:

-

Industry,Steam and Gas Turbine,Construction

-

Connection:

-

Welding, butt welded

-

Packing:

-

custom

-

Material:

-

Stainless Steel

-

MOQ:

-

1

-

Technics:

-

Forged

Quick Details

-

Standard:

-

ANSI, bs, DIN, GB, ISO, JIS, Jpi, ASME

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

baijinxin

-

Model Number:

-

Flange

-

Product name:

-

stainless steel flange

-

Application:

-

Industry,Steam and Gas Turbine,Construction

-

Connection:

-

Welding, butt welded

-

Packing:

-

custom

-

Material:

-

Stainless Steel

-

MOQ:

-

1

-

Technics:

-

Forged

Are looking for the right supplier?

CNC Machining Service

-----Low- to High-Volume Sheet Metal Parts in as Fast as 1 Day

On-demand solutions

Capabilities for all of your custom manufacturing applications from prototype to production

CNC machining

We combine the latest precision CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts

Sheet Metal Fabrication

Offers punching, laser cutting, stamping, bending, and welding sheet metal services, Fabrication services range from low-volume

prototyping to high-volume production runs

prototyping to high-volume production runs

Injection Molding

Injection molding aim at cost-effective and quality conform, able to provide you the best solution for tooling development. cost reduction and quality satisfaction are both priorities

Product Description?

|

Product Name

|

stainless steel flange

|

|

|

|

||||

|

Tolerance

|

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

|

|

|

|

||||

|

MOQ

|

Low MOQ Start 1 Pcs ( No need mold cost ) , Many Customer found us make prototype product to save Investment Funds for Pre-R&D and Market Testing

|

|

|

|

||||

|

Sample Cost

|

Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order

.

|

|

|

|

||||

|

Drawing Accepted

|

Solidworks,Pro/Engineer, AutoCAD(DXF,DWG), PDF etc.

|

|

|

|

||||

|

Delivery Time

|

1-25 days after order with prepayment based on products structure and quantity

|

|

|

|

||||

|

|

|

|

|

|||||

product processing capacity?

|

1.Main Materials

|

|

|

|

|

||||

|

Aluminum

|

Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc.

|

|

|

|

||||

|

Stainless Steel

|

SS201,SS301,SS303, SS304, SS316, SS416, etc.

|

|

|

|

||||

|

Steel

|

Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc

.

|

|

|

|

||||

|

Brass

|

C35600, C36000, C37700, C37000, C37100, C28000, C26000, C24000, C22000, etc.

|

|

|

|

||||

|

Copper

|

C11000, C12000, C12200, C10100, etc.

|

|

|

|

||||

|

Iron

|

20#, 45#, Q235, Q345, Q3458, 1214, 12L14, 1215, etc.

|

|

|

|

||||

|

Plastic

|

POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc

|

|

|

|

||||

|

2. Surface Treatment

|

|

|

|

|

||||

|

Stainless Steel

|

Brushed and Polishing, Passivating, Sandblasting, Laser engraving, Gold Plating Etc.

|

|

|

|

||||

|

Steel

|

Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated

|

|

|

|

||||

|

Aluminum Parts

|

Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film, Brushing, Polishing, Powder Coated, Nickel Plated Etc.

|

|

|

|

||||

|

Plastic

|

Plating gold (ABS), Painting, Brushing (Acrylic), laser engraving

|

|

|

|

||||

Technical Support

Shenzhen Baijinxin Group is a professional at independent development and design. Our engineers are skilled at AUTO CAD, PRO ENGINEER, SOLID, SketchUp. 3D max WORKS and other 2D & 3D software. We are able to design, develop, produce and deliver your PO according to your drawings, samples, or just an idea. control of non-standard products and OEM products.

Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have a full inspection and routing inspection during mass production---In-process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Here are the inspection reports before every shipment.

Buyers Reviews?

Hot Searches