- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Kafan

-

Voltage:

-

380V/customized

-

Power:

-

12 KW

-

Dimension(L*W*H):

-

It depends

-

Weight (KG):

-

3000

-

Equipment Name:

-

Horizontal Pull Manual Powder Coating Line

-

Inner Size:

-

L5.5m x W2.8m x H3.1m

-

Opening Size:

-

W2.8m x H2.9m

-

Material:

-

SPCC/t=1.5mm, with door

-

Bottom Frame:

-

8# square tube

-

Booth Inner Frame:

-

8# square tube

-

Recovery System:

-

Filter Cartridge (12pcs)

-

Fan Motor:

-

3kw, 4sets

-

Air Flow:

-

4050m^3/h

Quick Details

-

Machine Type:

-

Powder Coating Plant, Spray Booths, Painting Equipment, Drying Oven

-

Marketing Type:

-

Powder Coating Plant

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Kafan

-

Voltage:

-

380V/customized

-

Power:

-

12 KW

-

Dimension(L*W*H):

-

It depends

-

Weight (KG):

-

3000

-

Equipment Name:

-

Horizontal Pull Manual Powder Coating Line

-

Inner Size:

-

L5.5m x W2.8m x H3.1m

-

Opening Size:

-

W2.8m x H2.9m

-

Material:

-

SPCC/t=1.5mm, with door

-

Bottom Frame:

-

8# square tube

-

Booth Inner Frame:

-

8# square tube

-

Recovery System:

-

Filter Cartridge (12pcs)

-

Fan Motor:

-

3kw, 4sets

-

Air Flow:

-

4050m^3/h

Product Description

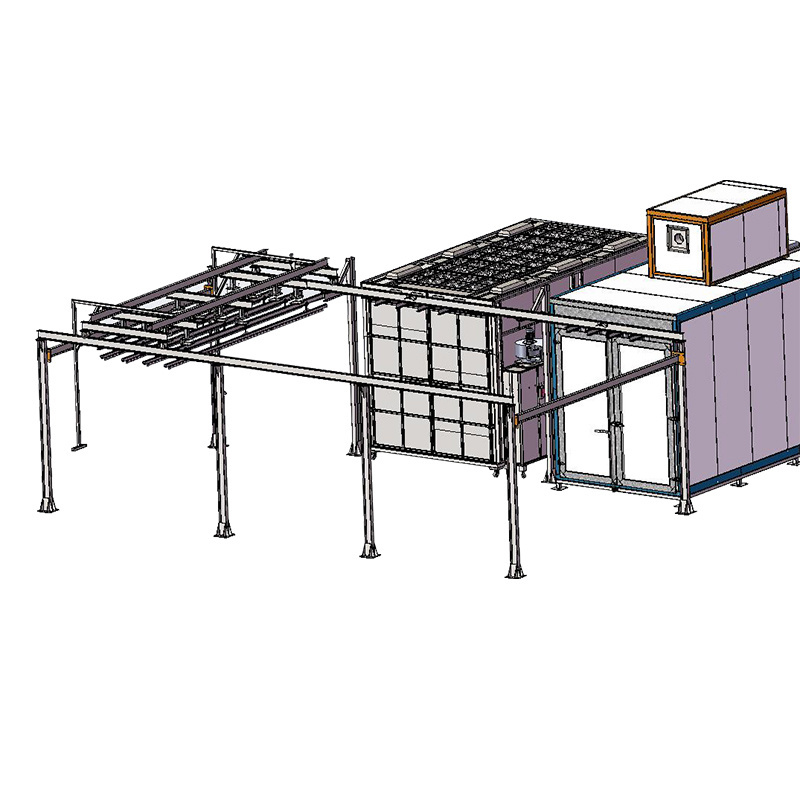

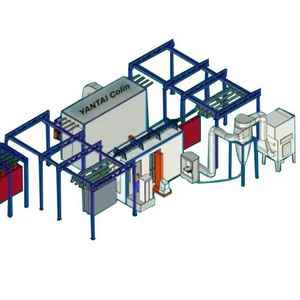

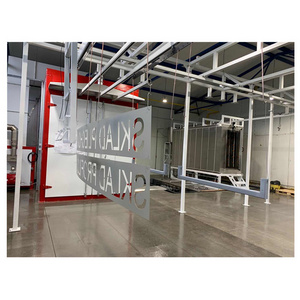

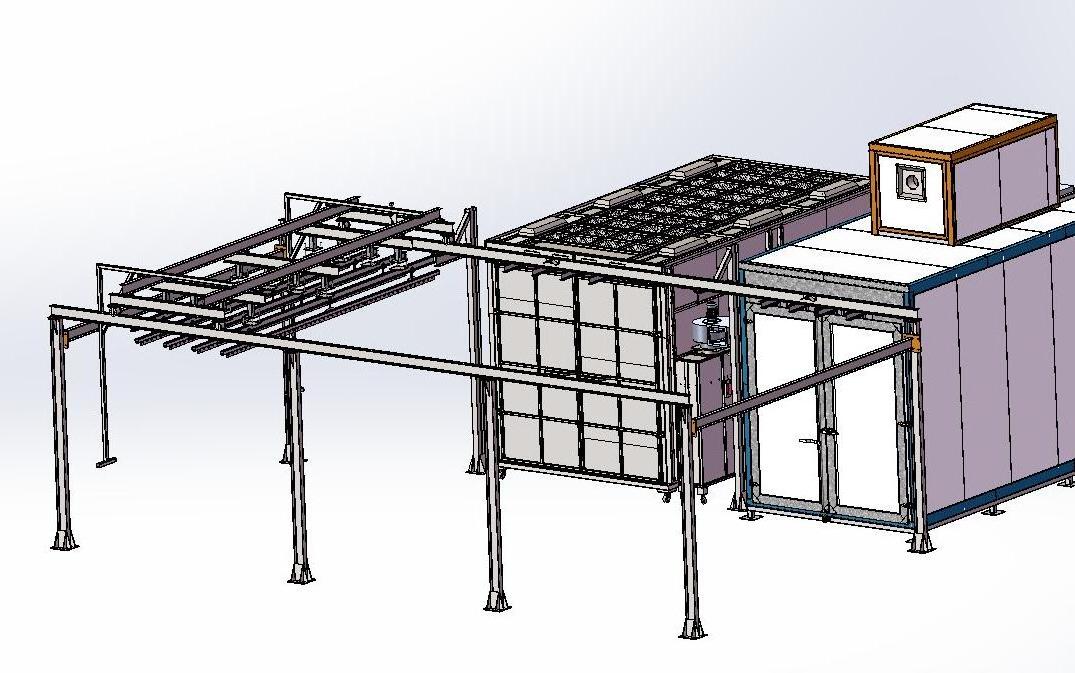

Horizontal Pull Manual Powder Coating Line

This manual powder coating line is specially designed for our Australia customer for their batch production needs based on manual operation. It includes powder coating room with filter recovery, gas curing oven, manual coating equipment and overhead track system.

The powder coating line can achieve big production of small workparts, also Ideal to handle large parts or complex-shape parts with more precise jobs than in automatic line.

Details Images

COLO-191S Manual Powder Coating Gun

1. Flexibly, precisely control all the electrostatic and pneumatic parameters to optimize processing.

2. Create excellent uniform finish even with challenging powders and complex workparts.

3. Three pre-set application programs are designed for beginners, application for flat parts, profiles and re-coating.

4. Allows advanced users customize 20 programs optimized for their parts and powder, and easily recall them for use the next time.

5. 100kv manual spray guns delivers long-lasting high transfer efficiency

6. 60lbs fluidizing powder hopper is welled sealed to avoids damp and contaminated.

|

Model

|

COLO-191S

|

|

Power range

|

220V/110V

|

|

Frequency

|

50HZ/60HZ

|

|

Temperature range in use

|

-10 ℃+50 ℃

|

|

Powder Gun Data

|

Gun weight: 500G

Rated output voltage 24VDC Maximum output current 180Ua(max) Maximum output voltage 0-100KV ( adjustable) Maximum powder injection : 600g/min Polarity negative (-) |

|

Pheumatic Data

|

Maximum input-air pressure 10kg/cm

Optimum input-air pressure 6kg/cm Minimum input-air pressure 4kg/cm Maximum water vapor content or compressedair 1.4g/N m3 Maximum oil vapor content of compressed air 0.1ppm Maximum compressed-air consumption 13.2 m3/h |

COLO Walk in Powder Coating Booth

1. Powder spraying with two side doors closed provides a safe and clean workshop.

2. Powder reclaim is achieved by a recovery stage, which is combined with 12pcs pieces of high precision filters, reach high powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valve for extended filter life.

4. PLC provides all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

2. Powder reclaim is achieved by a recovery stage, which is combined with 12pcs pieces of high precision filters, reach high powder recycling rate.

3. Filter cleaning is automatically done through pulse solenoid valve for extended filter life.

4. PLC provides all the functions you need, control the fan working, set interval and time of pulse jet for filter cleaning.

|

Inner Size

|

L5.5m x W2.8m x H3.1m

|

|

Opening Size

|

W2.8m x H2.9m

|

|

Material

|

SPCC/t=1.5mm, with door

|

|

Bottom Frame

|

8# square tube

|

|

Booth Inner Frame

|

8# square tube

|

|

Recovery System

|

Filter Cartridge (12pcs)

|

|

Fan Motor

|

3kw, 4sets

|

|

Air Flow

|

4050m^3/h

|

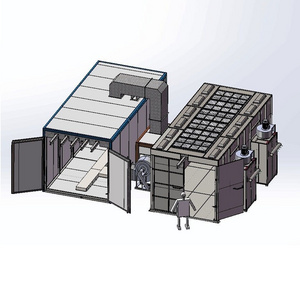

COLO Powder Coating Oven

1. Gas heating oven is more clean and cost-saving, quick raising of high temperature increase production efficiency.

2. A powerful circulation fan makes even temperature in inner chamber ensure high quality curing results.

3. 100mm thickness rock wool board of the interlayer, keep long time heat preservation.

4. PLC panel control the working of fan, setting the heating time and temperature.

2. A powerful circulation fan makes even temperature in inner chamber ensure high quality curing results.

3. 100mm thickness rock wool board of the interlayer, keep long time heat preservation.

4. PLC panel control the working of fan, setting the heating time and temperature.

|

Working Dimension

|

Width 2.5m x Height 3.1m x Depth 5.6m

|

|

Insulation

|

t=100mm

|

|

Hemming

|

SGCC/t=1.5mm

|

|

Bottom Frame

|

8# Square Tube

|

|

Inner Frame

|

8# Square Tube

|

|

Gas Burner

|

300,000 cal/h, RIELLO brand

|

|

Fan Motor

|

11kw, 1 set

|

|

Air Flow

|

12000-14000m^3/h

|

Application

Recommend Products

Customer Feedback

Product packaging

Hot Searches