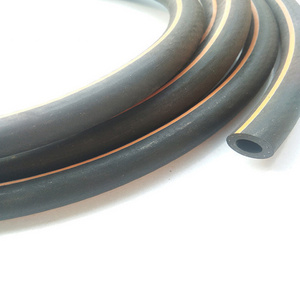

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

PR6 SERIES

-

Working pressure:

-

20bar

-

Burst Pressure:

-

60bar

-

Reinforcement:

-

High strength texitel

-

Working Temperature:

-

-35 ℃ to +100 ℃

-

Tube:

-

Smooth Black Fuel Resistant nitrile synthetic rubber

-

Cover:

-

Smooth Black Ozone and Abrasion Resistant nitrile synthetic rubber

-

Color:

-

Black

-

OEM:

-

Acceptable

-

Service:

-

Customize Priting, packaging

Quick Details

-

Processing Service:

-

Cutting, Printting

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Passion

-

Model Number:

-

PR6 SERIES

-

Working pressure:

-

20bar

-

Burst Pressure:

-

60bar

-

Reinforcement:

-

High strength texitel

-

Working Temperature:

-

-35 ℃ to +100 ℃

-

Tube:

-

Smooth Black Fuel Resistant nitrile synthetic rubber

-

Cover:

-

Smooth Black Ozone and Abrasion Resistant nitrile synthetic rubber

-

Color:

-

Black

-

OEM:

-

Acceptable

-

Service:

-

Customize Priting, packaging

Hose Description

Tube

: NBR

Reinforcement : High tensile polyester fiber braided.

Cover : Rubber-Plastic blend rubber

Temperature : -35ºC to +100ºC

Standard Color : Black

Application : For use with gasoline, diesel fuel, lubrication oil, or the vapor present in either the fuel system or in the

crankcase of internal combustion engines in mobile, stationary, and marine applications.

Standard : SAE J30 R6

Standard length : 30m, 100m.

Reinforcement : High tensile polyester fiber braided.

Cover : Rubber-Plastic blend rubber

Temperature : -35ºC to +100ºC

Standard Color : Black

Application : For use with gasoline, diesel fuel, lubrication oil, or the vapor present in either the fuel system or in the

crankcase of internal combustion engines in mobile, stationary, and marine applications.

Standard : SAE J30 R6

Standard length : 30m, 100m.

NOTE: Do not use for pressure lines or fuel injected engines.

Specifications

|

Inner

Diameter

|

|

Outer

Diameter

|

Working Pressure

|

Burst Pressure

|

Length

|

Measurement

|

Weight

|

|

|

inch

|

mm

|

mm

|

psi

|

psi

|

m

|

cbm/roll

|

kg/m

|

|

|

3/16"

|

5

|

11.5

|

300

|

900

|

100

|

0.028

|

0.15

|

|

|

1/4"

|

6

|

13

|

300

|

900

|

100

|

0.031

|

0.17

|

|

|

5/16"

|

8

|

15

|

300

|

900

|

100

|

0.0353

|

0.216

|

|

|

3/8"

|

10

|

17

|

300

|

900

|

100

|

0.0442

|

0.24

|

|

|

1/2"

|

12.7

|

22

|

300

|

900

|

100

|

0.0756

|

0.428

|

|

|

5/8"

|

16

|

25

|

300

|

900

|

50

|

0.0329

|

0.40

|

|

|

3/4"

|

19

|

29

|

300

|

900

|

50

|

0.0572

|

0.60

|

|

|

1"

|

25

|

36

|

300

|

900

|

50

|

0.099

|

0.84

|

|

Certifications

TUV Certificate

RoHS

ISO Certificate

CE Certificate

MSHA Certificate 1

MSHA Certificate 2

Paishun has various types of certificates, such as ISO, CE, Rohs, MSHA, etc.

Exhibitions

More of Paishun

|

Paishun Sales Network

|

|

|

|

|

||||

We have a wide range of global market. Our rubber hoses and hose assemblies are exported to USA, Canada, UK, Norway, Germany, Spain, Portugal, Denmark, Australia, Japan, Thailand, Sri Lanka, Vietnam, Peru, Chile, Argentina, South Africa etc, more than 90 countries all over the world.

|

About Paishun

|

|

|

|

|

||||

Paishun factory covers a land of over 3 hectares, and the workshops occupy a surface of 25000 square meters. We own complete production lines of the rubber mixing process, cold feeding material extrusion process, microwave vulcanization process, and high-speed braiding process, etc.

We produce mainly industrial hoses like Air Hose, Water Hose, Oil Hose, Welding Hose, Hydraulic Hose, and Assemblies. Paishun, being a rapidly growing enterprise focusing on the professional production of pure rubber hoses and braided rubber hoses, its yearly production capacity reaches 10 million meters.

Our key policy is "enterprise may thrive with the technology, and may last with good quality". So we put much investment in the research team, and in advanced testing laboratory equipment. We now use a series of tensile testing machines, vulcanization testing devices, aging testing chest, pressure testing machines to ensure effective quality control. All these testing machines and related procedures may form a complete quality control system, beginning from the selection of the raw materials until the end step. Thus, we wish our products can satisfy all of our customers, and help them to gain more and more market share.

We produce mainly industrial hoses like Air Hose, Water Hose, Oil Hose, Welding Hose, Hydraulic Hose, and Assemblies. Paishun, being a rapidly growing enterprise focusing on the professional production of pure rubber hoses and braided rubber hoses, its yearly production capacity reaches 10 million meters.

Our key policy is "enterprise may thrive with the technology, and may last with good quality". So we put much investment in the research team, and in advanced testing laboratory equipment. We now use a series of tensile testing machines, vulcanization testing devices, aging testing chest, pressure testing machines to ensure effective quality control. All these testing machines and related procedures may form a complete quality control system, beginning from the selection of the raw materials until the end step. Thus, we wish our products can satisfy all of our customers, and help them to gain more and more market share.

|

Why Choose Paishun

|

|

|

|

|

||||

RELATIONSHIPS

Long term business relationships are of upmost importance to us at Paishun. With our roots planted as a manufacturer, we take the time to learn about your business and your individual needs so we can provide better service to you. We pride ourselves on maintaining long term business relationships and understand that it takes time to build trust in new ones.

QUALITY

Paishun is ISO 9001:2015 certified for the manufacturing of rubber hoses. This certification encompassed with lean manufacturing allows us to ensure our products are safe, reliable and of superior quality.

Our workshop upholds strict cleanliness guidelines at all times. We maintain a clean and organized environment. This allows us to guarantee your hoses are produced promptly and efficiently.

Our workshop upholds strict cleanliness guidelines at all times. We maintain a clean and organized environment. This allows us to guarantee your hoses are produced promptly and efficiently.

SHORT LEAD TIMES

We have continually made improvements to our manufacturing process over 12+ years. We've implemented lean manufacturing and moved to a larger workshop. These changes have enabled us to support growth and streamlined our supply chain process in order to respond quickly to market change. All with the goal to decrease lead time and improve quality.

INVENTORY MANAGEMENT

A consistent unbroken supply chain allows us to produce rubber hoses at a steady pace. We understand how important production scheduling and inventory flow are to your business. We will work with you on an individual basis and will process blanket orders to assist with your inventory level. All of our materials are sourced from big group company such as China Petro and Sinopec, to adhere to our best quality standard.

Hot Searches