Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Hansu

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

100m*10*15m

-

Power (kW):

-

160

-

Weight:

-

30T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training

-

Model Number:

-

HS-D95/250

-

Foaming agent:

-

CO2/cyclopentane

-

Raw material:

-

PET Granule

-

Name:

-

new type PET foam board production line

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Russia, South Korea, Ukraine

-

Certification:

-

CE ISO9001

Quick Details

-

Screw Design:

-

Double-screw

-

Screw Speed (rpm):

-

300 rpm

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Hansu

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

100m*10*15m

-

Power (kW):

-

160

-

Weight:

-

30T

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support, Field installation, commissioning and training

-

Model Number:

-

HS-D95/250

-

Foaming agent:

-

CO2/cyclopentane

-

Raw material:

-

PET Granule

-

Name:

-

new type PET foam board production line

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

Russia, South Korea, Ukraine

-

Certification:

-

CE ISO9001

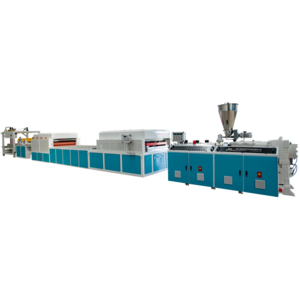

NEW type PET foam board production line

In 2018, after nearly two years of independent research and development by our team,

the first PET foam board production line was tested and put into production

, and successfully started up in 2019, which makes our company take a new step to enter the new field of plastic industry.

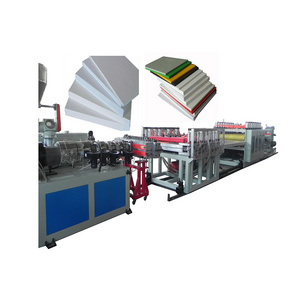

Model disctription:

Main extruder Screw diameter Driving motor (kw) Extrusion capacity (kg/h) Range of product density (kg/m³) Thickness range of product (mm)

D85/200 85/200 132/90 400-600 60-250 or higher 20-80

D95/250 95/250 160/132 500-800 60-250 or higher 30-100

Equipment list

Required equipment:

1.

Pre-crystallization drying system

2.

Loss-in-weight metering feeding system

3.Foam agent injection system (Linde or Lewa for option )

Foaming agent : CO2+Cyclopatene

4.Main extrusion and molding system

5.Downstream equipment

6.

Other auxiliary equipment

Aavanced technology

High cost-performance

Show the running line

It can help you know more about working condition of our line.

|

Item

|

Questions and anwers (For the standard production line)

|

|

|

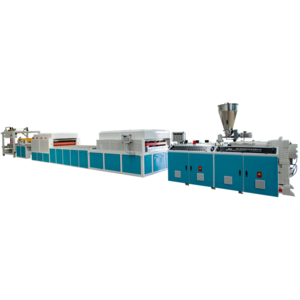

1. The complete set of production covers an area of (L*W*H) : 100-*8*15M,

We can design according to customer’s workshop. 2. Installed power of production line: Around 1000KW (b ased on capacity 400-600kg/h) 3. Operating workers: 2-4 workers |

|

About the installation & commissioning

|

1. Test machines before delivery.

2. After the machines arrive at customer’s workshop, our engineers will come to do installation and commissioning of the equipment. 3. If conditions of customer's site is ready, normally require 30 days for installing and commissioning. |

|

About the after-sale service

|

1.One year guarantee, supply one year wearing parts and spare parts.

2. Provide technical service at any time during your production. 3. After the guarantee period, we will deliver the spare parts by DHL. |