- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

jiangsu

-

Brand Name:

-

Feininger

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

Model

-

Power (kW):

-

50

-

Weight:

-

1500 KG

-

After Warranty Service:

-

Video technical support

-

Name:

-

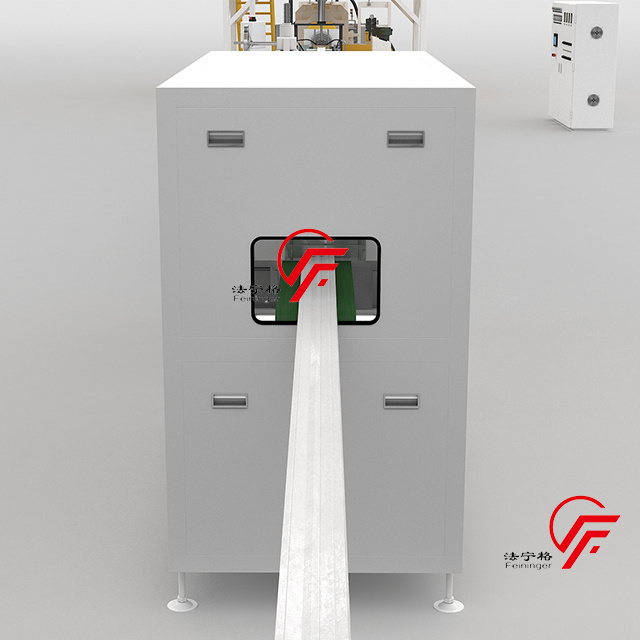

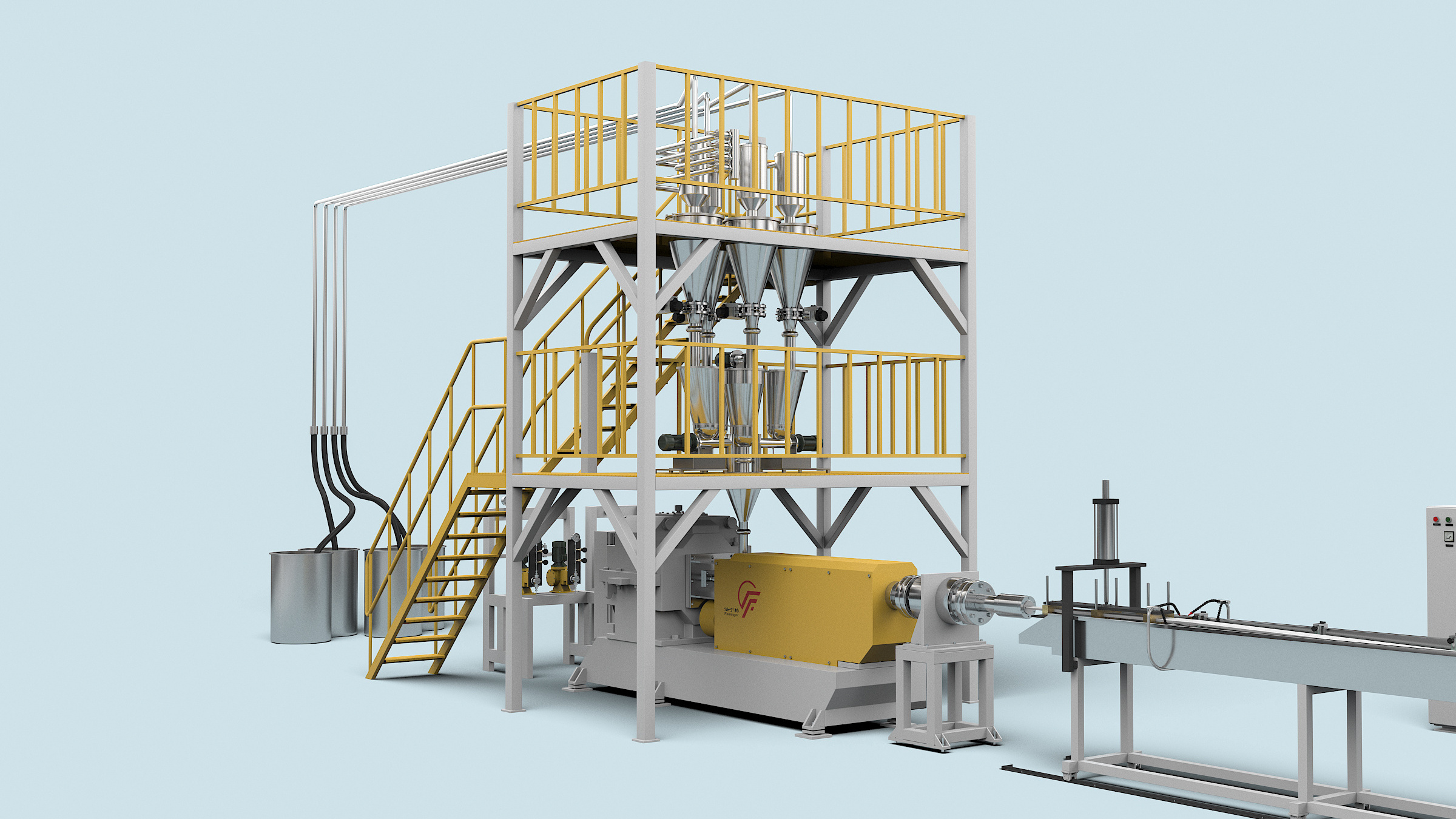

PS Foam Cornice Moulding Extrusion Line

-

Screw type:

-

Double-screw Screw

-

Origin:

-

Nanjing, Jiangsu, China

-

OEM:

-

Acceptable

-

Extruder:

-

Double Screw Extruder Machine

-

Capacity:

-

35-60kg/h

-

Brand:

-

Feininger

-

Port of export:

-

Nanjing/ Shanghai

-

Marketing Type:

-

New Product

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

30:1

-

Screw Speed (rpm):

-

200 rpm

-

Place of Origin:

-

jiangsu

-

Brand Name:

-

Feininger

-

Voltage:

-

380V 50HZ 3phase

-

Dimension(L*W*H):

-

Model

-

Power (kW):

-

50

-

Weight:

-

1500 KG

-

After Warranty Service:

-

Video technical support

-

Name:

-

PS Foam Cornice Moulding Extrusion Line

-

Screw type:

-

Double-screw Screw

-

Origin:

-

Nanjing, Jiangsu, China

-

OEM:

-

Acceptable

-

Extruder:

-

Double Screw Extruder Machine

-

Capacity:

-

35-60kg/h

-

Brand:

-

Feininger

-

Port of export:

-

Nanjing/ Shanghai

-

Marketing Type:

-

New Product

Products Description

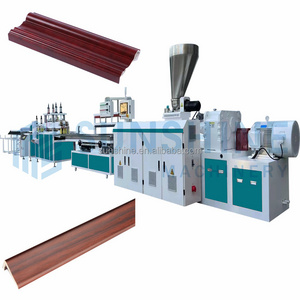

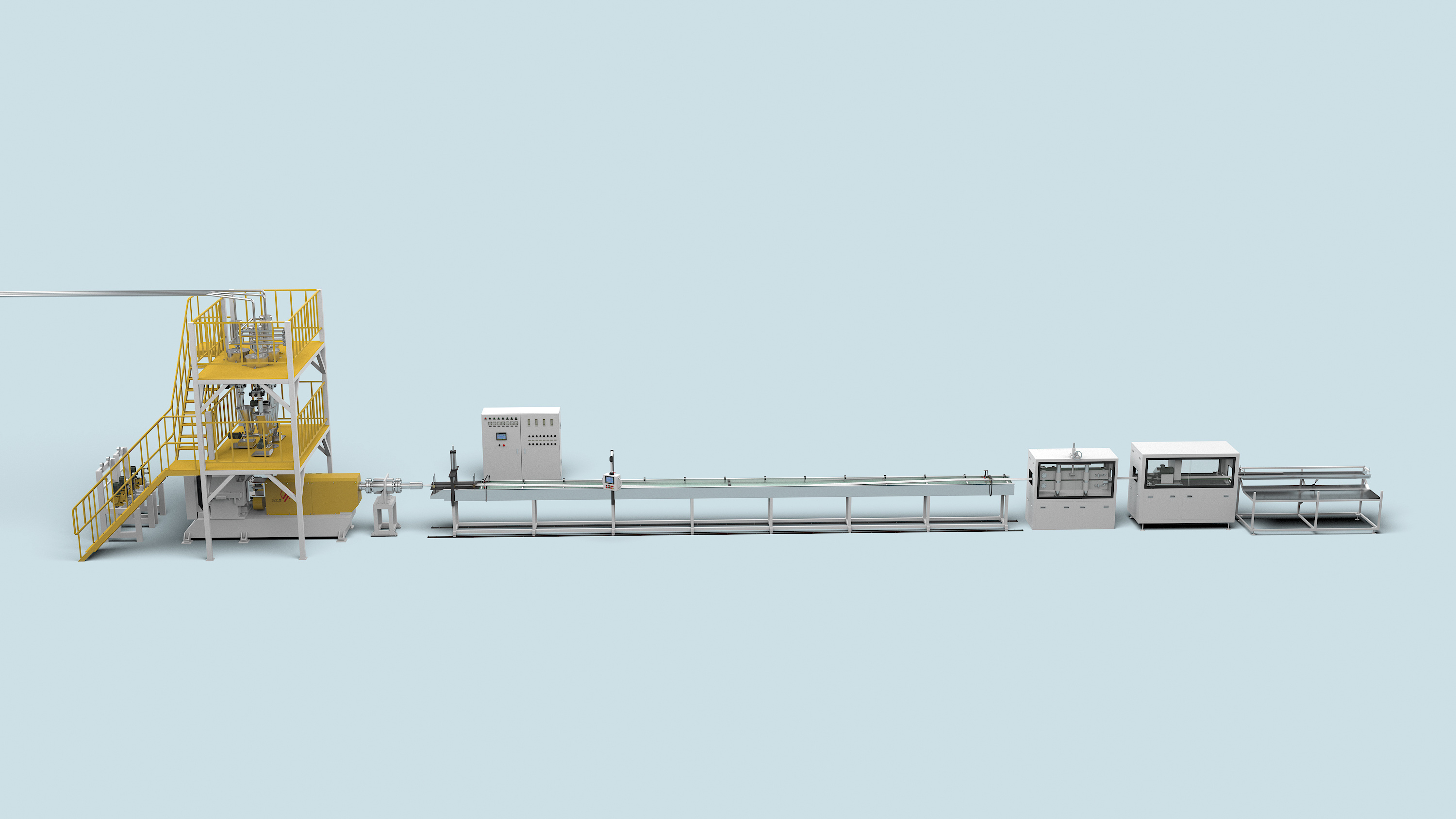

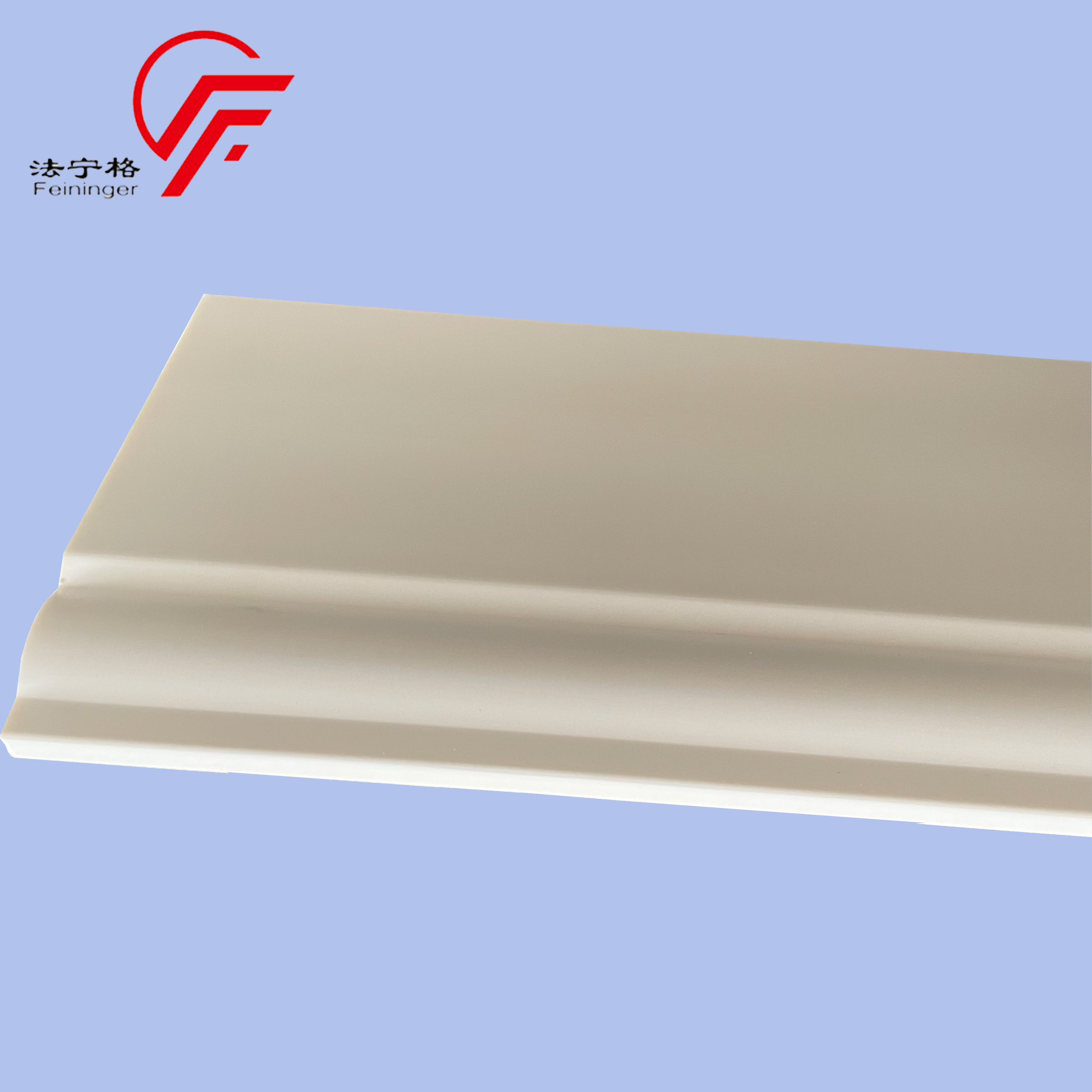

Feininger plastic PS baseboard production line is our company successfully developed a composite self-invented technology, which is different from traditional chemical foaming. Our skirting board extrusion line adopts supercritical CO2 physical foaming, that greatly reduces the product density and makes the product more environmentally friendly. The production line is mainly used to produce profiles from GPPS foam resin. The profiles are widely used to make photo frame, optical frame, door frame board, skirting board and wood-like molding, etc.

|

Model

|

Extruder Type

|

Length/

Diameter |

Foam Output

(kg/hr) |

Blowing Agent

(Gas) |

Thickness of Profile

(mm) |

Width of Profile

(mm) |

|

CS-75T

|

TE75

|

22-26

|

20-80

|

100% CO2

|

5-15

|

25-150

|

|

CS-85T

|

TE85

|

22-24

|

40-150

|

|

8-20

|

40-220

|

|

CS-95T

|

TE95

|

22-24

|

60-250

|

|

8-20

|

65-300

|

Our Products

Successful Case

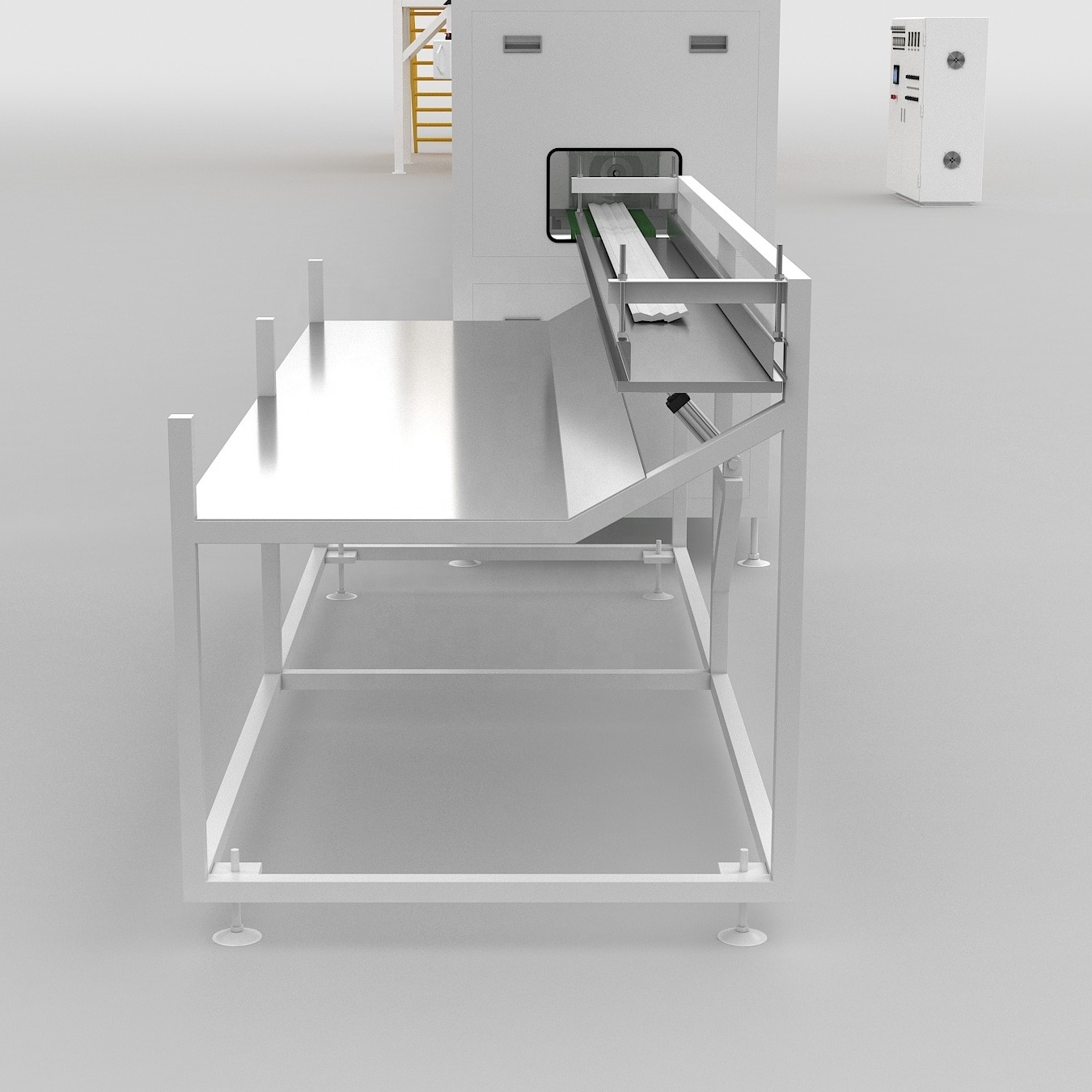

Production Process

1. Add the raw materials to be processed in a certain proportion and pour it into the mixer.

2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.

3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.

4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat is

homogenized.

5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.

6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.

7. Then the material is cooled through a water channel.

8. The products are drawn to a tractor and cut with a fixed length.

9. Finally, it is formed into a qualified product and packaged and sold.

2. After regular mixing and homogenizing, they are transported to a quantitative feeder bin by a feeder.

3. The feeder is evenly fed to the outlet of the main extruder according to the addition amount set by the customer.

4. The raw material is conveyed to the heat exchanger by the high-temperature screw of the main engine, and the heat is

homogenized.

5. Then the material is conveyed to the extrusion equipment after the die, in which carbon dioxide foaming agent is injected quantitatively.

6. The material model of high-temperature products made by mould is formed after cooling into a two-stage shaping jacket.

7. Then the material is cooled through a water channel.

8. The products are drawn to a tractor and cut with a fixed length.

9. Finally, it is formed into a qualified product and packaged and sold.

Certifications

Factory Strength

Exhibition

FAQ

1.

Q: Are you manufacturer ?

A: Yes, manufacturer of XPS Extrusion Line & XPS foam board.

2.

Q:Where are you?

A: Nanjing, capital of Jiangsu Province. It takes 80 minutes from Shanghai to us by fast train.

3.

Q: Can we see the running machine?

A: Yes, we have 3 lines in factory, producing XPS for domestic China and South-eastern Asian countries. When you visit us, you will see the running line.

Hot Searches