Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC Machinery

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1500*1600*2200mm, 1500*1600*2200mm

-

Power (kW):

-

100

-

Weight:

-

5T

-

Name:

-

Wood Profile Extruding Machine

-

Raw material:

-

WPC

-

Usage:

-

Decoration

-

Processing Type:

-

PVC Profile Extrusion

-

Color:

-

Selectable

-

Inverter:

-

ABB

-

Motor:

-

Germany SIEMENS Motor

-

Temperature controller:

-

RKC

-

Certification:

-

CE

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

Unapplicable

-

Screw Speed (rpm):

-

100 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

ACC Machinery

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1500*1600*2200mm, 1500*1600*2200mm

-

Power (kW):

-

100

-

Weight:

-

5T

-

Name:

-

Wood Profile Extruding Machine

-

Raw material:

-

WPC

-

Usage:

-

Decoration

-

Processing Type:

-

PVC Profile Extrusion

-

Color:

-

Selectable

-

Inverter:

-

ABB

-

Motor:

-

Germany SIEMENS Motor

-

Temperature controller:

-

RKC

-

Certification:

-

CE

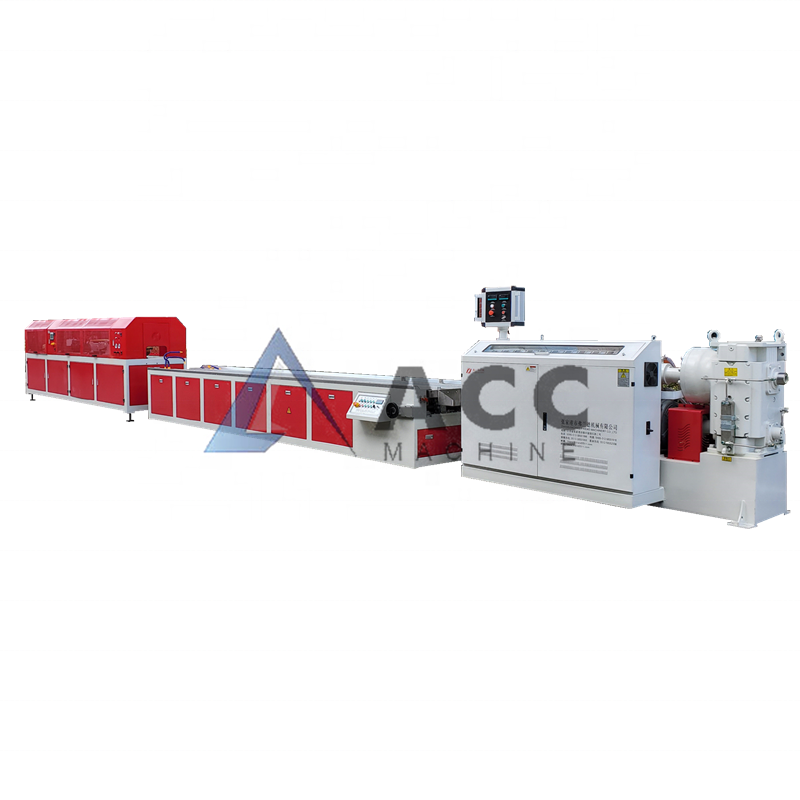

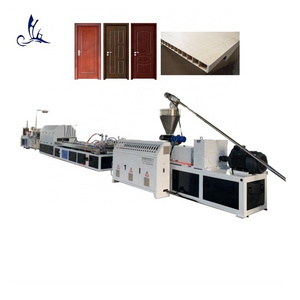

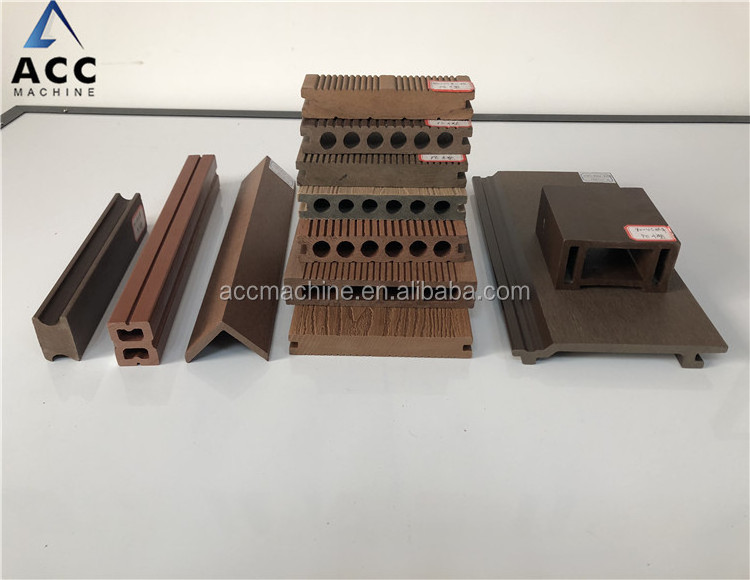

WPC Profile Production Line

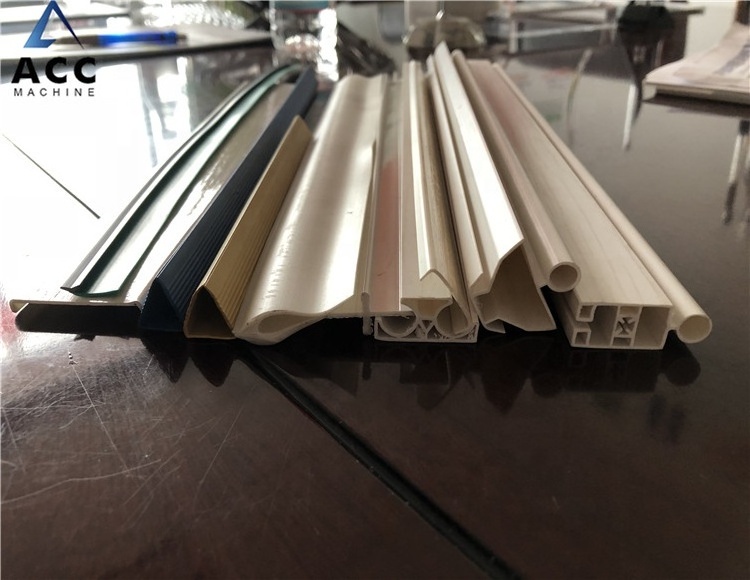

To produce PVC profile, we shall have high speed mixer to mix PVC powder, CACO3 and other additives according to formulas. Then feed the mixture to the conical twin screw extruder for the production. The mixed material will be extruded through different molds to produce different shape profiles. Then it will be calibrated to keep the shape by vacuum calibration tank, then haul off and cutting. You could cut different length as you want, 4 meter, 6 meter, etc.

To produce PVC profile, we shall have high speed mixer to mix PVC powder, CACO3 and other additives according to formulas. Then feed the mixture to the conical twin screw extruder for the production. The mixed material will be extruded through different molds to produce different shape profiles. Then it will be calibrated to keep the shape by vacuum calibration tank, then haul off and cutting. You could cut different length as you want, 4 meter, 6 meter, etc.

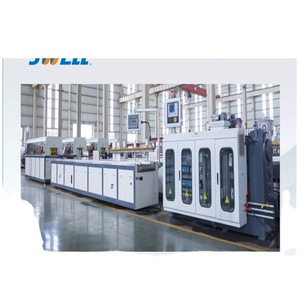

To guarantee the quality and good performance of our machines, we use Siemens Beide brand main motor for extruder, and ABB inverter for speed control. The lower voltage electrics components are from Siemens or Schneider, temperature control device is from Ormon or RKC.

Siemens PLC and Siemens touch screen computer is also available to meet your specific requirements.

The PVC Profile production line includes the below machines;

1. Conical Twin Screw Extruder

2. Extrusion Mold ( The buyer shall prepare the drawing to make the mold)

3. Vacuum Calibration Table

4. Haul Off and Cutter

5. Stacker

6. PVC Mixer ( for raw material preparation)

7. Crusher and Milling Machine ( for recycle the waste and could reuse for profile production)

| Item | SJSZ-45 | SJSZ-51 | SJSZ-55 | SJSZ-65 | SJSZ-80 | SJSZ-92 |

| Diameters of screw(mm) | 45/90 | 51/105 | 55/113 | 65/132 | 80/156 | 90/188 |

| Numbers of screw | 2 | 2 | 2 | 2 | 2 | 2 |

| Direction of screws | Different to the outward | |||||

| Screw rotation speed(rpm) | 1-45 | 1-45 | 40 | 1-35 | 1-37 | 1-33 |

| Effective length of screw(mm) | 985 | 1070 | 7200 | 1440 | 1800 | 2500 |

| Extruder motor power(kw) | 15 | 18.5 | 22/30 | 37 | 55 | 90 |

| Barrel heating power(kw) | 12 | 18 | 18 | 24 | 36 | 86.8 |

| Production capacity(kg/h) | 120 | 80-150 | 150-180 | 250-300 | 320-400 | 600-800 |

| Center height(mm) | 1000 | 1000 | 1000 | 1000 | 10001 | 1200 |

| Net weight (kg) | 2800 | 3200 | 3500 | 4000 | 5000 | 8000 |

| Dimensions(mm) | 3300*1200*2100 | 3600*1100*2100 | 3600*1100*2100 | 4235*1520*2450 | 4750*1550*2460 | 6725*1550*2841 |