- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

15*1.5*1.8

-

Weight:

-

3 KG

-

Machine name:

-

fried instant noodle production line

-

Material of instant noodle:

-

wheat flour

-

Function:

-

Multifunction

-

Capacity:

-

8000-11000pcs

-

shape of instant noodle:

-

round or quadrate

-

Feature:

-

High Efficiency

-

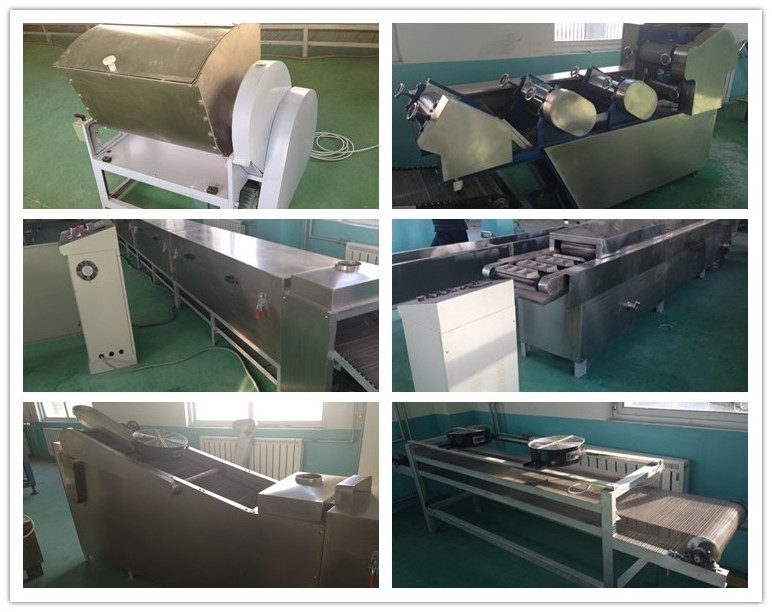

flow chat:

-

mixer, pressor, steam, fryer, cooling converyor, packing machine

-

energy use:

-

electric, steam

Quick Details

-

Production Capacity:

-

8000-11000pcs 8 hours

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Joyang

-

Voltage:

-

380V/50HZ

-

Power:

-

2.2kw

-

Dimension(L*W*H):

-

15*1.5*1.8

-

Weight:

-

3 KG

-

Machine name:

-

fried instant noodle production line

-

Material of instant noodle:

-

wheat flour

-

Function:

-

Multifunction

-

Capacity:

-

8000-11000pcs

-

shape of instant noodle:

-

round or quadrate

-

Feature:

-

High Efficiency

-

flow chat:

-

mixer, pressor, steam, fryer, cooling converyor, packing machine

-

energy use:

-

electric, steam

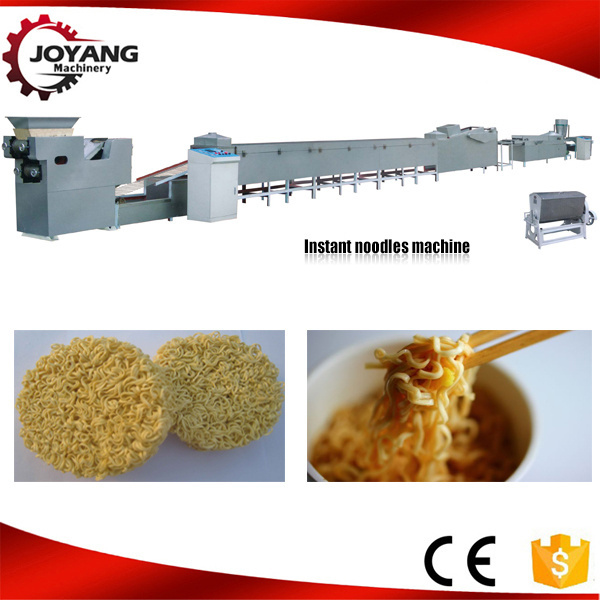

Fried Instant Noodles Making Precessing Machine Production Line

Instant noodles become one of the major modern food consumption, which is characterized by: convenient, diverse tastes to meet the people's demand for food. We specialize in the production of instant noodles machine.

Design and provide different productivity equipment, fried type, to meet the customer's different kinds of requirements. Also, the fried instant noodle production line can be customized according to customer specific requirements.

Technical

Flow chat

Detail

Samples

Packaging and shipping

Packing:

Inside: plastic bag for the fried instant noodle production line

Outside: wooden case for the fried instant noodle production line (adopt the wooden case or wooden pellets based on the clients’ need)

Service

1.1year complete warrantly

2.Free consulation serivice before during and after sales

3.Provide basic prodution techniques and formules

4.Overseas installation and training of equipment maintance and operating personally

5.Debugging and inspecting of equipment until everything is functional before leaving the fcatory