- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

AIRWOODS

-

Cleanliness:

-

Class100-10000 Customized

-

Air purification:

-

High Efficiency Filter and HEPA Diffuser

-

Chiller:

-

Modular Air-cooled Scroll Chiller

Quick Details

-

Weight (KG):

-

2000

-

Core Components:

-

design solution

-

Place of Origin:

-

China

-

Brand Name:

-

AIRWOODS

-

Cleanliness:

-

Class100-10000 Customized

-

Air purification:

-

High Efficiency Filter and HEPA Diffuser

-

Chiller:

-

Modular Air-cooled Scroll Chiller

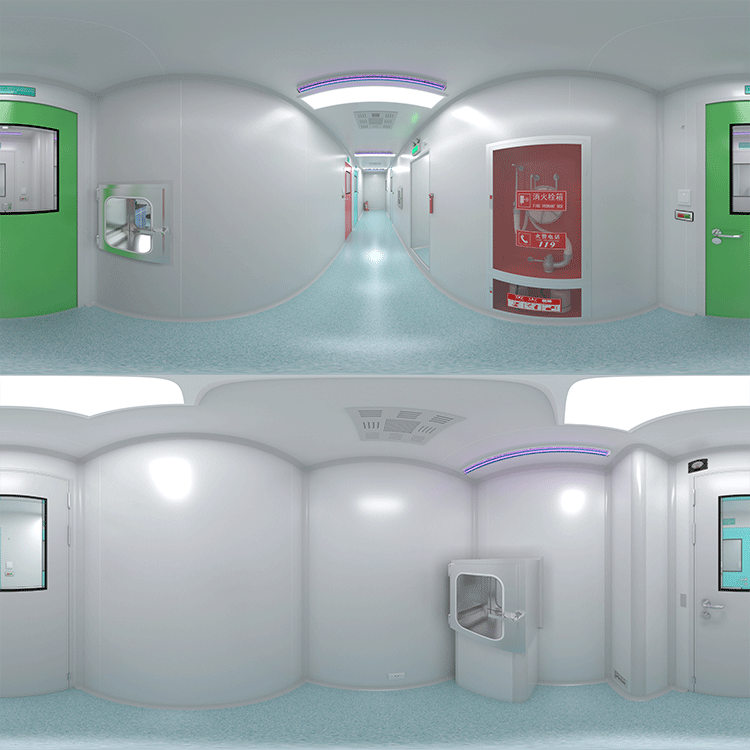

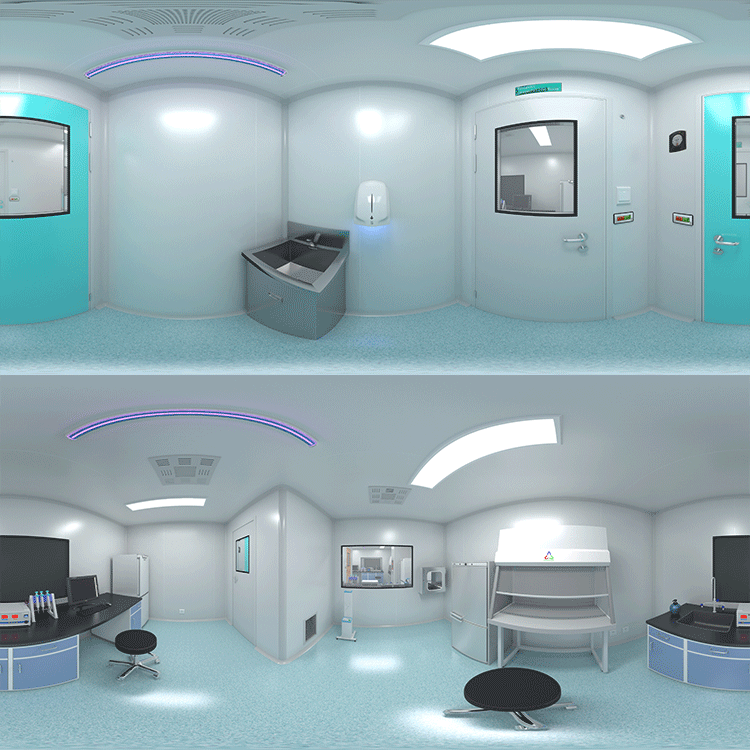

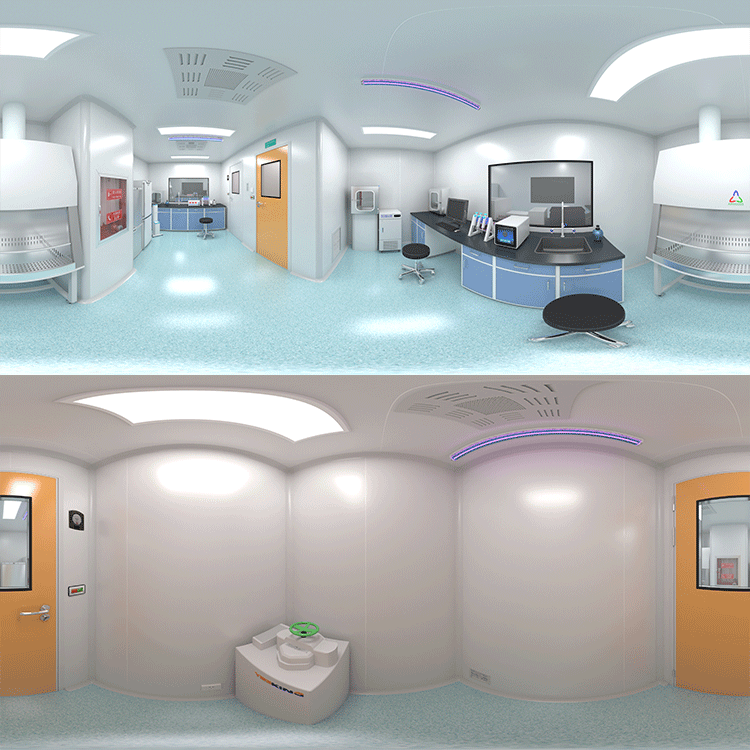

Cleanroom Cases

Cleanroom Service

We are not only the AHU supplier for HVAC system,

but also a turnkey solutioner for Different Project In domestic and abroad.

* Hospital Site Survey

* Hospital HVAC System Consultancy

* Hospital HVAC System Design

* Hospital HVAC System Equipment and Materials Supply

* Site Installation and Commissioning

* Site Tranining

* Aftersales Support

Cleanroom Introduction

Cleanrooms are essential to any manufacturing process where particulate contamination can affect the quality of goods produced.

Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect consumers from any potential flaw or mishandling of a product.

Additionally, clean room classifications require that positive pressure is continuously maintained while the cleanroom is operational. This process prevents contaminated air from flowing back within the clean air environment. This process allows clean filtered air to continuously flows from clean to less-clean spaces, allowing for continual air movement.

Specific clean room classifications and ISO class code descriptions provide protective guidelines and secure environments through controlled air filtration, which lowers the possibility of product contamination or large particulate interference within critical process manufacturing. Specific cleanroom requirements and ISO 14644-1 cleanroom standards are used to protect consumers from any potential flaw or mishandling of a product.

Additionally, clean room classifications require that positive pressure is continuously maintained while the cleanroom is operational. This process prevents contaminated air from flowing back within the clean air environment. This process allows clean filtered air to continuously flows from clean to less-clean spaces, allowing for continual air movement.

Specification

Airwoods Cleanroom turnkey project Service Scope:

|

Cleanroom Project Scope(from structure, HVAC,electric to autoc ontrol)

|

1. Cleanroom Structure: Wall Panel, Ceiling Panel, Windows, Doors, Fttings, Flooring

|

|

|

2. HVAC: AHU, Chiller, dehumidifier, Ducting, Piping, etc.

|

|

|

3. Electric: Lighting, Switch, Cables, Wires, Power Distribution Cabinet, etc

|

|

|

4. Auto- control: PLC Controller, Sensors for Humidity and Temperature, Control Panel

|

|

|

5. Process Piping System: Gas, Water Pipeline

|

|

Equipment

|

Air shower, Cargo shower, Mist shower, Dynamic pass box, Static pass box, Sampling booth,Weighing booth, Dispensing booth, Medicine stability test chamber, isolator, VHP sterilizer,Biological safety chamber, FFU, LAF, etc.

|

|

Temperature

|

21-27*C (or as per required)

|

|

Humidity

|

30-60°C (or as per required)

|

|

Application

|

Pharmaceutical factory, hospital, medical device factory, electronics factory, food factory,cosmetics factory, etc.

|

|

Qualification Documents

|

CE GMP ISO

|

|

Full Service

|

FAT and SAT Service, Professional Consultation, Training, 24 hours technical support

|

Cleanroom Equipment

Hot Searches