- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Processing capacity:

-

Diameter 19-42mm

-

Punching degree:

-

0-180°

-

Voltage:

-

380V/50Hz

-

Oil pressure:

-

≤120kg/cm2

-

Production capacity:

-

3-5s/pcs

-

Motor power:

-

4kw

-

Weight:

-

500kg

-

Dimensions:

-

950x1450x1435mm

-

Item:

-

Single Head Tube Arc Forming Tools Tube Pipe End Forming Machines

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

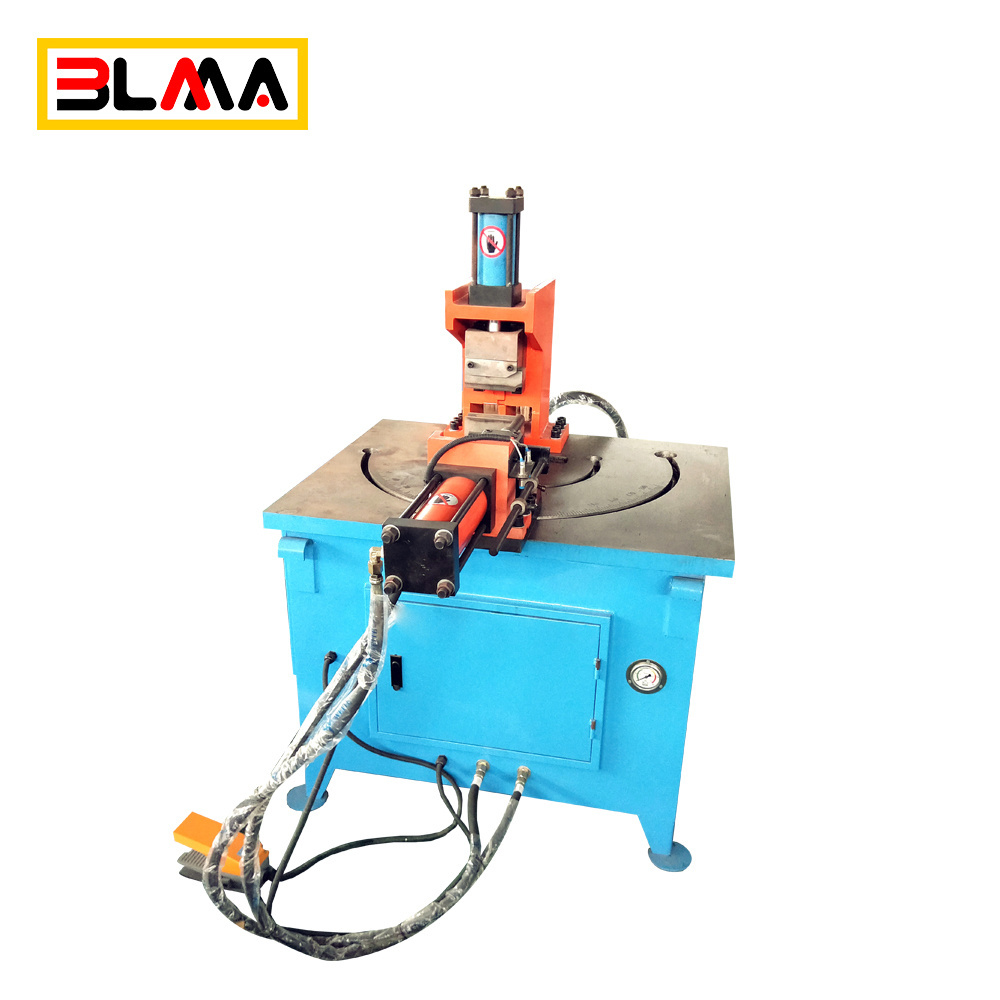

Brand Name:

-

BLMA

-

Machine Type:

-

arc forming machine

-

Weight (KG):

-

1200

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Processing capacity:

-

Diameter 19-42mm

-

Punching degree:

-

0-180°

-

Voltage:

-

380V/50Hz

-

Oil pressure:

-

≤120kg/cm2

-

Production capacity:

-

3-5s/pcs

-

Motor power:

-

4kw

-

Weight:

-

500kg

-

Dimensions:

-

950x1450x1435mm

-

Item:

-

Single Head Tube Arc Forming Tools Tube Pipe End Forming Machines

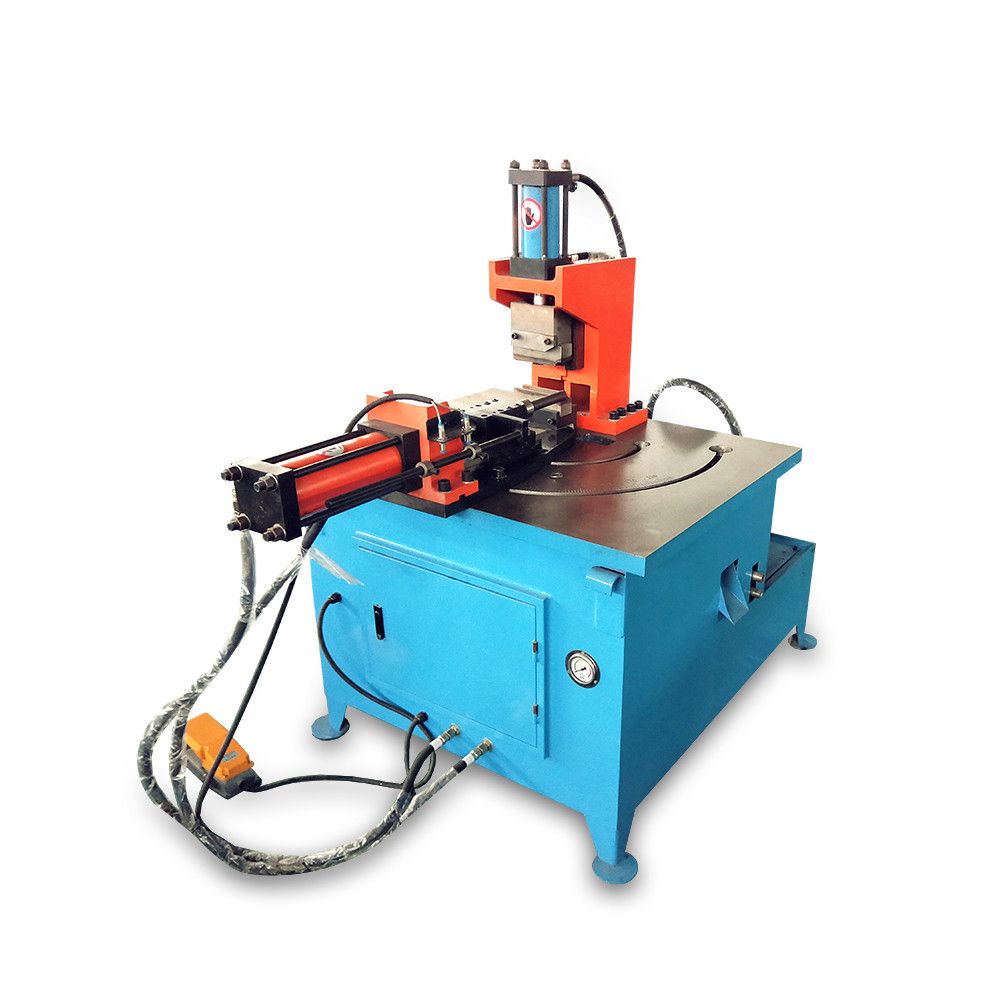

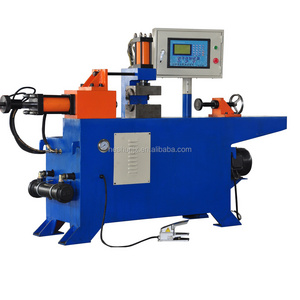

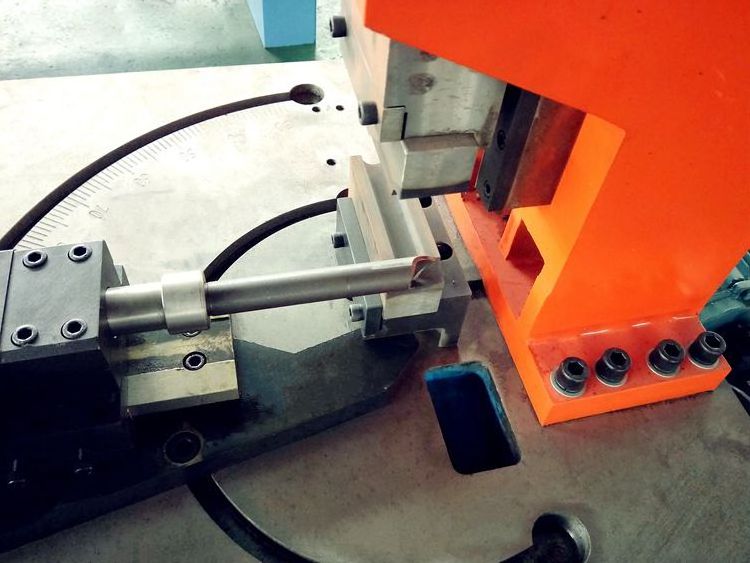

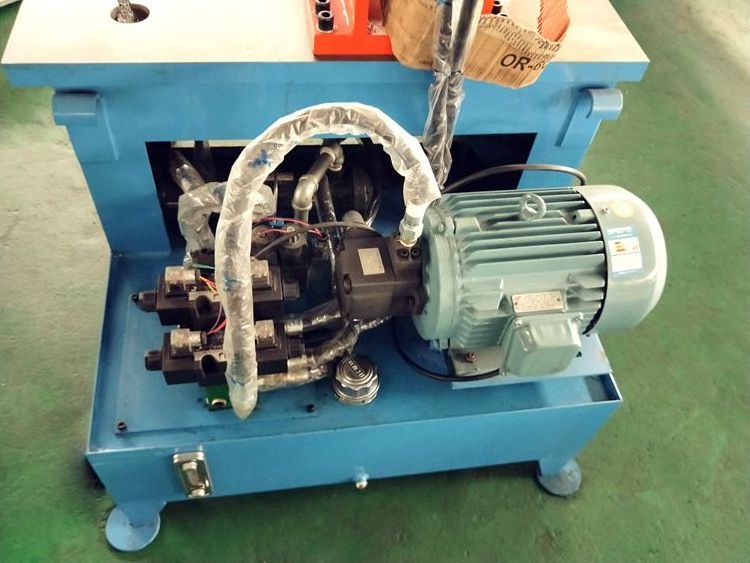

Single Head Tube Arc Forming Tools Tube Pipe End Forming Machines

Main features of CH40 pipe end forming machine:

- Suitable for steel and stainless steel pipes arc punching.

- Curvature can be arbitrarily adjusted.

- Hydraulic system is very stable.

- Good accuracy,high efficency,easy operation.

| Parameters | |

| Item | Hydraulic Round Square Pipe 2 Point Punching Press Automatic CNC Punching Machine |

| Model | CH40 |

| Processing capacity | Ø19-42mm |

| Punching degree | 0-180° |

| Voltage |

380V/50Hz |

| Oil pressure | ≤120kg/cm2 |

| Production capacity | 3-5s/pcs |

| Motor power | 4kw |

| Weight | 500kg |

| Dimensions | 950x1450x1435mm |

Pipe end forming machine Packaging: Each set in an exported standard wooden case.

Delivery time: Within 20 days after receiving deposit.

| Pre-service: |

| 1.We will help you confirm the model of our machine according to your offered pipe information. |

|

2.You are very welcome to see our machine how to work in the factory before you place an order with us. |

| Aftersales-service: |

| 1.Free installation, trial start and adjustment, training. |

|

2.We guarantee machine quality for one year. During this year, if spare parts of the machine were damaged, we can send the components to the customer by DHL,TNT freely. |

|

3.Our factory provide the service for the customer forever, if the customer need operation help,we provide 24 hours on-line reply service. |

1. How to choose the pipe end forming machine?

You have to inform us following details:

- Max. outside diameter

- Wall thickness range

- The pipe material

- The drawings if possible

2.Do you provide any training to make sure our user can operate the machine very well?

1)We will provide detailed video and instruction book for this machine;

2)We also offer training in our factory to all the clients,and we will arrange everything for you during these days in our city,to make sure every client will be the expert in using our machine!

3. How long warranty can you provide?

Our machine warranty is one year,and we use all the stable compoenents with long working life!

And we can also send our technician to do the after-sale service in client's factory!

4.What kind of solution you can offer to make sure your pipe bending machine can do our job?

1)We will help you confirm the model of our machine according to your offered pipe information.

2)Before you start the order for this big value machine,you can offer your workpiece drawing to us.

We can design the tooling to make your products in our workshop,after you are sure that the workpiece is good,then we can confirm the order finally.

3)You can visit us to check how to bend your product before you start the order.During this period, you can also learn how to use this machine well!