- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DOING

-

Weight:

-

500 KG

-

Year:

-

2023

-

Name:

-

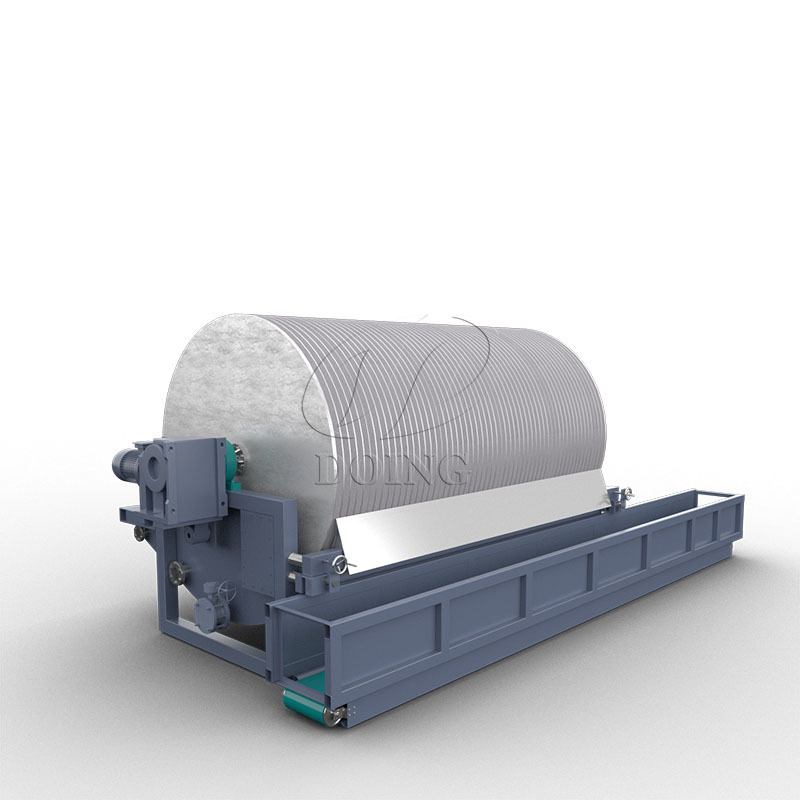

Vacuum filter

-

Suitable for:

-

Potato starch production line

-

Function:

-

Dewatering

-

Feature:

-

Effectively prevents misoperation

-

Advantage:

-

Advanced technology

-

Material:

-

Stainless Steel

-

Package:

-

Wooden Case

-

Related machine:

-

Cassava processing machine

-

Brand:

-

DOING

-

Quality:

-

Top Level

Quick Details

-

Applicable Industries:

-

potato starch dehydrating machine

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DOING

-

Weight:

-

500 KG

-

Year:

-

2023

-

Name:

-

Vacuum filter

-

Suitable for:

-

Potato starch production line

-

Function:

-

Dewatering

-

Feature:

-

Effectively prevents misoperation

-

Advantage:

-

Advanced technology

-

Material:

-

Stainless Steel

-

Package:

-

Wooden Case

-

Related machine:

-

Cassava processing machine

-

Brand:

-

DOING

-

Quality:

-

Top Level

Video Description

Machine Introduction

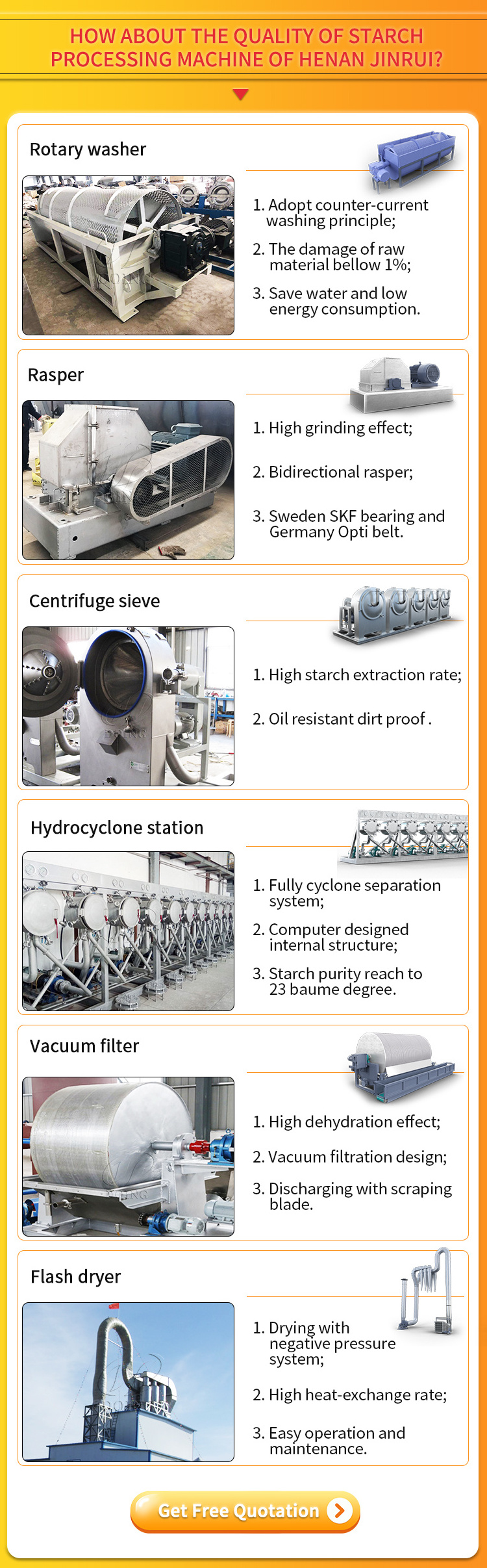

Vacuum filter is widely used starch dewatering machine in starch production process such as potato and sweet potato. The utility model has the advantages of compact structure, convenient operation, labor saving, power saving, low rotation speed, no vibration and less mechanical failure. After a large number of users actually use, it proves that this starch dewatering machine has high output and good dehydration effect (starch moisture content is 37-38% after dehydration). The dehydrated starch is in the form of fragments and easy to dry. It is an ideal starch dewatering machine for the potato starch processing industry.

This starch dewatering machine use the suction force of the vacuum pump, forming a certain negative pressure inside the drum, so that the starch adheres to the drum filter cloth. The drum rotates continuously at low speed to form a certain thickness of starch on the filter cloth. The water is absorbed by the vacuum pump, and the starch is automatically scraped off by the scraper to achieve the purpose of starch dehydration.

Inner Structurer

The vacuum dewatering machine is mainly composed of a hollow rotating drum, a stirring device, a transmission device and a vacuum pump. This starch dewatering machine adopts the principle of vacuum negative pressure adsorption. When working, the rotating drum is driven by the speed regulating motor. The wet starch is adsorbed on the filter cloth of the rotating drum. When a certain thickness is reached, the fixed scraper scrapes off the solid matter, and the filtrate enters the steam and water separation in order to achieve the purpose of separation of starch, water and gas. It is suitable for filtration equipment with small particle size, difficult to precipitate, specific general particle size, filter material thickness up to 3mm, and continuous suction filtration dehydration under vacuum.

Our Advantages

1. Low energy consumption and high output. It can process 0.5-10 tons of starch per hour. The electricity consumption is only 30% of traditional equipment;

2. No fault continuous operation, thus ensuring the continuity of the entire potato starch production line;

3. No need to manually unload, saving labor, reduce labor intensity;

4. Using elastic scraper, starch removal rate is higher;

5. The starch dehydration rate is high, the maximum vacuum of the starch dewatering machine can reach -0.08MPa, the starch dehydration effect is better, and it is convenient for the next step.

6. Using suction filtration, relative to other dehydration methods, this starch dewatering machine can improve the clarity of starch, and no interlayer phenomenon.

7. The drum adopts stepless speed regulation, which can be easily adjusted according to different starch properties.

8. Cost-effective, breaking the traditional vacuum dehydrator expensive price, DOING starch dewatering machine sales at factory price, with excellent starch dewatering performance.

2. No fault continuous operation, thus ensuring the continuity of the entire potato starch production line;

3. No need to manually unload, saving labor, reduce labor intensity;

4. Using elastic scraper, starch removal rate is higher;

5. The starch dehydration rate is high, the maximum vacuum of the starch dewatering machine can reach -0.08MPa, the starch dehydration effect is better, and it is convenient for the next step.

6. Using suction filtration, relative to other dehydration methods, this starch dewatering machine can improve the clarity of starch, and no interlayer phenomenon.

7. The drum adopts stepless speed regulation, which can be easily adjusted according to different starch properties.

8. Cost-effective, breaking the traditional vacuum dehydrator expensive price, DOING starch dewatering machine sales at factory price, with excellent starch dewatering performance.

Technical Parameter

|

Model

|

XDL04

|

XDL06

|

XDL12

|

XDL16

|

XDL20

|

XDL24

|

XDL30

|

|

Filter area(m²)

|

4

|

6

|

12

|

16

|

20

|

24

|

30

|

|

Filter area(m²)

|

0.04-0.08

|

0.01-0.08

|

0.04-0.08

|

0.04-0.08

|

0.04-0.08

|

0.04-0.08

|

0.04-0.08

|

|

Capacity(t/h)

|

1

|

1.5

|

3

|

4

|

6

|

8

|

12

|

|

Power(kw)

|

2.2+0.75

|

2.2+0.75

|

3+1.1

|

5.5+1.1

|

5.5+1.5

|

7.5+1.5

|

7.5+2.2

|

|

Max rotary speed(r/min)

|

11

|

11

|

11

|

11

|

11

|

11

|

11

|

|

Weight(kg)

|

1300

|

1500

|

2800

|

3100

|

3500

|

5000

|

6500

|

Recommended Products

Project Case

About Us

Hot Searches