- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

W700 x H1500 x L6000mm

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Free spare parts

-

Exhaust:

-

15000 M3/Hr(150mm/Aq)

-

fan type:

-

Anti-explode Fan

-

Booth Carbin material:

-

polypropylene

-

Fluorescent lamp:

-

40W

-

Cartridges filter:

-

12pcs

-

Booth the average wind speed:

-

0.5M/Sec.(150mm/Aq)

-

Weight:

-

4000KGS

-

Certification:

-

CE

Quick Details

-

Machine Type:

-

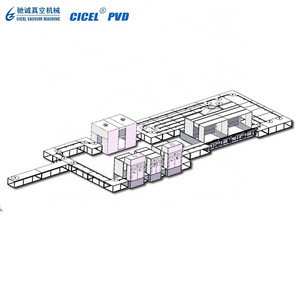

Automatic pp spraying curing line, Spray Booths, Powder coating line

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

COLO

-

Voltage:

-

380V

-

Power:

-

Multi Power

-

Dimension(L*W*H):

-

W700 x H1500 x L6000mm

-

Weight (KG):

-

1000

-

After-sales Service Provided:

-

Free spare parts

-

Exhaust:

-

15000 M3/Hr(150mm/Aq)

-

fan type:

-

Anti-explode Fan

-

Booth Carbin material:

-

polypropylene

-

Fluorescent lamp:

-

40W

-

Cartridges filter:

-

12pcs

-

Booth the average wind speed:

-

0.5M/Sec.(150mm/Aq)

-

Weight:

-

4000KGS

-

Certification:

-

CE

Product Description

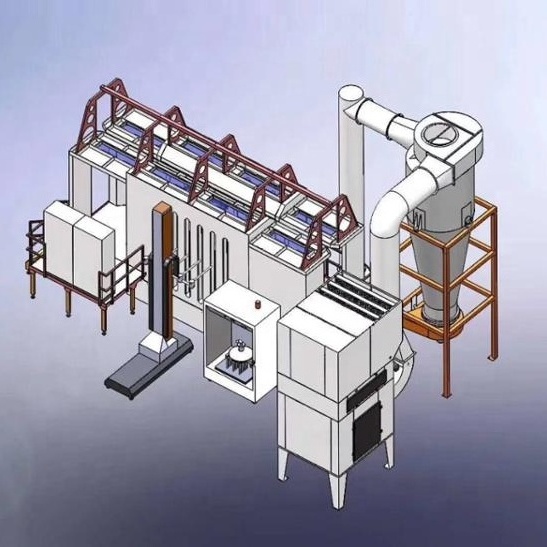

Automatic pp spraying curing line /vacuum metallizing painting machine /varnish painting line

Insulated plastic, antistatic and non-stick;

Saves time to clean the powder when changing color, so it is fast and easy for color changing.

Better powder recycling efficiency to make full use of the recycle powder and reduce the powder coating cost;

Good-look appearance, round corner and welding plastic construction make workers easier to clean the powder.

Saves time to clean the powder when changing color, so it is fast and easy for color changing.

Better powder recycling efficiency to make full use of the recycle powder and reduce the powder coating cost;

Good-look appearance, round corner and welding plastic construction make workers easier to clean the powder.

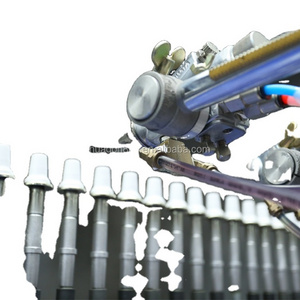

Details Images

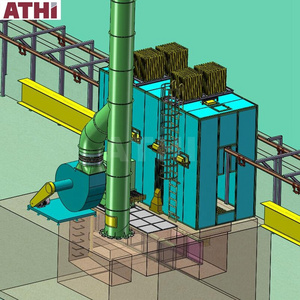

Main parts of the Plastic powder coating booth, match with mono-cyclone for high powder coating recovery efficiency.

Cyclone recovery stage with secondary filter recovery stage.

Maximize powder utilization for multi-color applications.

Booth size and configurations can be designed as requests.

Automatic pp powder coating booth applications

This automatic spray booth is ideal for big and continuous powder coating production, whose cyclone design maximizes efficiency during color change, minimal powder waste in process at all times due to highest transfer efficiency and air cleaning system contributing to a clean, safe coating environment.

Specification

|

Type

|

Powder Coating Booth

|

|

Substrate

|

metal

|

|

Condition

|

New

|

|

Machine Type

|

Automatic pp spraying curing line

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Marketing Type

|

Hot Product 2019

|

|

Warranty of core components

|

1 Year

|

|

Core Components

|

PLC

|

|

Coating

|

Powder Coating

|

Related Products

Customer Feedback

Product packaging

Standard and Safety Export Packages

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Inside with environment-friendly soft bubble paper , EPE foam wrapped well, carton outside for the delivery.

Hot Searches