- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongde

-

Model Number:

-

Customized

-

Power:

-

2 Kw

-

Voltage:

-

Requirements, Requirements

-

Dimension(L*W*H):

-

8000*1600*1700mm

-

Weight:

-

1.5 T

-

Warranty:

-

1 Year

-

Certification:

-

CE/ISO9001

-

Name:

-

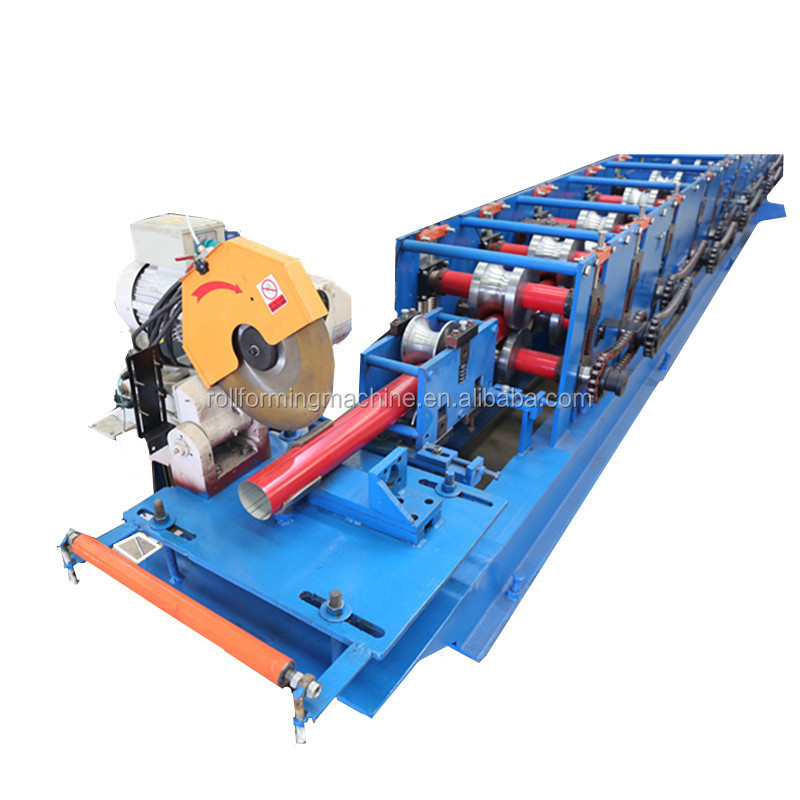

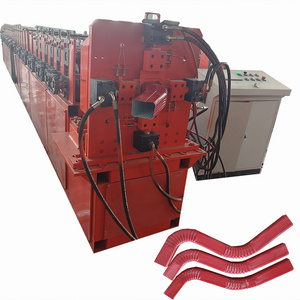

Rain gutter downspout elbow roll forming machine

-

Raw material:

-

PPGL

-

Usage:

-

Building

-

Color:

-

Blue or Custimized

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Outer Diameter: 85mm

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Certifications:

-

CE, ISO, SGS

Quick Details

-

Type:

-

square downpipe cold roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

6-7m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongde

-

Model Number:

-

Customized

-

Power:

-

2 Kw

-

Voltage:

-

Requirements, Requirements

-

Dimension(L*W*H):

-

8000*1600*1700mm

-

Weight:

-

1.5 T

-

Warranty:

-

1 Year

-

Certification:

-

CE/ISO9001

-

Name:

-

Rain gutter downspout elbow roll forming machine

-

Raw material:

-

PPGL

-

Usage:

-

Building

-

Color:

-

Blue or Custimized

-

Control system:

-

PLC(imported Brand)

-

Roller material:

-

45# Forged Steel

-

Shaft material:

-

45# Steel Outer Diameter: 85mm

-

Cutting blade material:

-

Cr12 Frequency Quenching

-

Certifications:

-

CE, ISO, SGS

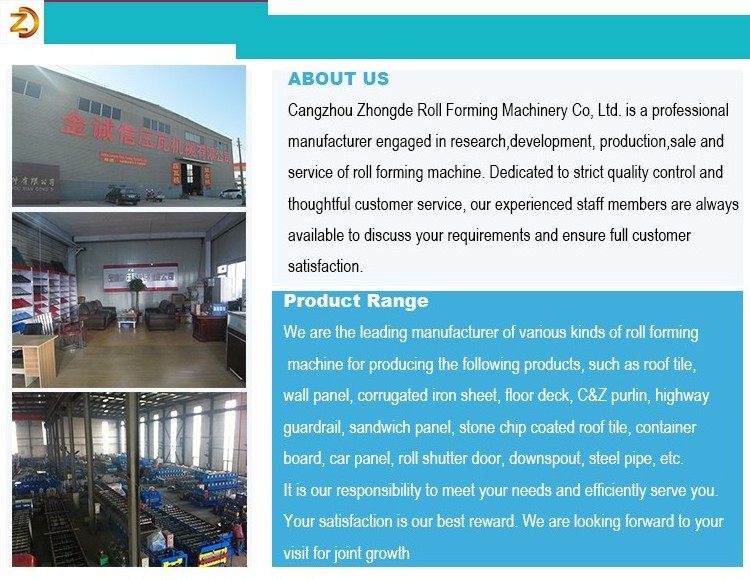

product information

Technical parameters

Usage Ceiling, wall, roof and structure frame

Roller steps 15

Dimension 7500*1600*1550mm

Weight 5t

Feeding width 1200mm

Forming thickness 0.28-0.8mm

Large frame 400mm H-Beam

Diameter of roller Φ80mm

Middle plate 16-25mm

Chain Size 1 inch

Voltage 380V 50HZ 3 phases or customized

Motor power 4kw

Pump station power 3kw/(7.5kw hydraulic motor)

Transducer power 3.5kw

Cutting system Hydraulic cutting(avoiding noise and smooth cut)

Material of cutting Cr12

Control system PLC brand :Panasonic

Length error : ±2mm

Production capacity 8-12m/min

Warranty 1 year and we provide technical support for whole life, and overseas service

Maintain Easily :Timely adding oil

Payment terms 30% in advance, the balance before delivery

Package Standard package

Delivery 35 days after receiving the deposit

work flow

Uncoiling→Feeding material into machine→Roll forming→Measuring length→Auto cutting→Products receiving

Decoiler

1.Features:

Mandrel and basement are the two components of the decoiler, the mandrel is shrinking expanding by mechanical device manually, after fix coil to mandrel, then put back the coil with mandrel together to basement.

2.Power: None

3. Power of the open and closure of segments: Mechanical

4.Power of rotation of segment: Pull by forming system

5.Number of segment: 4

6.Range of segment expansion: 480 ~ 520mm

7.Height of center of the mandrel: 0.65m

8.Feeding speed with push: 0~30m/min

9.Approximate Size: 1.5 m * 1.1m *1.2 m

10.Speed control: By mechanical brake

11.Methods of operation: Manual.

Material Feeder

1.Features: Ensure smooth& precise material feed.

2.Components: steel plate platform, two pitching rollers, position stopping block.

3. The coil is guided in the correct position and passed to the roll forming equipment.

Roll Forming System

Hydraulic cutting

1.Function: cutting action is controlled by PLC. The main machine automatically stops and the cutting will take place. After the cutting, the main machine will automatically start.

2.Power supply: hydraulic station

3.Frame: welding steel frame

4.Stroke switch: non-contact photoelectric switch

5.Cutting before forming: cut the sheet after roll forming to required length

6.Length measuring: automatic length measuring

Control system

The whole line is controlled by PLC and touch screen. The PLC system is with high-speed communication module, it is easy for operation. The technical data and system parameter can be set by touch screen, and it is with warning function to control the work of whole line.

1.Control the cutting length automatically

2.Automatic Length measurement and quantity counting

(precision 3m+/-3mm)

3.Voltage:380V, 3 Phase 60Hz (As per buyer`s request)

Output table

To Deliver the produced purlin into the bins

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Glazed Tile Making Machine

91.8% Response Rate

Decking Making Machine

91.8% Response Rate

Curving Bending Making Machine

91.8% Response Rate