- Product Details

- {{item.text}}

Quick Details

-

Production Capacity:

-

300bags/min

-

Weight (KG):

-

900

-

Voltage:

-

200V, 380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jike machinery

-

Dimension(L*W*H):

-

3920*670*1320mm

-

Type of machines:

-

Multi-function Automatic Packing Machine

-

Main Function:

-

Filling Sealing Wrapping Labeling

-

Usage:

-

Bag Making

-

Bag type:

-

Pillow Bag

-

Film material:

-

Laminatied Film

-

Sealing type:

-

Hot Sealing

-

Machine material:

-

Stainless Steel 304/Carbon Steel

-

Feature:

-

Easy Opperation

-

Automaticity:

-

Full-automatic

-

Control:

-

Famous Brand PLC+Touch Screen

Quick Details

-

Function:

-

FILLING, Wrapping, Labeling, Sealing

-

Packaging Type:

-

Film, Pouch

-

Packaging Material:

-

Plastic

-

Production Capacity:

-

300bags/min

-

Weight (KG):

-

900

-

Voltage:

-

200V, 380V

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Jike machinery

-

Dimension(L*W*H):

-

3920*670*1320mm

-

Type of machines:

-

Multi-function Automatic Packing Machine

-

Main Function:

-

Filling Sealing Wrapping Labeling

-

Usage:

-

Bag Making

-

Bag type:

-

Pillow Bag

-

Film material:

-

Laminatied Film

-

Sealing type:

-

Hot Sealing

-

Machine material:

-

Stainless Steel 304/Carbon Steel

-

Feature:

-

Easy Opperation

-

Automaticity:

-

Full-automatic

-

Control:

-

Famous Brand PLC+Touch Screen

Automatic Play Dough Packing Machine

Products Description

The JK-B model flow packing machine features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs.

The machine working starts with a cylindrical roll of film. The flow wrapping machine will transfer the film from the roll and through to the forming collar (sometimes referred to as tube or plow). At the same time, a conveyor has lined up individual products for wrapping. The film is fed through the collar and the product is surrounded with film, sealed and the film is then cut. The finished individual product is then gathered downstream to be bagged or cartoned prior to boxing and palletizing.

Main Features

1.Dual frequency conversion control, Bag length can be set and cut in one step, saving time and film.

2.Interface features easy and quick setting and operation.

3.Self failure diagnosis, clear failure display.

4.High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5.Temperature independent PID control, more suitable for packaging different materials.

6.Positioned stop function, without sticking knife or wasting film.

7.Simple driving system, reliable working, convenient maintenance.

8.All control is realized through software, easy for function adjusting and technical upgrade.

2.Interface features easy and quick setting and operation.

3.Self failure diagnosis, clear failure display.

4.High sensitivity photoelectric eye color tracing, numerical input of cutting sealing position for extra accuracy.

5.Temperature independent PID control, more suitable for packaging different materials.

6.Positioned stop function, without sticking knife or wasting film.

7.Simple driving system, reliable working, convenient maintenance.

8.All control is realized through software, easy for function adjusting and technical upgrade.

Machine Working Process

Bar Extrusion Machine

The extrusion molding device for bars consists of a hopper, extrusion barrel with a screw conveyor, die, and cutter. The device works by mixing the ingredients in the barrel, applying pressure to extrude the mixture through the die, and cutting it into individual bar lengths. The extruded bars are then cooled and solidified before further processing.

Conveyor System

The bars are then transported on a conveyor system, which moves them towards the packaging area. The conveyor may be equipped with guides or aligning mechanisms to ensure that the bars are properly positioned for packaging.

Film Unwinding

The packaging material, usually a roll of flexible packaging film, is mounted on the machine. The film unwinding system pulls the film from the roll, ensuring a continuous supply for packaging. The film passes through various components of the machine for forming, filling, and sealing.

Forming Section

In the forming section, the packaging film is shaped into a continuous tube. This is achieved by guiding the film through a set of forming collars or tubes that determine the width and shape of the packaging. The collars are adjustable to accommodate different bar sizes.

Sealing Section

Once the bars are in position, the packaging film is sealed to create individual pillow-shaped packages. The machine applies heat or pressure to seal the film along the edges, creating a secure package around each bar.

Cutting Section

After sealing, the continuous film tube is cut into individual packages. The machine typically uses a cutting mechanism, such as a rotary knife or reciprocating blade, to separate the packages from the film. The cutting section ensures that each package is cleanly separated and ready for further processing or packaging.

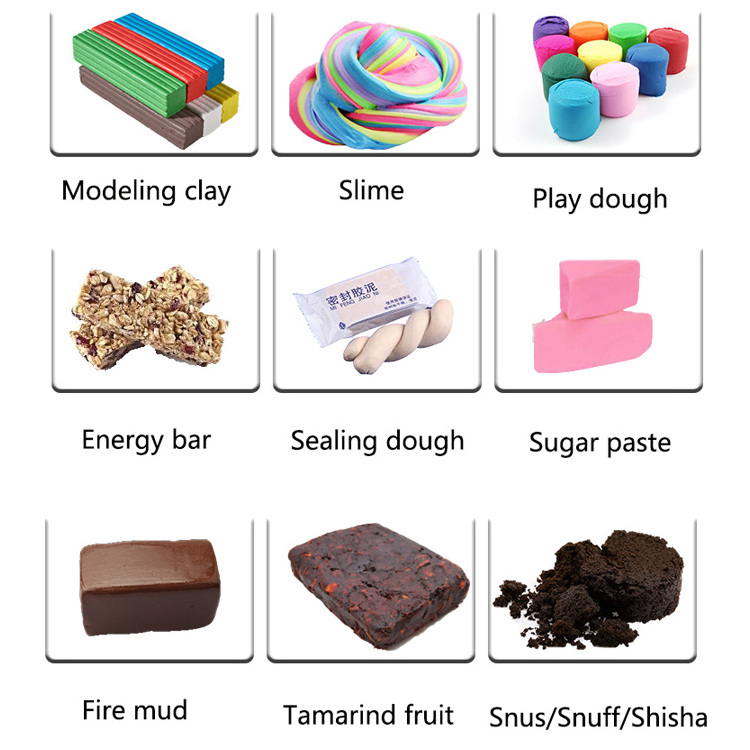

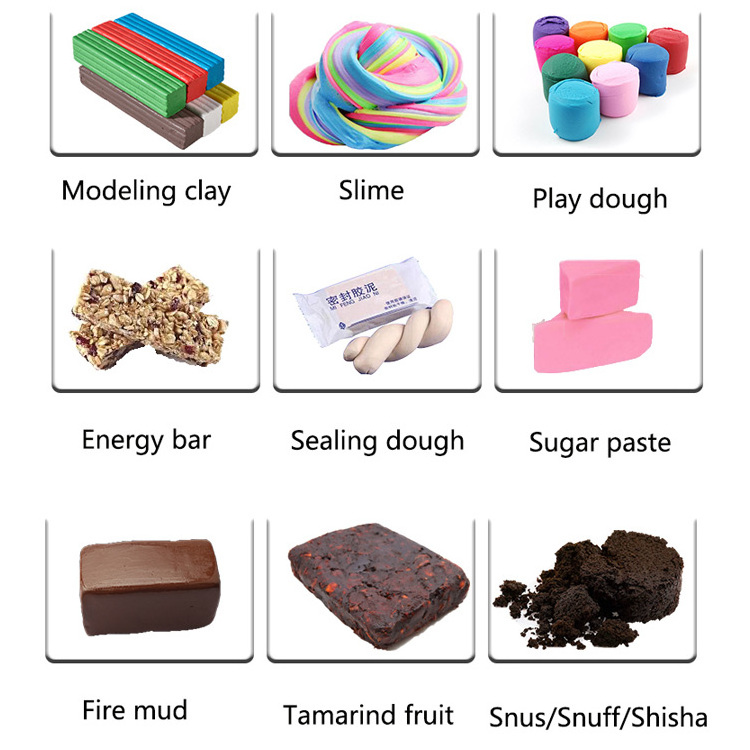

Packaging Effect Display

The packaging effect of the machine is beautiful, and the bag is well sealed.

Why Choose Us

JIKE BEE MACHINERY has a professional team to provide customers with various packaging solutions. Fully understanding the needs of customers,engineers design the most suitable solution. We have our own processing and assembly workshop and quality inspection and debugging process to ensure the quality of the machine.

After acceptance by the customer, they are packed in international standard wooden cases and shipped.

We will package the machine's instruction manual and a USB flash drive with machine operation videos together with the machine.

Ensure that you can use the machine as soon as you receive it. If you have something you don't understand, our after-sales team will also help you answer in time.

Ensure that you can use the machine as soon as you receive it. If you have something you don't understand, our after-sales team will also help you answer in time.

Our customers have covered more than 80 countries around the world.

And give us unanimous praise.

Hot Searches