- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Jinruifu

-

Motor Power:

-

5.5kw*2

-

Charging Capacity:

-

800L

-

Reclaiming capacity:

-

500L

-

Speed of Mixing Drum:

-

15r/min

-

Water Supply Mode:

-

Water Pump

-

Working Cycle Period:

-

1-2min

-

Discharge Way:

-

electric

-

Outline Dimension:

-

4300*2500*3900mm

-

Weight (KG):

-

2100 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

3500 Kg

-

Price:

-

Competitive Price

-

Votage:

-

380v

-

Discharging way:

-

Electric

-

Max of aggregate:

-

80mm

-

Standard:

-

GB/T1942-2000

-

Water motor:

-

0.75kw

-

Patent N0.:

-

ZL201320588509.3

Quick Details

-

Mixing Power:

-

5.5kw*2

-

Productivity:

-

25m3/h, 25m3/h

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinruifu

-

Motor Power:

-

5.5kw*2

-

Charging Capacity:

-

800L

-

Reclaiming capacity:

-

500L

-

Speed of Mixing Drum:

-

15r/min

-

Water Supply Mode:

-

Water Pump

-

Working Cycle Period:

-

1-2min

-

Discharge Way:

-

electric

-

Outline Dimension:

-

4300*2500*3900mm

-

Weight (KG):

-

2100 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Weight:

-

3500 Kg

-

Price:

-

Competitive Price

-

Votage:

-

380v

-

Discharging way:

-

Electric

-

Max of aggregate:

-

80mm

-

Standard:

-

GB/T1942-2000

-

Water motor:

-

0.75kw

-

Patent N0.:

-

ZL201320588509.3

Product Description

Patent No.:ZL201320588509.3

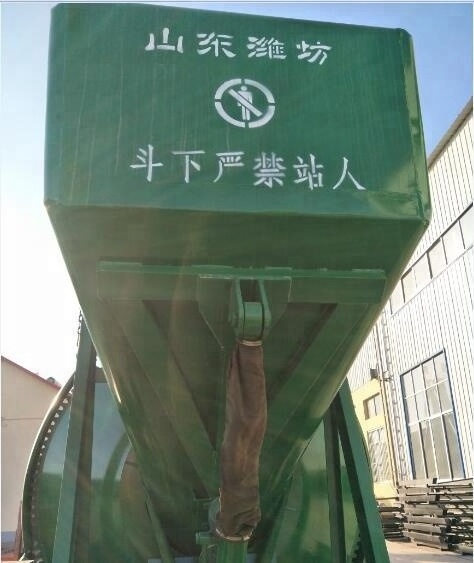

JZM/JZC SERIES Concrete mixer is self-falling type machine with double-cones counter-clockwise discharging.The drum rotates by rubber rollers.It can mix plastic and dry concrete.It is ideal equipment for big aggregate concrete mixing project.

1,Manual control.

2, Forward mixing & Reversal discharging.

3, The rubber roller drives the drum.

4, Can mix plastic concrete and low flow concrete.

5,Application: the construction of road or bridge; small and medium-sized concrete factory.

JZM/JZC SERIES Concrete mixer is self-falling type machine with double-cones counter-clockwise discharging.The drum rotates by rubber rollers.It can mix plastic and dry concrete.It is ideal equipment for big aggregate concrete mixing project.

1,Manual control.

2, Forward mixing & Reversal discharging.

3, The rubber roller drives the drum.

4, Can mix plastic concrete and low flow concrete.

5,Application: the construction of road or bridge; small and medium-sized concrete factory.

|

Model

|

JZC/JZM500

|

|

Reclaiming Volume (L)

|

500

|

|

Charging Volume (L)

|

800

|

|

Production Capacity (m3/h)

|

25

|

|

Mixing Motor (KW)

|

2*5.5

|

|

Lifting Motor (KW)

|

5.5

|

|

Water Pump Motor (KW)

|

0.55

|

|

Rotating speed ( r/min)

|

15

|

|

Mixing Blades Speed (r/min)

|

35

|

|

Discharge Way

|

Automatic

|

|

Tyre Size

|

650-16

|

|

Overall Weight (KG)

|

2100

|

Main Features

Compact structure design

Latest technology

Novel appearance

Nice seal,no leak

High wear-resistant material, durable

High efficiency

Good mixing effect

Easy installation and maintenance

Our Advantages

1. Improve the traditional feeding way, adopt the belt feeding mode, shorten the feeding process, and improve the working efficiency by 30%.

2. Less vulnerable parts, save steel wire rope, skip wheel, drum, easy to maintain.

3. The powder is transported by screw conveyor, reducing dust pollution and protecting the environment.

4. Save the electric motor, lower energy consumption and save electricity.

5. The equipment working process is safer.

6. Overcome the shortcomings of traditional hopper, wire rope damage and limit device failure.

7. Change the traditional drag-line mode, and pull the rod to expand and use without disassembling.

8. It can be used with the remote control, easier to operate, convenient and less artificial.

9. More practical.

10.OEM

2. Less vulnerable parts, save steel wire rope, skip wheel, drum, easy to maintain.

3. The powder is transported by screw conveyor, reducing dust pollution and protecting the environment.

4. Save the electric motor, lower energy consumption and save electricity.

5. The equipment working process is safer.

6. Overcome the shortcomings of traditional hopper, wire rope damage and limit device failure.

7. Change the traditional drag-line mode, and pull the rod to expand and use without disassembling.

8. It can be used with the remote control, easier to operate, convenient and less artificial.

9. More practical.

10.OEM

Our Company

Shandong Jinrui Heavy Industry Machinery Co.,Ltd

Shandong jinrui hevay industry machinery CO.,LTD was established in 2001, which is located in Anqiu,Shandong, China. It is only 160 kilometers way from Qingdao port, which is biggest prot in north of China. We specialized in construction machinery,which is including concrete mixers(including JZ series counter- rotary with double cones, JS series compulsory mixer with double lying shafts, LSY cement spiral conveyor, cement silo, PLD concrete proportioning MC series and concrete plant ETC).The concrete mixers

can be widely used in all kind of prefabrications, roads, bridges, ports and civil constructions and so on. The can mix stable soil concrete, plastic concrete, fluidity concrete, light aggregate concrete and mortars.

can be widely used in all kind of prefabrications, roads, bridges, ports and civil constructions and so on. The can mix stable soil concrete, plastic concrete, fluidity concrete, light aggregate concrete and mortars.

Now all the constuction MC have passed state quality standard GB9142-2000, and our company have passed international quality management ISO9001-2000.

We belive "customers foremost, credit first" and insist on providing satisfaction to the customers, we have created strong sales network all over the country and overseas covering east asia, southeast asia and africa.

※We are the manufacture.

※Near to Qingdao port.

※OEM acceptable.

※16 years of production experience and 6 years of exporting experience.

※Competitive price with high quality

※JINRUIFU is China top 10 famous brand

Main production:JZC series mixer, JS series mixer, concrete mixing plants and mobile concrete batching plant.

We have created strong sales network all over the country and overseas covering East Asia,South Asia and Africa.

We belive "customers foremost, credit first" and insist on providing satisfaction to the customers, we have created strong sales network all over the country and overseas covering east asia, southeast asia and africa.

※We are the manufacture.

※Near to Qingdao port.

※OEM acceptable.

※16 years of production experience and 6 years of exporting experience.

※Competitive price with high quality

※JINRUIFU is China top 10 famous brand

Main production:JZC series mixer, JS series mixer, concrete mixing plants and mobile concrete batching plant.

We have created strong sales network all over the country and overseas covering East Asia,South Asia and Africa.

Project Case

Packing & Delivery

Our Service

FAQ

Q: How about the quality of your products?

A: We are factory with more than 16 years of construction machinery manufacturing experience. All of our machines are manufactured strictly according to the national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q: How about the price?

A: We are manufactory, not dealer, so we can give you a lower price than those trade companies can.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

A: We are factory with more than 16 years of construction machinery manufacturing experience. All of our machines are manufactured strictly according to the national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.

Q: How about the price?

A: We are manufactory, not dealer, so we can give you a lower price than those trade companies can.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.

Q: Do you provide equipment operation training?

A: Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training. All of our engineers have passports.

Hot Searches