- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongtuo

-

Voltage:

-

Request

-

Power:

-

400kw

-

Weight:

-

6500 kg

-

Warranty:

-

2 Years

-

Material thickness:

-

0.5-3mm

-

cutting:

-

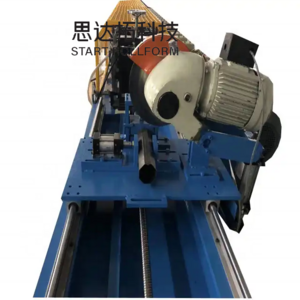

Flying saw tracking

-

For pipe thickness:

-

0.2~1.5mm

-

Assembly size:

-

21.5*1.1mm

-

Length Tolerance:

-

0-6mm

-

type:

-

HG32/HG50/HG76/HG127

-

voltage:

-

380V/ 415V/ 420V

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India

-

Certification:

-

ISO

Quick Details

-

Pipe Material:

-

Carbon steel

-

Marketing Type:

-

Hot Product 2020

-

Production Capacity:

-

0-90m/min

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

zhongtuo

-

Voltage:

-

Request

-

Power:

-

400kw

-

Weight:

-

6500 kg

-

Warranty:

-

2 Years

-

Material thickness:

-

0.5-3mm

-

cutting:

-

Flying saw tracking

-

For pipe thickness:

-

0.2~1.5mm

-

Assembly size:

-

21.5*1.1mm

-

Length Tolerance:

-

0-6mm

-

type:

-

HG32/HG50/HG76/HG127

-

voltage:

-

380V/ 415V/ 420V

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

India

-

Certification:

-

ISO

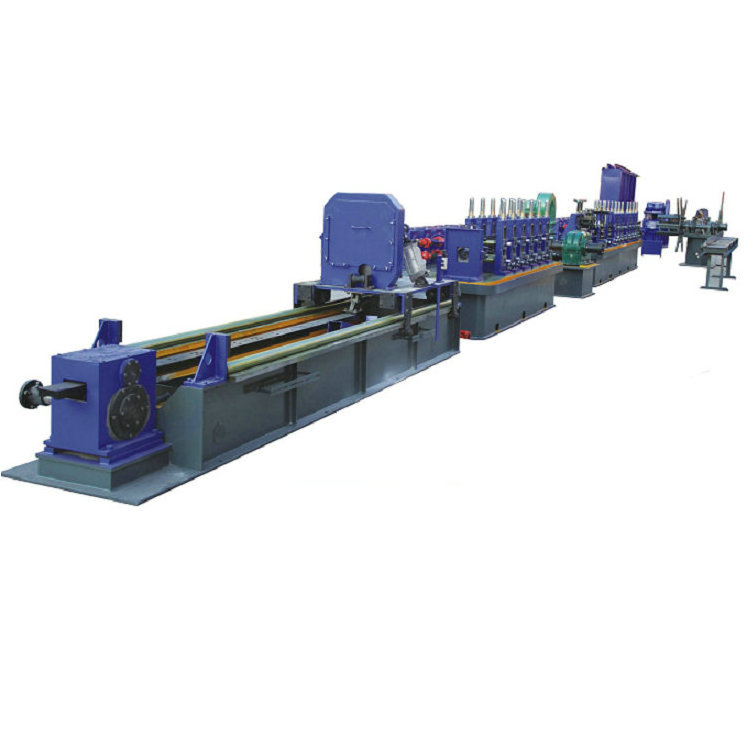

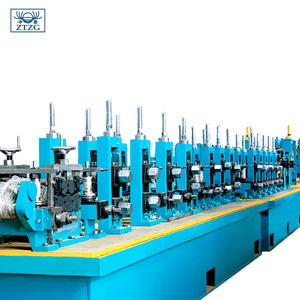

HG32/HG50/HG76/HG127 butt weld high frequency carbon steel tube pipe mill making machine

Summary of roll forming machine

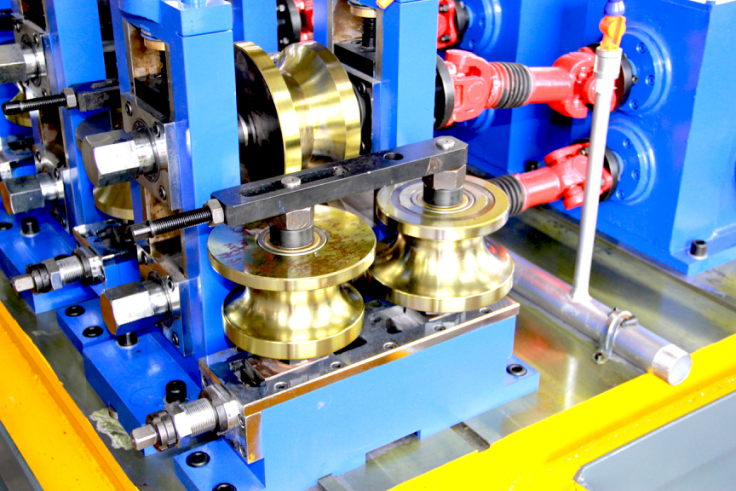

The welding pipe machine is intended for manufacturing of round pipe of Φ 16 mm-Φ 50 mm with thickness of 0. 5 mm–2. 5 mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths.

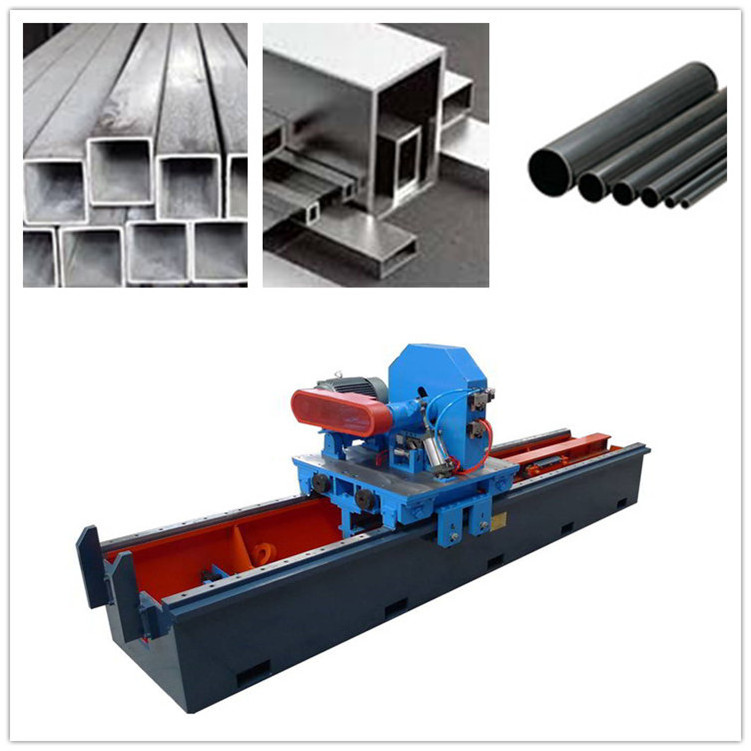

Finished product will be of round, square or rectangular pipe.

What is the Features of welding pipe machine ?

1.It supports many kinds of material like carbon steel, GI and others.

2.One welding pipe machine could make a large range of pipe sizes by changing mold.

3.One welding pipe machine could be used to make square pipe, round pipe by changing mold.

4.The pipe made by this kind of welding pipe machine could be used in many areas like water tube, wire pipe and others

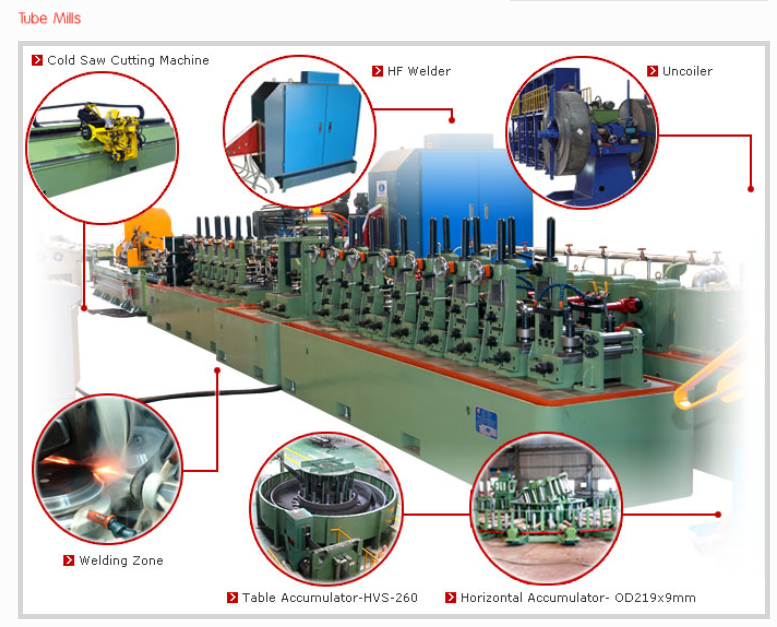

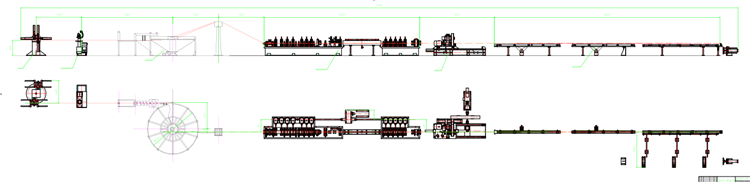

What is the working flow of welding pipe machine?

Steel Tape→→ Double-head uncoiler →→Strip-head Cutter and welder→→Spiral accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller)+ Removing External and internal burr→→Coo ling unit →→ Sizing unit and straightener →→Flying saw under computer-control →→ Run-out table

What is the specifications of welding pipe machine ?

|

name |

welding pipe machine |

|

a) Steel Pipe Specification |

|

|

Pipe diameter: |

Ø 16 –Ø 50 mm |

|

Pipe Thickness: |

0.5 – 2 .5 mm |

|

Square Pipe: |

1 4 X1 4 mm – 4 0X 4 0mm |

|

Rectangle Pipe: |

1 0 X20mm – 40 X 5 0mm |

|

Pipe Thickness: |

0.5 – 2. 0 mm |

|

Pipe Length: |

6-9m |

|

Length Tolerance: |

0- 3 mm |

|

b) Steel Tape Specification |

|

|

Material: |

Low Carbon steel (δb≤500Mpa, δs≤235Mpa) |

|

Steel Tape : |

|

|

Inner diameter: |

Φ580-Φ610mm |

|

Outer diameter: |

Φ900-1500mm |

|

Strip steel width: |

60mm- 20 0mm |

|

Strip steel thickness |

0.5 mm-2 .5 mm |

|

The maximum weight: |

3. 0 tons |

|

c) Electricity |

|

|

Dynamic power: |

AC380V±10%, 3phases, 50Hz±10% |

|

Control Power: |

AC220V±10%, one phase, 50Hz ±10% |

|

Electric installed capacity: |

appro 450KW |

|

e) Cooling water |

|

|

Reservoir for High Frequency equipment: |

15 m ³ , one set |

|

Reservoir for circulating cooling water: |

15 m ³ , one set |

|

f) Compressed air |

|

|

Pressure: |

0 . 4Mpa |

|

Flow: |

0 . 5m 3 /h |

|

g) Line speed: |

30-90m/min |

more details of welding pipe machine

two kinds of Shearing & butt welding machine

three types of spiral accumulator

two kinds of runout tables

.

How to invest the welding pipe machine plant?

If you want to invest welding pipe machine , you must pay attention on our suggestion as below:

It's better for you to invest 2 production lines at least. A lot of practice has proved that it is difficult to survive for one production ( except the profit is very high in your country). That is because the cost of one line and two lines are similar. One line is only less a Pipe Making Machine's price. On the other hand, the quantity of polishing machine is same. For example, we usually prepare one round pipe polishing machine and one square pipe polishing machine for the 1~4 pipe making machines. However, the other costs will vary by half such as the labor cost. A factory needs a skilled engineer with high salary at least if you employ him from China. However, if you have two production lines, the output will be doubled, Therefore, the more production lines, the lower production cost.

When you have two lines, you can also sell some pipes to the users.

we can also provide you steel coil slitting machine , which can produce narrow steel coils.