A. Standard seaworthy wooden box and pallet packing

B. Lead Time: Within 45 days after receiving deposit and order confirm.

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Havesino

-

Voltage:

-

380V 50Hz (customized)

-

Dimension(L*W*H):

-

3300mm*2550mm*1970mm

-

Weight:

-

4500 kg

-

Product name:

-

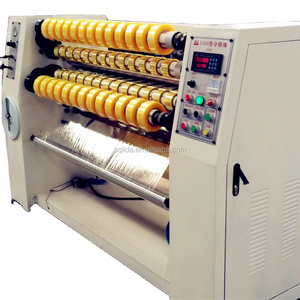

BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

-

SLITTING THICKNESS:

-

12-200 MICRO METER

-

Cutting speed:

-

500m/min

-

Cutting materials:

-

Hot stamping foil, primary film, laminates, paper, label, fabric

-

After-sales Service Provided:

-

7*24 hours online operation guide

-

UNWINDING DIAMETER:

-

MAX 800MM

-

UNWINDING TYPE:

-

SHAFTLESS 3 INCH AND 6 INCH

-

SLITTING WIDTH:

-

MAX 1600MM

-

REWINDING WIDTH:

-

MINI 40MM

-

REWINDING DIAMETER:

-

MAX 600MM

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

500 m/min

-

Max. workable width:

-

1300mm

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

Havesino

-

Voltage:

-

380V 50Hz (customized)

-

Dimension(L*W*H):

-

3300mm*2550mm*1970mm

-

Weight:

-

4500 kg

-

Product name:

-

BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

-

SLITTING THICKNESS:

-

12-200 MICRO METER

-

Cutting speed:

-

500m/min

-

Cutting materials:

-

Hot stamping foil, primary film, laminates, paper, label, fabric

-

After-sales Service Provided:

-

7*24 hours online operation guide

-

UNWINDING DIAMETER:

-

MAX 800MM

-

UNWINDING TYPE:

-

SHAFTLESS 3 INCH AND 6 INCH

-

SLITTING WIDTH:

-

MAX 1600MM

-

REWINDING WIDTH:

-

MINI 40MM

-

REWINDING DIAMETER:

-

MAX 600MM

Factory Direct Sale High Speed BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

Applicatioin:

The HN1600 is a

BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

suitable for a wide range of materials,

such as

primary film

,

laminates

(film t

o fil

m,

film to foil, fi

lm to paper),

hot stamping foil

, colding foil, holographic foils, metalized foil and other materials. This is our best selling and cost-effective

BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

.

Advanteges and Features of 0ur Slitting Rewinder Machine:

A. Auto Tension Control

B. Free Installing and Quick Operation Learning

C. 24*7 Hours Online Service

D. Stable Performance and Long Life Use

E. Random Adjust the Tightness of the Roll

F. Precise Slitting, Fast Speed, Perfect Edge Slitting

B. Free Installing and Quick Operation Learning

C. 24*7 Hours Online Service

D. Stable Performance and Long Life Use

E. Random Adjust the Tightness of the Roll

F. Precise Slitting, Fast Speed, Perfect Edge Slitting

At the same time, it is equipped with highly liberalized optional space and stable and durable

film slitting rewinding machine

accessories. The main parts of the whole machine are imported brands.

We provide reliable after-sales service. The warranty lasts for one year. When customers receive new machines, we provide on-site video guidance, we regularly visit customers abroad, and we provide free machine inspections for customers who are using our

BOPET/BOPP/CPP/OPP primary film roll Slitting Rewinding Cutter Machine

or other slitting machines.

|

Model

|

HN1600

|

|

slitting width

|

max 1600mm

|

|

slitting thickness

|

12-200 micro meter

|

|

unwinding diameter

|

max 800mm (optional:1000mm)

|

|

unwinding type

|

shaftless 3 inch and 6 inch

|

|

unwinding brake type

|

magnetic powder brake

|

|

rewinding width

|

mini 40mm

|

|

rewinding diameter

|

max 600mm (optional: 800mm)

|

|

working speed

|

max 500m/min

|

|

slitting unit

|

shavor blade (optional: shear circle blade)

|

|

unloading device

|

manual finished roll unloading device

(optional: auto turret vertical roll unloading device)

|

Rewinding Unit:

A.

3 inch slipping air shaft

B. Full width pressing rollers &

Small Individual Assistant Press Roller

C. Laser position light

D. Automatic tension control

Unwinding Unit:

A. 3 inch and 6 inch shaftless unwinding system

B. Magnetic powder brake with load cell close loop system

C. Back control button&screen display

A. 3 inch and 6 inch shaftless unwinding system

B. Magnetic powder brake with load cell close loop system

C. Back control button&screen display

D. EPC edge guider

F. Material (primary film/lamination/hot foil stamping/paper...) Splice Table

Packaging of slitting machines

1. Fully test the machine before shipping to ensure that it is ready to use.

2.

Detailed operation video and paper instruction manual.

3. 1 year warranty on key parts.

4.

On-site video installation and operation training.

5.

24/7 engineering team technical support.

6. V

isit factory regularly for free machine inspections.

Our Product Categories

We offer a wide range of high-quality slitting machine

for buyers with slitting production demands, covering different materials and industries.

Materials We Can Slit

Depending on your needs, you can browse the material

you are interested in or need to cut to find the right machine .

If you don't have the options you want below, please send us a message.

HAVESINO is a pioneer in the development, design and manufacture of high quality and high performance primary film/composite material slitting and rewinding machines, core cutters and machines for the flexible packaging and labelling industry. We are a leader in providing optimal

solutions.

solutions.

HAVESINO's philosophy is "We Support You To Be Different. " We will be committed to giving you a new understanding of the machinery made in China. Efficient slitting changes products, and products change the world.

Since 2010, through our continuous joint efforts, we are committed to the design, manufacture and introduction of high-quality, professional machines and materials. We provide OEM services, can manufacture machines according to customer needs, and can customize packaging for customers. All projects will be completed by our professional engineers in the Mechanical Engineering Department, Assembly Department, Electrical Department, Software Programming Department. We've installed hundreds of machines around the world and thousands of factories around the world are already using our machines.

Today, Havesino is still focused on research and development and technological innovation, and is committed to manufacturing the world's highest quality slittling and automatic production machinery. The sale of the machine is not the end of the transaction. We always believe that professional knowledge, meticulous service, accurate market information, reasonable prices, these will make us long-term cooperation. We will always support and assist you in your further success!

Today, Havesino is still focused on research and development and technological innovation, and is committed to manufacturing the world's highest quality slittling and automatic production machinery. The sale of the machine is not the end of the transaction. We always believe that professional knowledge, meticulous service, accurate market information, reasonable prices, these will make us long-term cooperation. We will always support and assist you in your further success!

Q.:Are you a factory or trading company?

A.: We are a factory and manufacturer. The factory is in Hangzhou, Zhejiang Province, China.

Q.:How does your factory do regarding qaulity control?

A.: We will strictly control the production quality and debug the machine many times before leaving the factory to ensure that you can put the machine into use immediately after receiving it to ensure the smooth progress of the production task.

Q.:How can I visit your factory?

A.: You can book your ticket directly to Hangzhou Xiaoshan Airport in Zhejiang Province, or to a nearby airport (such as Shanghai Hongqiao Airport, and then take the high-speed train to Hangzhou). We will pick you up at the airport or train station and take you to the factory.

Q.:What’s service or guarantee can you offer?

A.: 1 year warranty for key parts of the machine; Machine installation and operator training services; Lifelong free technical support; Material support.

A.: We are a factory and manufacturer. The factory is in Hangzhou, Zhejiang Province, China.

Q.:How does your factory do regarding qaulity control?

A.: We will strictly control the production quality and debug the machine many times before leaving the factory to ensure that you can put the machine into use immediately after receiving it to ensure the smooth progress of the production task.

Q.:How can I visit your factory?

A.: You can book your ticket directly to Hangzhou Xiaoshan Airport in Zhejiang Province, or to a nearby airport (such as Shanghai Hongqiao Airport, and then take the high-speed train to Hangzhou). We will pick you up at the airport or train station and take you to the factory.

Q.:What’s service or guarantee can you offer?

A.: 1 year warranty for key parts of the machine; Machine installation and operator training services; Lifelong free technical support; Material support.

Q: Is the machine hard to operate?

A.:

After learning the simple operation Settings of the screen and buttons, you can master how to use it. We will send you operation videos and instructions for your reference. We will install the machine before shipment. As long as the machine is powered on, it can be put into use immediately.

Q:Will it take long time to receive the machine?

A.: The lead time is 30-45 days after receiving the advance payment (according to the optional situation, etc.). Delivery time depends on destination and shipping efficiency.

Q:Why do I choose your machine?

A: High quality products, meticulous service, consistent industry reputation, these together achieved thousands of customers on our high evaluation. Everything has stood the test of time. We firmly believe that Havesino, with the slogan "We support you to be different", will make you very satisfied and have a memorable purchasing experience.

Q. Do not have professional technicians, do not know how to choose machine?

A.: Our business team are very professional, well-versed in product knowledge and we will choose the machine that best suits your current needs and introduce it to you in more details.

Q. Do not find the right machine structure to match your currently demand?

A.: In addition to the optional customization of existing models. We can also customize the production according to your needs to ensure that it accurately matches your actual use scenario. We at Havesino have always put customers first for more than a decade, and always regard the needs of customers as our primary needs of development.

Q:Will it take long time to receive the machine?

A.: The lead time is 30-45 days after receiving the advance payment (according to the optional situation, etc.). Delivery time depends on destination and shipping efficiency.

Q:Why do I choose your machine?

A: High quality products, meticulous service, consistent industry reputation, these together achieved thousands of customers on our high evaluation. Everything has stood the test of time. We firmly believe that Havesino, with the slogan "We support you to be different", will make you very satisfied and have a memorable purchasing experience.

Q. Do not have professional technicians, do not know how to choose machine?

A.: Our business team are very professional, well-versed in product knowledge and we will choose the machine that best suits your current needs and introduce it to you in more details.

Q. Do not find the right machine structure to match your currently demand?

A.: In addition to the optional customization of existing models. We can also customize the production according to your needs to ensure that it accurately matches your actual use scenario. We at Havesino have always put customers first for more than a decade, and always regard the needs of customers as our primary needs of development.

Hot Searches