* Non-contact processing, durability;

* High precision, fast, high legibility, reliability;

* Forming a top-quality micro mark;

* Environment-friendly;

* Easy to use, strong security features;

* Strong traceability of products;

* High-speed automatic processing can be achieved ;

* The overall production cost of individual parts is far less than that of printing traditional inks.

- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C2H6

-

EINECS No.:

-

11016-17-4

-

Place of Origin:

-

Shenzhen China

-

Brand Name:

-

Domeanyway

-

Model Number:

-

DM-GB0031

-

Product name:

-

Plastic Laser Marking Additive

-

Form:

-

Granule

-

Color:

-

Black

-

Melt Flowing rate:

-

15.0-25.0 (g/10min. 190℃, 5KG)

-

Density(g/cm³:

-

1.3-2.1

-

Suitable Laser Wavelength(nm):

-

355-1064nm, 1070nm 10600nm(CO2 Laser)

-

Keywords:

-

Laser marking additive

-

Application:

-

Plastic Laser Marking

-

Sample:

-

Freely Provided

-

Grade:

-

Food Grade.Industrial Grade

Quick Details

-

CAS No.:

-

9002-88-4

-

Purity:

-

99%

-

Other Names:

-

The laser sensitivity additive

-

MF:

-

C2H6

-

EINECS No.:

-

11016-17-4

-

Place of Origin:

-

Shenzhen China

-

Brand Name:

-

Domeanyway

-

Model Number:

-

DM-GB0031

-

Product name:

-

Plastic Laser Marking Additive

-

Form:

-

Granule

-

Color:

-

Black

-

Melt Flowing rate:

-

15.0-25.0 (g/10min. 190℃, 5KG)

-

Density(g/cm³:

-

1.3-2.1

-

Suitable Laser Wavelength(nm):

-

355-1064nm, 1070nm 10600nm(CO2 Laser)

-

Keywords:

-

Laser marking additive

-

Application:

-

Plastic Laser Marking

-

Sample:

-

Freely Provided

-

Grade:

-

Food Grade.Industrial Grade

Product Description

Specification

|

Classification:

|

Chemical Auxiliary Agent

|

|

CAS No.:

|

9002-88-4

|

|

Place of Origin:

|

Guangdong, China

|

|

Type:

|

Adsorbent

|

|

Purity:

|

99%

|

|

Form:

|

master batch or powder

|

|

Function:

|

Laser marking/IR absorption

|

|

Usage:

|

Plastic Laser Marking

|

|

Dosage:

|

1%-5%

|

|

Product Name:

|

Laser Marking Additive

|

|

Other Name:

|

The laser sensitivity additive

|

|

Sample:

|

Provide Free Samples

|

|

Application:

|

Livestock Ear Tags, Security Seals, Plastic Parts etc.

|

DOME Laser Marking Additives

Top-Picks In Stock:

|

Product Name

|

Model No.

|

Compatibility

|

Dosage

|

Laser Type

|

|

Laser Marking Masterbatch - Black Mark on Color Plastic

|

DM-GW0032

|

Universal

|

1-5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GW0042

|

PP

|

1-5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GW0052

|

PC

|

1-5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GW0062

|

Universal

|

1-4%

|

UV Laser(355nm), Green Laser(532nm)

|

|

Laser Marking Masterbatch - White Mark on Black Plastic

|

DM-GB0031

|

Universal

|

0.5-0.6%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GB0041

|

PC

|

1-1.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GB0051

|

ABS

|

1-1.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GB0061

|

Universal

|

1-1.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

Laser Marking Masterbatch - Black Mark on Transparent Plastic

|

DM-GB0030

|

PP

|

1-1.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-GB0040

|

PC

|

1-1.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

Laser Marking Masterbatch - White Mark on Color Plastic

|

DM-GG0033

|

Universal

|

1-3%

|

UV Laser(355nm), Green Laser(532nm)

|

|

Laser Marking Powder - Black Mark on Color Plastic

|

DM-PW0036

|

Universal

|

0.2-0.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-PW0046

|

ABS

|

0.2-0.5%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

|

DM-PW0056HE

|

PBT

|

0.1-0.3%

|

Fiber Laser(1064nm), UV Laser(355nm), Green Laser (532nm)

|

|

Laser Marking Powder - White Mark on Black Plastic

|

DM-PB0037

|

Universal

|

0.2-0.5%

|

UV Laser(355nm), Green Laser(532nm)

|

Laser Marking Additive Application

The Laser Marking Additives Can be identified in: natural color plastic, white plastic, colored plastic, and black plastic laser

printing label has been successfully commercialized in applications including livestock ear, light switch cover, cosmetic

packaging materials, 3D Printing Materials, ABS keyboards, HDPE, viz., PET and PVC rigid containers and container lids for

automotive interior buttons and door knobs, dashboards, commercial machinery, nylon and PBT electrical connectors for automotive and non-automotive applications, hood components such as safes and air caps, anti-counterfeiting labels, tages, container latches, stationery, appliance shells and so on.

printing label has been successfully commercialized in applications including livestock ear, light switch cover, cosmetic

packaging materials, 3D Printing Materials, ABS keyboards, HDPE, viz., PET and PVC rigid containers and container lids for

automotive interior buttons and door knobs, dashboards, commercial machinery, nylon and PBT electrical connectors for automotive and non-automotive applications, hood components such as safes and air caps, anti-counterfeiting labels, tages, container latches, stationery, appliance shells and so on.

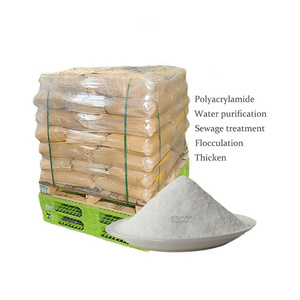

Packing & Delivery

* Caton Size: 50*38*20cm

* Weight: 20Kgs/caton

* Laser additive is packaged in a plastic box or a carton lined with a PE bag;

* Laser additive is non-dangerous goods;

* Please store in dry and ventilated conditions;

* Waterproof and moisture-proof;

* Avoid sun exposure;

* Please seal the unused portion of the Laser additive;

* Please use it up within 24 months.DELIVERY: DELIVERY: 2-7 WORKING DAYS

* Weight: 20Kgs/caton

* Laser additive is packaged in a plastic box or a carton lined with a PE bag;

* Laser additive is non-dangerous goods;

* Please store in dry and ventilated conditions;

* Waterproof and moisture-proof;

* Avoid sun exposure;

* Please seal the unused portion of the Laser additive;

* Please use it up within 24 months.DELIVERY: DELIVERY: 2-7 WORKING DAYS

Usage Notice of Laser Marking Additive

* First of all, the laser marking additive does not need to be baked. It is recommended to dry the raw materials first, and then add our laser marking additive, so that injection molding and laser engraving can be performed normally.

* Usually, if it is direct injection molding, it is recommended to use the laser marking additive masterbatch, because the powder is relatively heavy during injection molding, and if the dispersion is not uniform, the phenomenon of bottom sinking will occur. If it is a granulation process, the effect of using laser additive powder and laser engraving masterbatch is equally good.

* Marked white/Gold on Black: We require the raw materials is natural or transparent. Do not add other black colors, black masterbatch, black color paste, etc. during the marking process. The material is dyed black and then directly laser marked.

* Usually, if it is direct injection molding, it is recommended to use the laser marking additive masterbatch, because the powder is relatively heavy during injection molding, and if the dispersion is not uniform, the phenomenon of bottom sinking will occur. If it is a granulation process, the effect of using laser additive powder and laser engraving masterbatch is equally good.

* Marked white/Gold on Black: We require the raw materials is natural or transparent. Do not add other black colors, black masterbatch, black color paste, etc. during the marking process. The material is dyed black and then directly laser marked.

※

16 YEARS OF PRODUCTION EXPERIENCE ON PLASTIC INDUSTRY.

※

CUSTOMIZEDSERVICE ACCORDING TO YOUR INQUIRY.

※ ADVANCED EQUIPMENT FOR TESTING ADN MANUFACTURING.

※ COMPETITIVE FACTORY PRICE.

※ PROFESSIONAL SERVICE.

※

FAST DELIVERY AND FREE SAMPLES.

※ 24*7 HOURS AFTER-SALE SERVICE

DOME MAIN PRODUCTS:

Our company mainly specializes in the production of: Plastic Laser Marking Additives, PE / TPU / TPE / ABS / PP / LLDPE / HDPE / LDPE / PS / PA / PVC / EVA and other Plastic White/Black/Color Masterbatches, Defoaming Masterbatches, Filling Masterbatches, Nano-filling Masterbatches, Whitening Masterbatch, HIPS/ABS/PP/PE/PBT/TPU and other Modified Plastic Compounds.

PLASTIC LASER MARKING ADDITIVES

TPU RAW MATERIALS

COLOR MASTERBATCH

WHITE MATERBATCH

BLACK MATERBATCH

CUSTOM MODIFIED COMPOUNDS

FUNCTIONAL MASTERBATCH

FILLING MASTERBATCHES

DEFOAMING MASTERBATCHES

Hot Searches